- This topic has 16 replies, 4 voices, and was last updated 6 years ago by .

-

Topic

-

Feeling foolish with the predicament that I find myself in. Bought my boat 3 years ago. Raw water pump was leaking at survey and seller replaced with new. I went to do an impeller service this spring and found the leads going to the always on power studs/terminals for the ECM short and tight and in the way of being able to remove the raw water impeller. Removing the wires from the studs was going smooth then the nut on the + stud tightened up. I worked the nut back and forth, sprayed some kroil on it, worked it some more and snap. With the broken stud in my hand and my eyes not quite being what they used to be I could now see that someone, probably the builder had coated the exposed stud threads with liquid electrical tape.

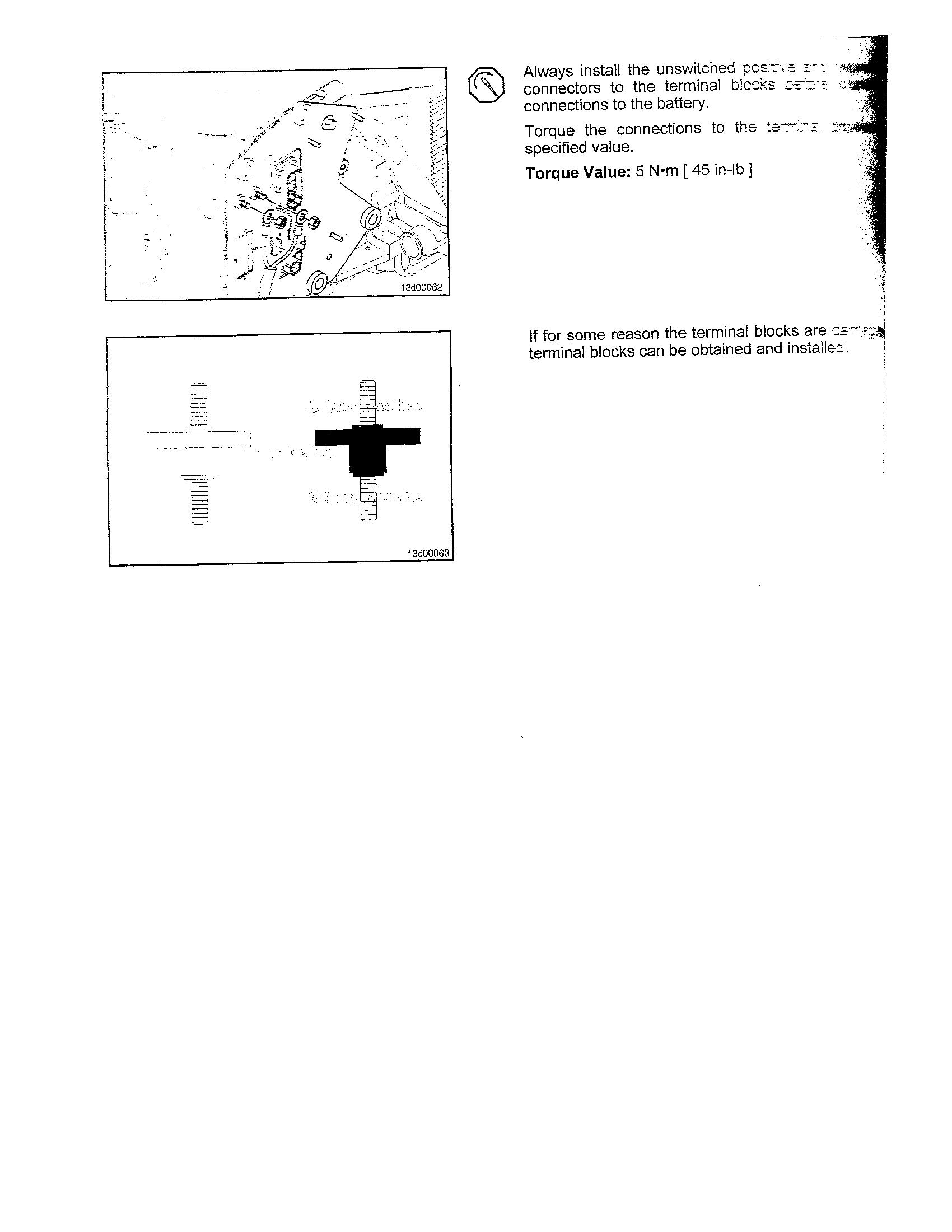

Long story short, I need to replace the positive stud and Cummins Northeast says that I have to buy the whole ECM and that the studs are not available on their own. The parts guy couldn’t believe this either and checked with the service guys who also said I had to buy a new ECM harness to get the stud (see picture below). This is totally insane!

My QSC Parts Catalog doesn’t list the studs, but the repair manual shows how to do R & R and comes right out and says that they are replaceable.

Any suggestions on where to turn? Maybe Seaboard can help? Thanks, Kevin

You must be logged in to reply to this topic.