Glendinning Throttle Controls – EEC3, EEC4, & Smart Actuator II

No matter what type of propulsion system your boat is equipped with – whether electronic or mechanical – Glendinning’s engine control systems takes the guess work out of deciding which control system is right for you.

- Electronically Governed Engines – the EEC-3 and EEC-4 systems provide complete control of electronically throttled and shifted engines.

- Mechanically Governed Engines – the Smart Actuator and Smart Actuator II systems provide complete control of mechanically throttled and shifted engines.

With the advent of electronically controlled engines in the marine industry, Glendinning has developed the complete controls system to be compatible with all types of electronically & mechanically governed engines and will provide the boat operator with total control over the boats propulsion system.

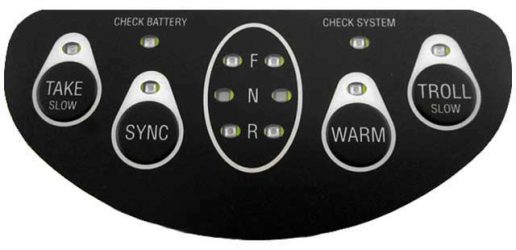

Glendinning EEC3 Control System – Electronic System with TROLL Mode

Glendinning has thought of everything today’s savvy boater wants in electronic engine controls. From ease of installation to reliable performance, COMPLETE CONTROLS™ has it all. Compare these features and benefits with our competition’s — we’re sure you’ll agree that our controls are COMPLETE.

- Single or Dual lever control

- Adjustable control head detent / friction settings

- “Posi-lock” gear lockout

- Selectable Station Transfer Methods

- Station Lockout Capability

- Adjustable High Idle Settings

- Control Head Keypad Lights Dimmer

- Dual Battery Inputs

- Audible neutral indicator

Glendinning EEC4 Control System – Electronic System without TROLL Mode

- Single or Dual lever control

- Adjustable control head detent / friction settings

- “Posi-lock” gear lockout

- Selectable Station Transfer Methods

- Station Lockout Capability

- Adjustable High Idle Settings

- Control Head Keypad Lights Dimmer

- Dual Battery Inputs

- Audible neutral indicator

- “Optional” Gear / Throttle Backup System

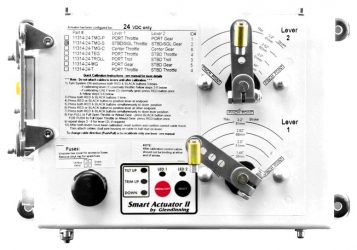

Glendinning Smart Actuator II Control System

The electro-mechanical actuators convert the electronic commands that are generated by the control head into specific positions at the engine gear, throttle and trolling valve. The actuators are housed in rugged, corrosion resistant, aluminum enclosures that are sealed to eliminate problems that may be caused by exposure to the harsh marine environment. The actuator motor drive assembly uses precision ground steel gears and components that are manufactured to very precise tolerances. Combined with a high-frequency pulse width modulation (PWM) input, the actuator is able to resolve a linear position of less that 0.010 inch very smoothly with no “steps”.

- Single or Dual lever control

- Adjustable control head detent / friction settings

- “Posi-lock” gear lockout

- High Idle mode

- Bump mode

- Battery voltage warning indicator

- System diagnostic warning indicator

- Gear positioning indicating lights

- Audible neutral indicator

- Control head keypad light dimmer

- Two button station transfer

System Features & Catalog

- Compact, lightweight construction — suitable for any application

- Compatible with single, dual or multiple engine applications

- CANbus connection to Control Head makes installation easy — up to 6 stations Compatible with Integrated Trim

- Control Head™ — allows integral control of engine drive unit tilt & trim Automatic Synchronization capability

- Easy to follow calibration procedure

- 12 or 24 VDC capability easy