The Tunanator shows her 1970 vintage lines well. She’s maintained her integrity for 30+ years and this was very evident when I cut 8″ oval holes in the bottom of the boat for the new underwater exhaust. The pieces that I removed were laminated out of 3 layers of 3/4″ marine plywood covered with a single layer of fiberglass cloth. The core was totally dry and seemingly brand new. I’m not sure that this type of quality wood construction is easy to find anymore.

I met the owner of the Tunanator, Randy Carpenter, about 3 years ago under an unusual set of circumstances. He had gotten himself into a predicament late on a Sunday afternoon while trying to take his boat through the Channel Islands Harbor to his home in Mandalay Bay..he needed to pass under a bridge. The tide was high this day and Randy, in a hurry to get home, decided that using a saw on his mast was the solution to arriving on time to his dinner date that evening. The following Monday, Randy showed up at my shop with the top five feet of his mast in back of his truck along with all the antennas dangling.

He mentioned that someone told him I could make most anything and showed me a drawing of what he’d like to have fabricated for his boat – – a hydraulically controlled lay-down mast capable of holding a variety of antennas, lights, and a satellite TV/communications dome. To make a long story short, 2 months and $7,000.00 later we became pretty good friends.

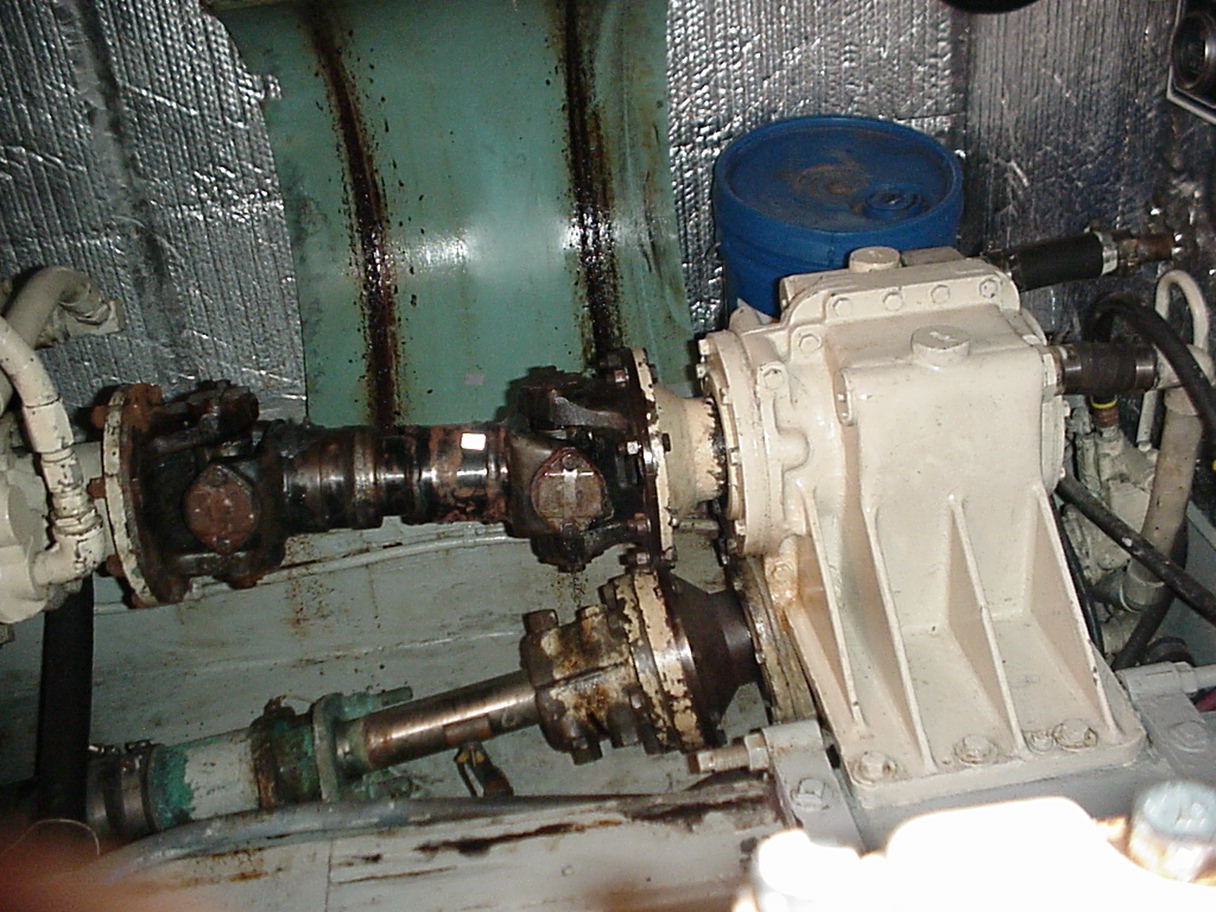

Over the next year or so, I learned quite a bit about his 60 ft Elliot that was built in Southern California in 1970. It was powered with twin Cummins 903’s (450hp V8’s) w/ remote V-drive power-trains. This boat was in pristine condition and, since new, was always kept that way. There had been many upgrades over the years but a modern power-train wasn’t one of them. Randy loved the boat but was not happy with the 9-10 knot cruise. We started discussing what type of performance we could get with some modern higher hp diesels and how we could work around the existing engine room dimensions. Although the engine room was clean, it was quite difficult to work in due to the layout of the present engines, generators, etc. The 903’s were quite large for their power and the boat had two large 15kW Northern Light generators between the main engines making for difficult maintenance for anyone but the skinniest of people.

After much research into the existing performance, propellers, etc. on his boat, I determined that the best choice would be a set of Cummins QSM’s (635hp), a pair of remote-mounted Twin Disc 5114RV remote V-drives, and a pair of 21kW Onan generators. After a thorough redesign of the engine room layout, we were able to accomplish this repower and make the engine room bright, spacious, and much simpler to maintain.

The start of the project consisted of rebuilding the stringers and resetting of larger 2 1/2″ shafts. I was lucky to be able to use the services of local wooden boat building professional, Danny Crave, who allowed us to modify the existing engine beds while improving upon the original high-quality construction. The new main stringers were built/modified with a combination of marine plywood, micro-lam and epoxy.

After about 2 months of woodchips and dust, we applied two to three coats of high-build epoxy primer and finished with a high-gloss 2-part polyurethane. The new Onan 21KW’s were installed cross-wise behind the new engines, completely freeing-up the space through the middle of the engine room.

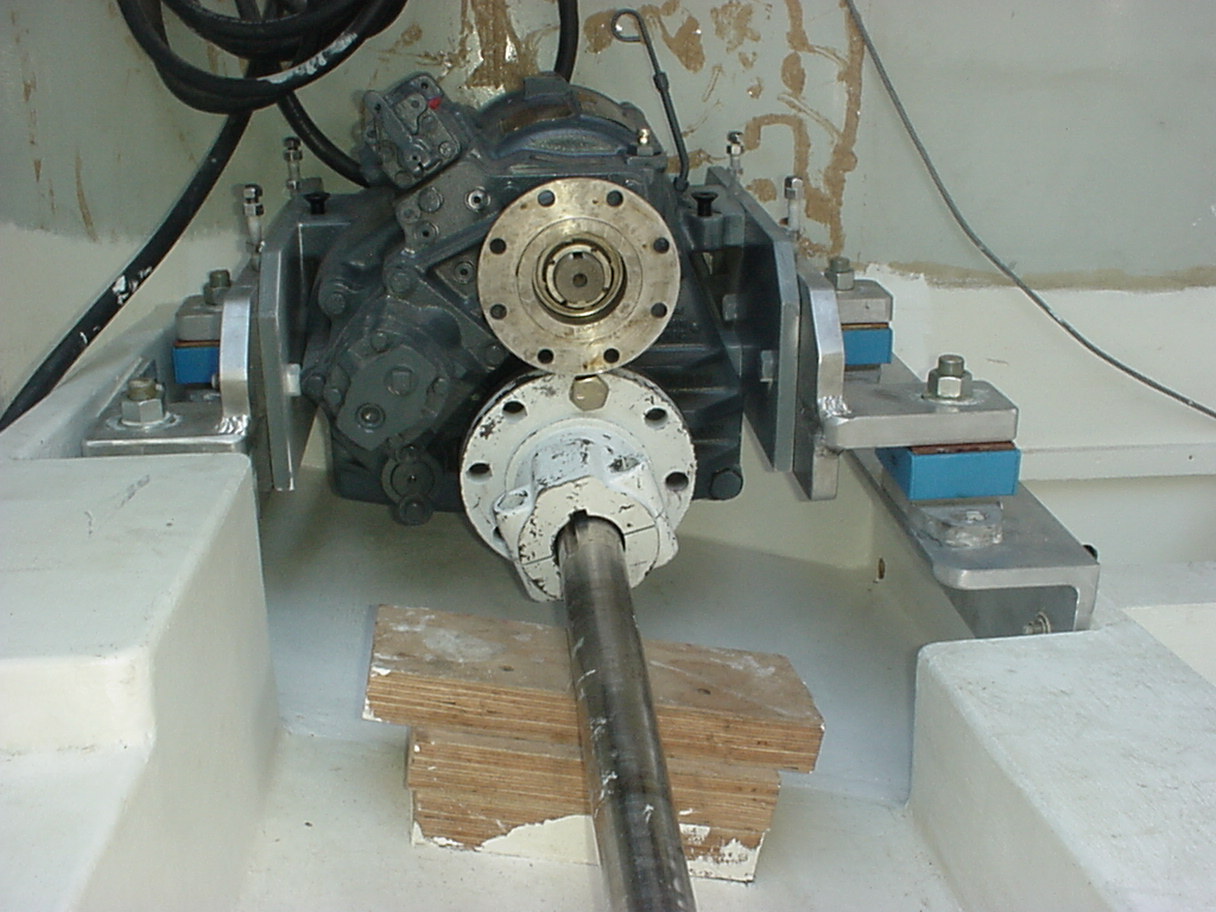

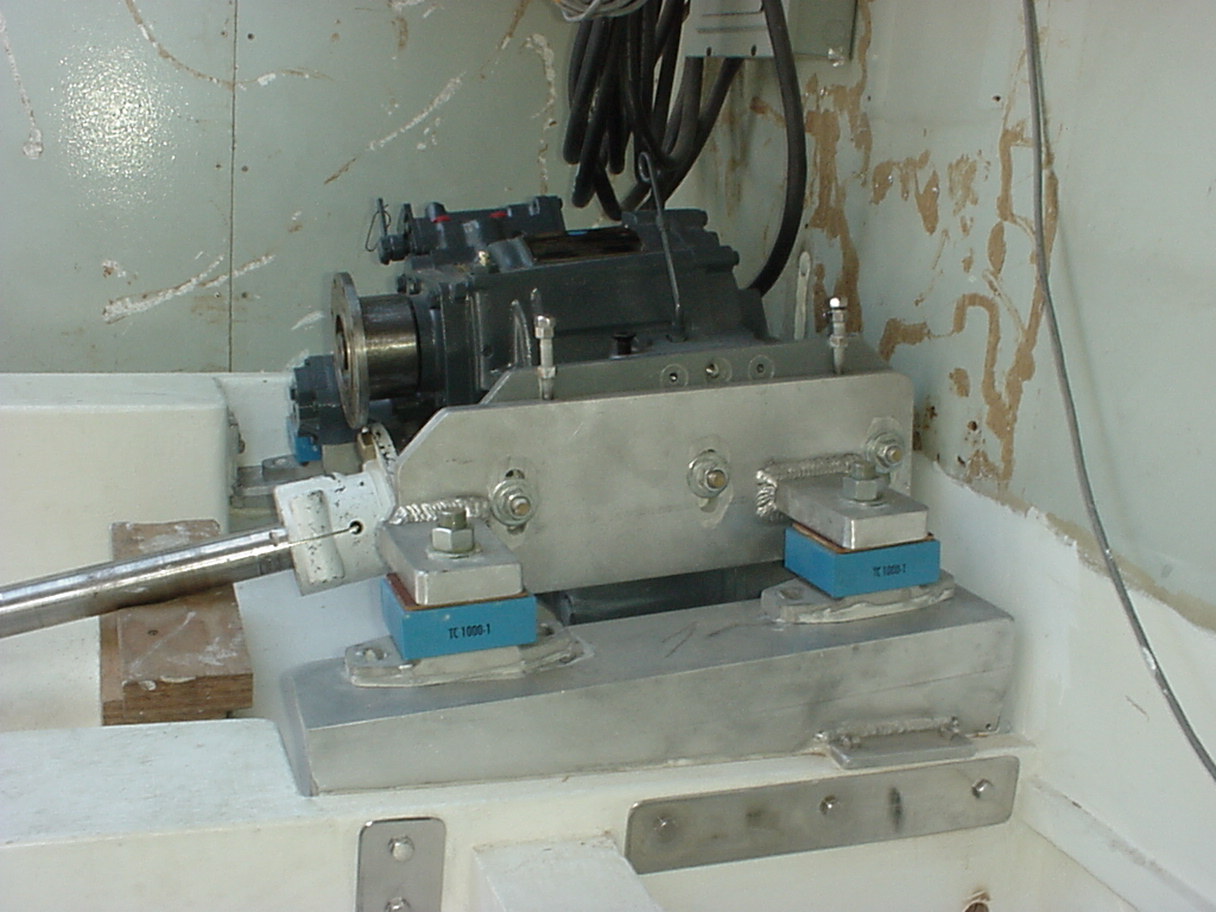

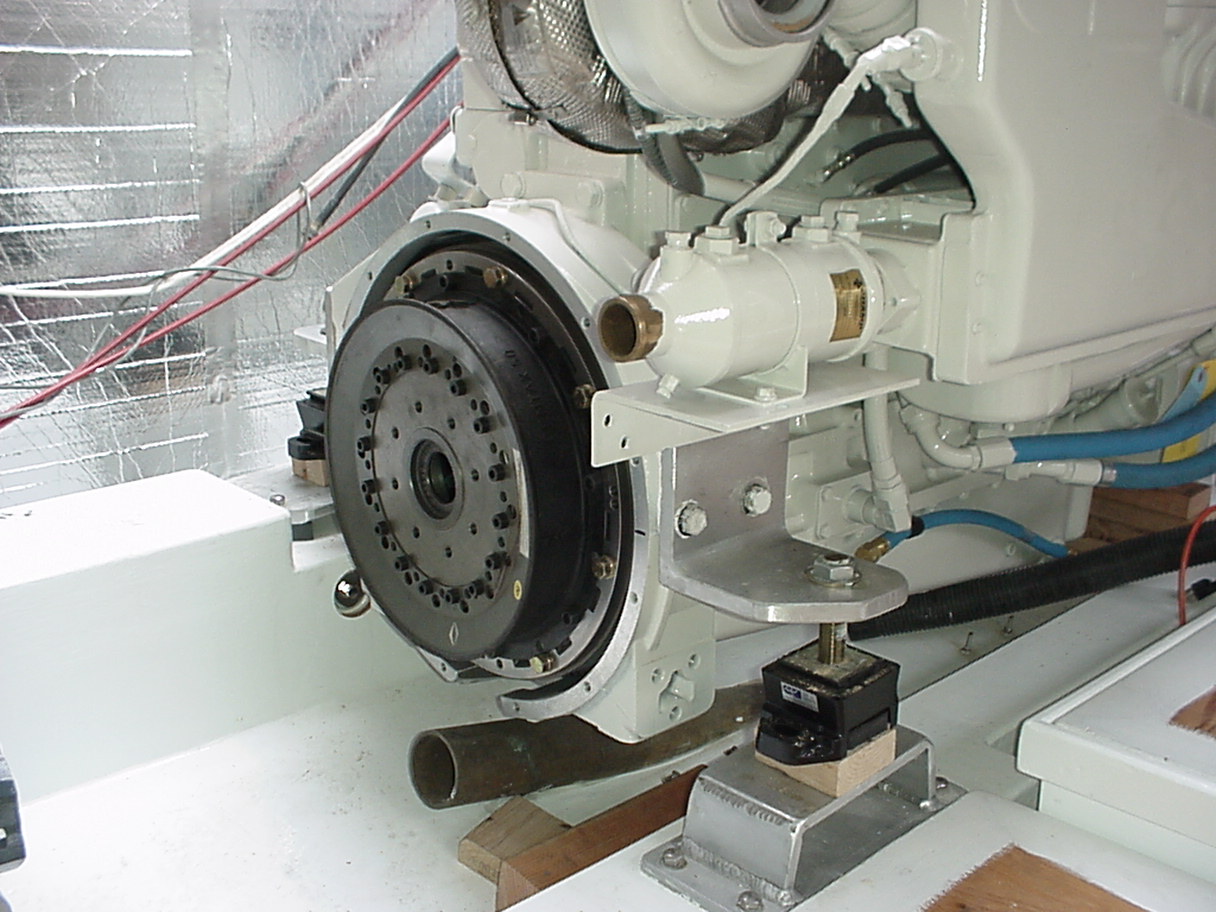

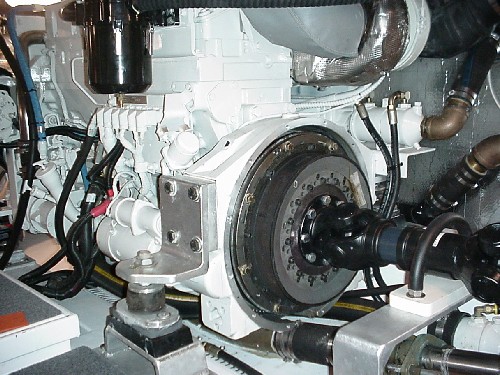

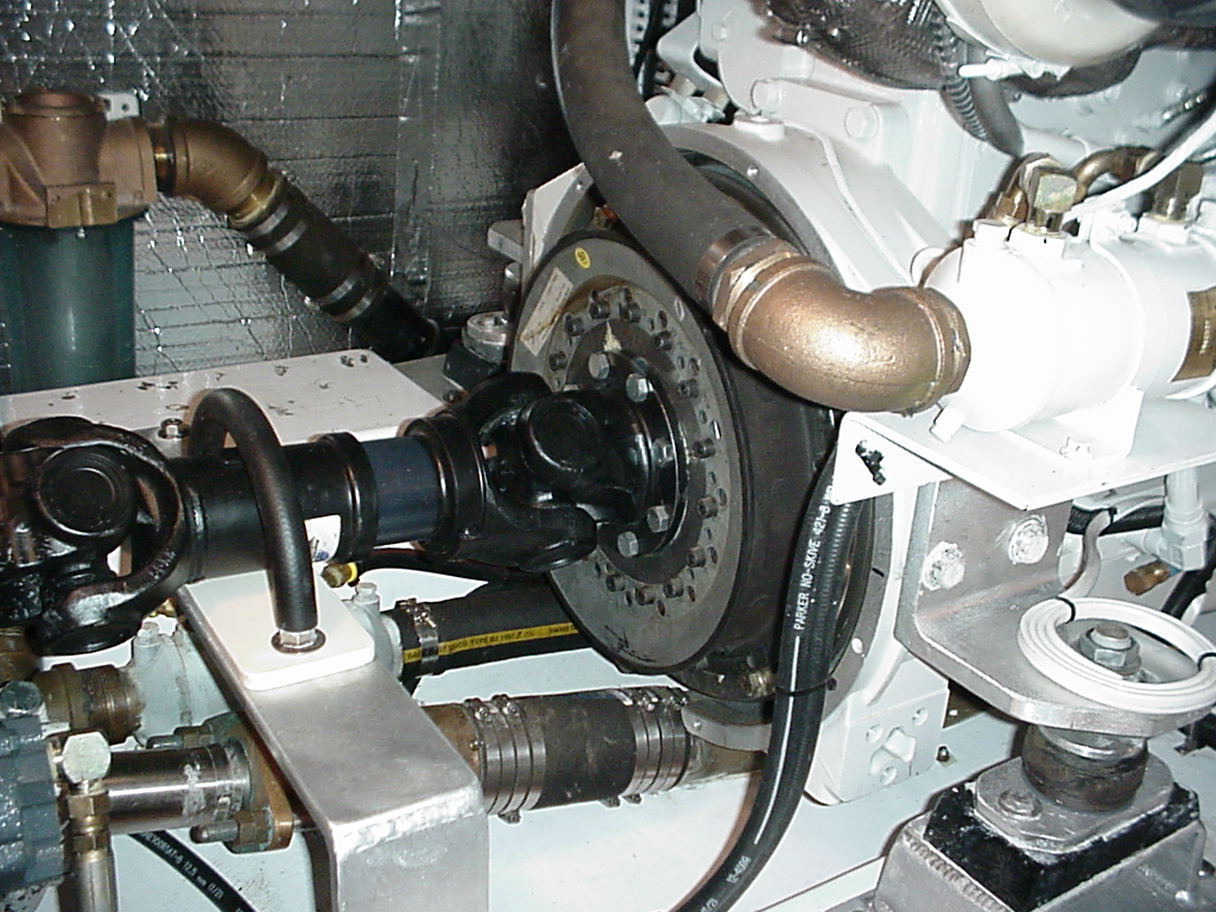

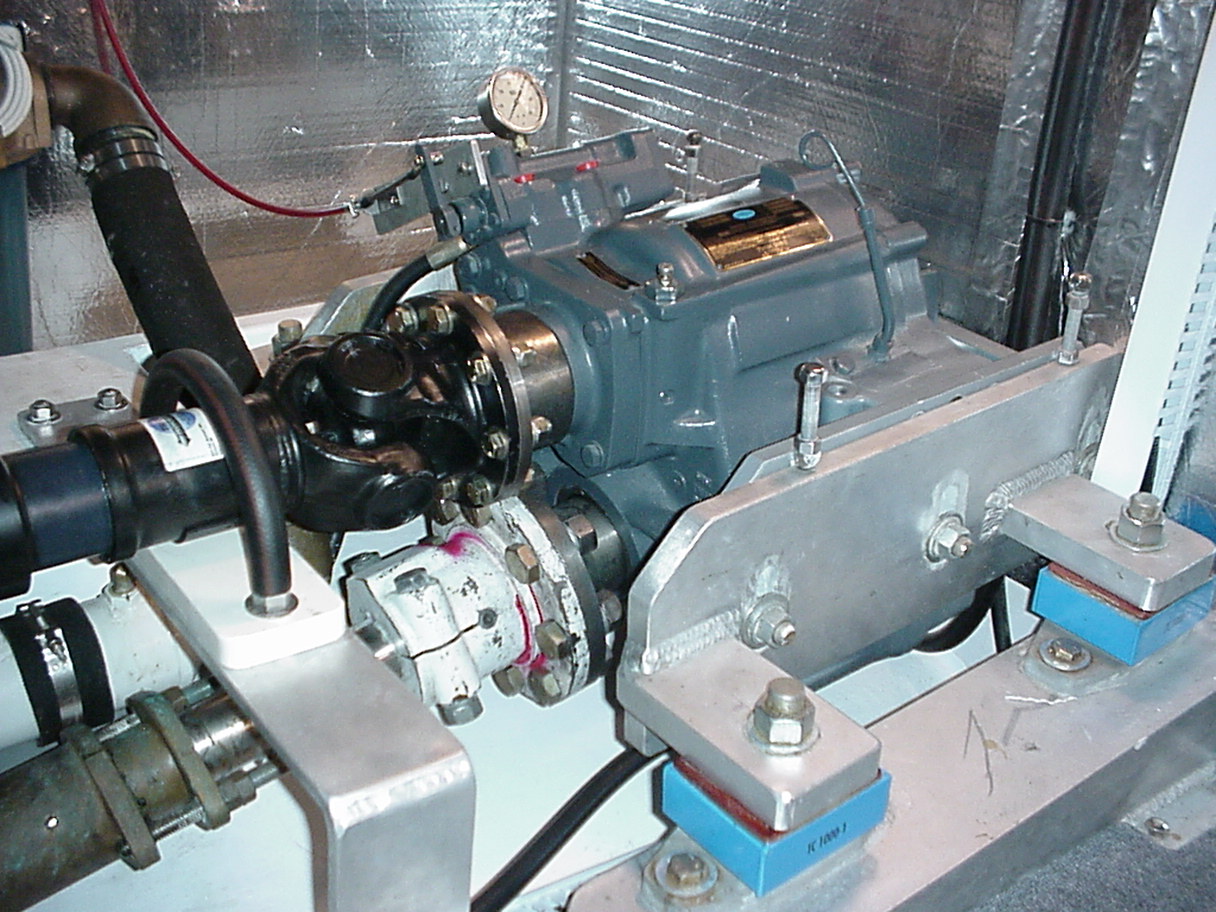

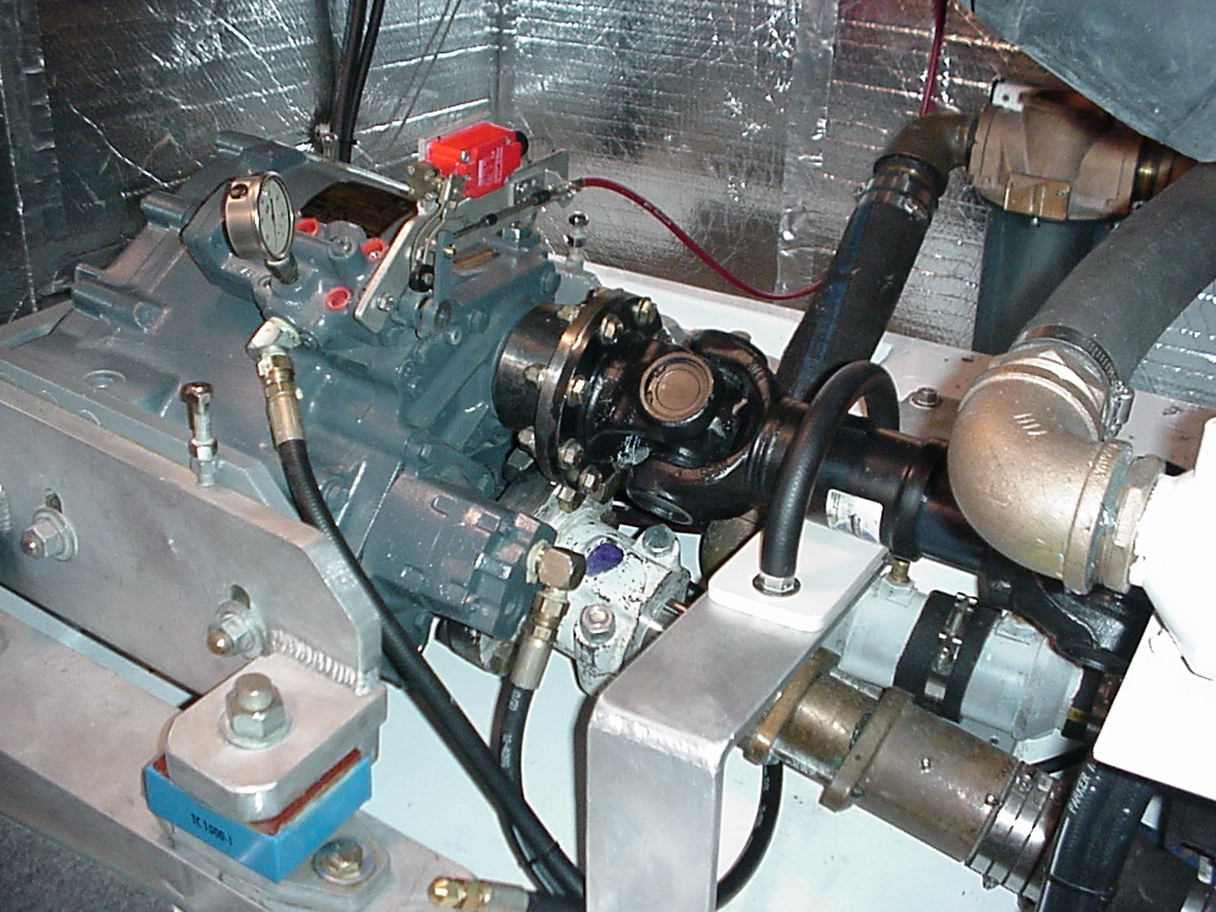

Port and starboard V-drives went in before the engines were put in place. Because they are remote, the mounting is paramount to this project being successful. I think of a remote V-drive not only as the transmission, but also as a large thrust-carrying bearing block. I design mounts that are not only substantial, but are also easily adjusted/aligned while keeping the V-drive fully isolated from the boat thru resilient isolation mounts. In this case, I used Clark isolators with thrust caps that allow for 100% isolation and yet have the slight flexibility needed to follow the imperfections of movement in all power-trains. You might think of a remote V-drive as a large oil-cooled heavy duty thrust bearing that is “literally” pushing the boat. The use of heavy aluminum fabrications (3/4 – 1 ½” thickness) is evident and is my material of choice.

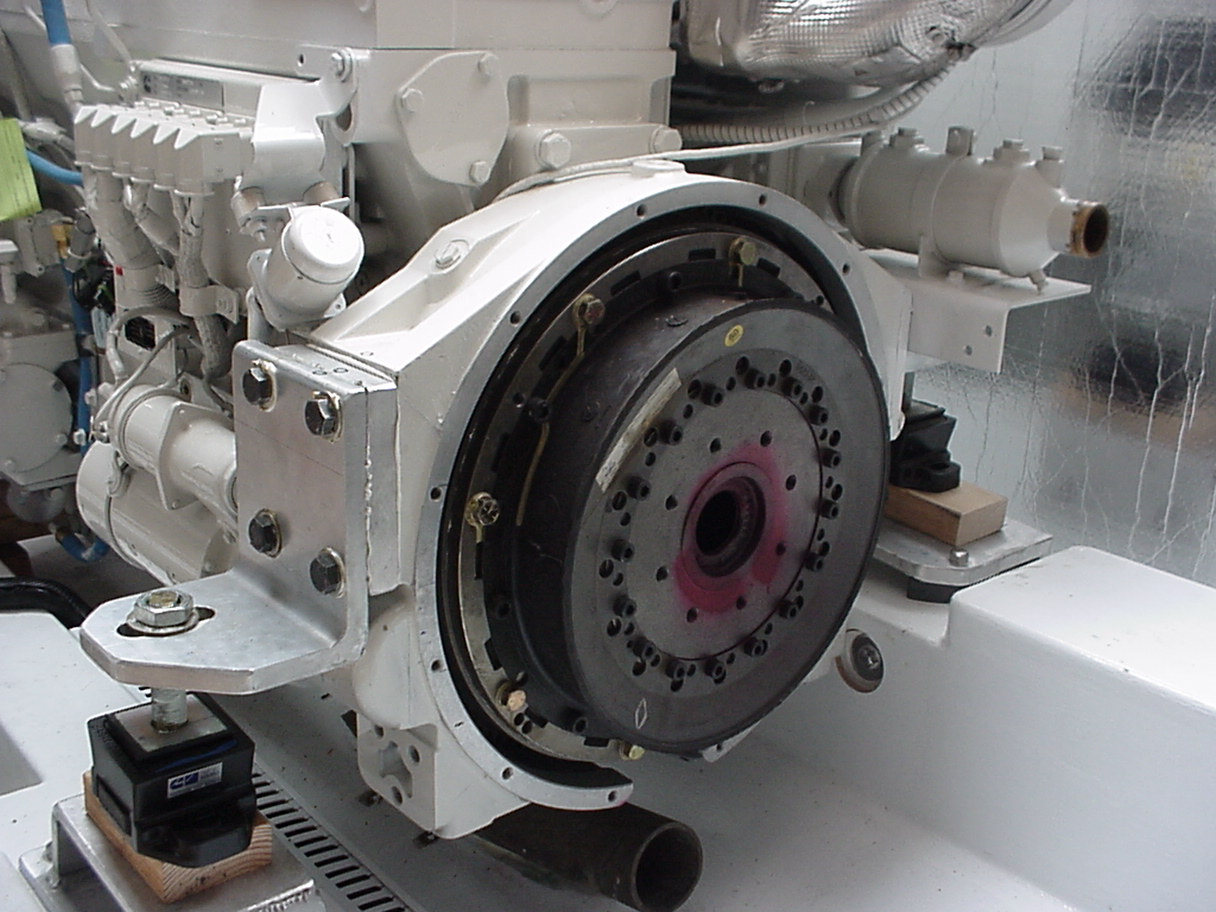

The sky may have been gray, but this day was happy as we were finally lifting the QSM-11’s into the well prepared engine room. After a couple of months of hard work and doing as much as possible BEFORE we set the engines, the lifting and setting of both engines only took about 30 minutes.

No surprises as the all the planning paid off with a near perfect fit. As the critical alignment is between the V-drive and the propeller shaft, mounting and alignment of the engines thru a GWB U-Joint shaft was going to be easy. A sharp eye will notice the removal of a piece in the lower part of the SAE #1 bell housing. This was going to let the engine to sit about 2″ lower and would allow us to keep the U-joint angle to under 3 degrees each in a “W” arrangement. We knew before hand that with the short drive line that the closest point of the engine touching something was going to be the bronze shat log coming thru the bottom on the boat. Over the next couple of days, we moved the engines into their final resting spot.

With the engines set in their final resting spots, we installed the very stout Centa self-supported carden shaft torsional couplings and the extra heavy duty GWG drive lines. Although I typically try to use Spicer U-joint cardan shafts, in this case I chose GWB (from Germany) as the rating for the same physical size drive line is more that 200% higher than equal sized Spicers. With 635HP at 2300 RPM and mid-range torque capability of approaching 1800 Ft lbs, I didn’t even want to think about a failure in this component. Notice the 5/8″ diameter S.S. U-Bolt safety containment loop around the driveline. Just in case!!!!

I also used custom isolators as all we had to do was hold the engine down…NO THRUST.. With soft mounts, the lineal vibration and noise transmission to the hull is kept to an absolute minimum.

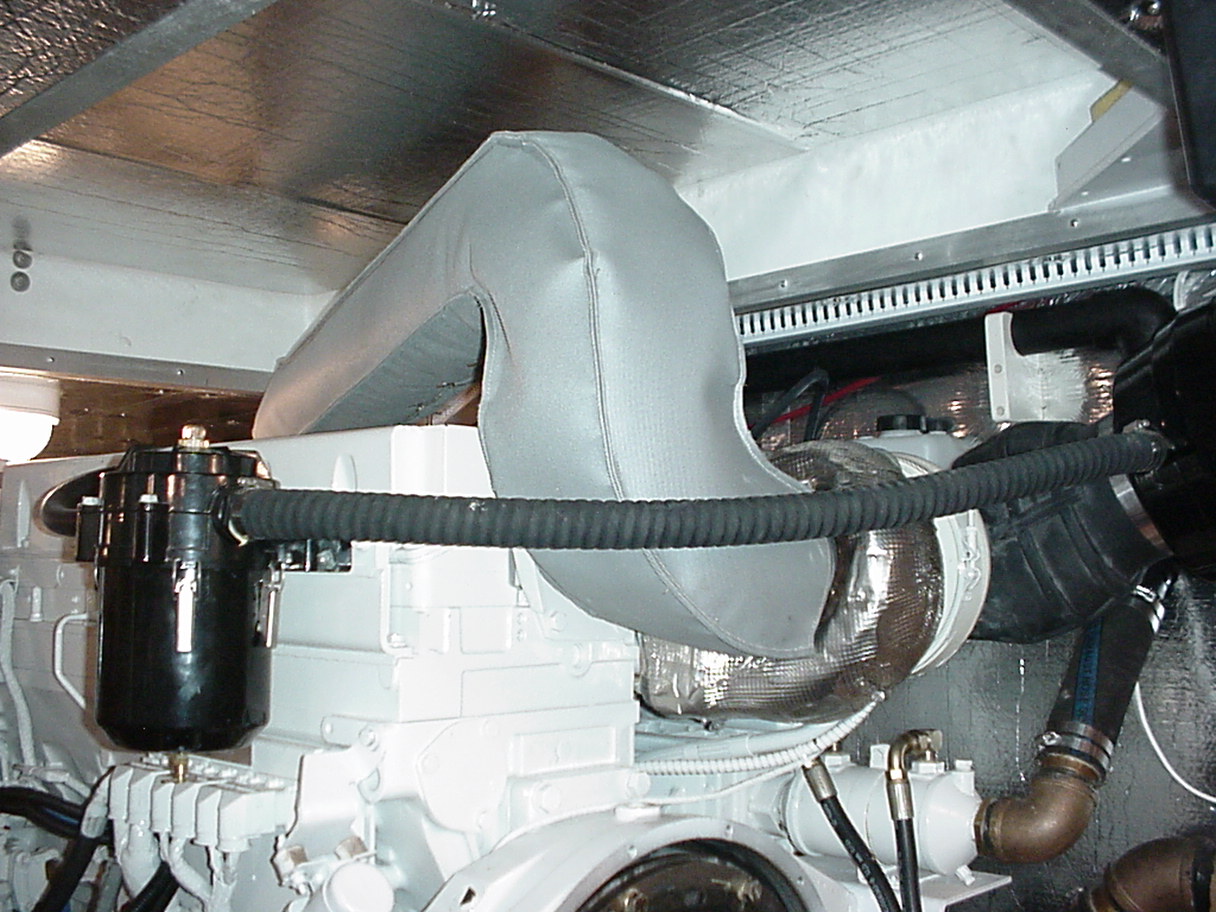

Besides mounting of the engines comes all of the sub-systems. Port and Starboard exhausts were a challenge as not only did we want to keep access very good around the engines, we had to design a quality system that was very quiet, fit the boat, and met all of the restriction and safety requirements from Cummins. We knew from the beginning that we wanted underwater outlets, but with the final outlets being very close to the stern, we opted for custom low restriction lift mufflers between the risers and the underwater outlets. As long as we did the right calculations and incorporated much from our past experience, I felt comfortable that we could accomplish our goals.

SUPER QUIET, LOW RESTRICTION, GOOD ACCESS AND SERVICEABILITY, SAFE w/ LONG TERM RELIABILITY….

These pics show what we came up with and as far as meeting our goals???…Sounds like water rushing over a waterfall, and above 12K’s or so, the exhaust pressure goes from a maximum of 20″ Hg (about 11-12K’s) to a vacuum at 16+ k’s….

Better than we hoped for….

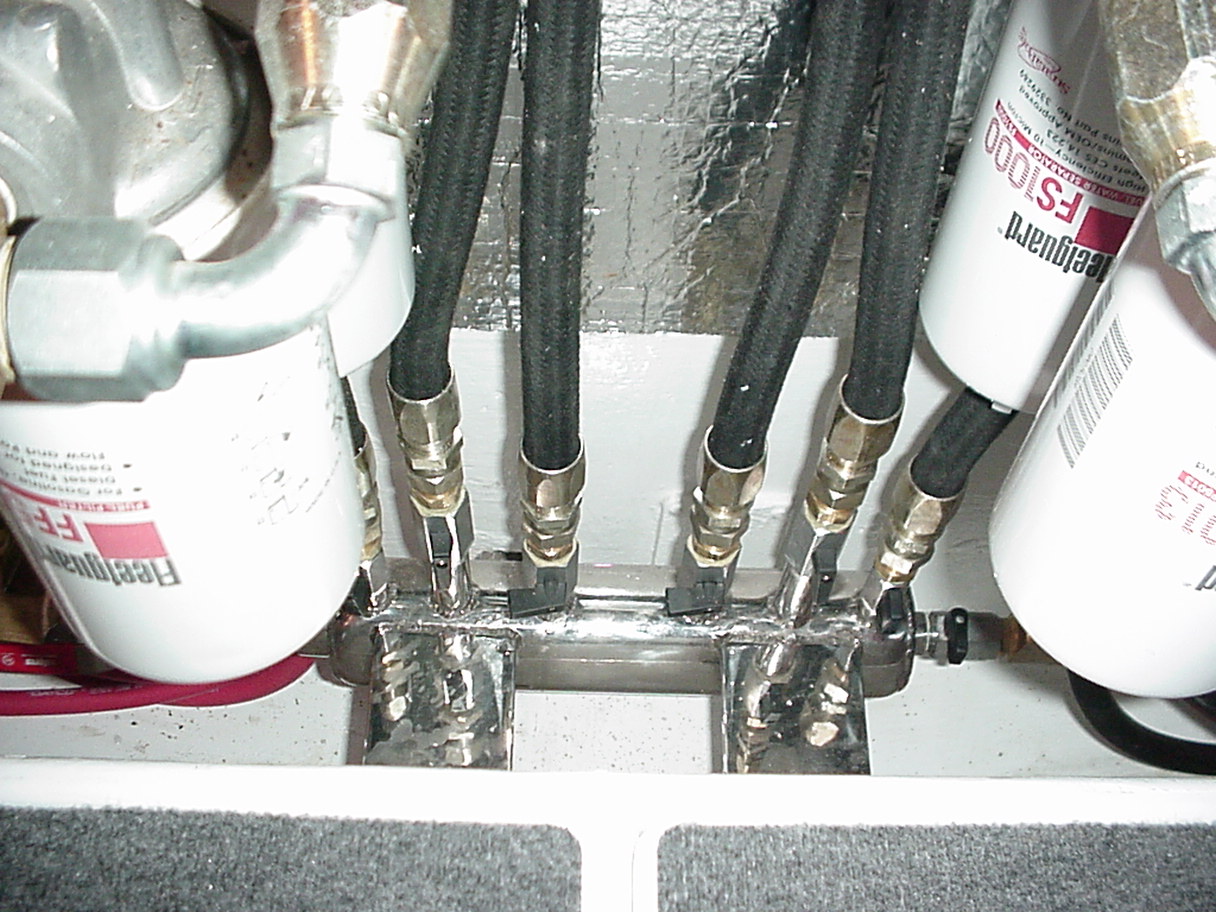

Fuel management is always a component of a well thought out boat.. I can’t tell you how many smaller boats I’ve seen where “fuel management” seemed like a after thought.. I still see new boats that the builder is planning(?) to use fuel to “trim” the boat???? Talk about stupid. Concrete is much cheaper and takes up much less space should the builder “blow it” on weight distribution. Back about 30 years ago when this boat was built, Elliott had a vision and in the case of his design for fuel tanks, he was cleaver. Mounted the tanks so ALL of the fuel can be used, had great access to ALL of the fittings and he installed first class sight gages so even a dummy can figure out what’s going on. I was able to make both P & S tanks act as one and built a custom manifold at the back on the engine room that had (1) 1 /1/4″ AQIP type fuel line feeding it via gravity.. From there it was easy to feed both engines and both generators..Even put in a 5th output for pumping fuel to a friend in need or ????

I use a special epoxy on ALL of the threaded fittings when I assemble a complex fuel manifold….ZERO chances of even a slight “sweat” of diesel. Don’t want to spoil a clean engine room with any #2 stuff where it’s not wanted….Although I didn’t think it was necessary, the owner wanted “doubles” on the main engines so he could switch while running.

This is a typical Multi-Stage system that uses a 30 mic “bulk separator” for the first stage, and then a 10 mic fuel water separator/fuel polisher with proprietary filter media made for Cummins most the demanding applications. I have been using this same system for about 10 years in commercial applications with annual fuel consumption well above 10,000 gallons per yr/per engine. Very reliable, predictable, and easy to maintain………

As with any repower, other systems have to be installed con-currently along with the big-ticket items. The picture here shows one of the custom lift mufflers for the generators, the 8″ “thru the bottom” outlet in the lazarette for the main engine, and a very nice, but simple dash that one of the owners friends put together.

All done except for the launch and much awaited seatrial. With 2:1 gears, 2 1/2″ shafts, 1370 HP and 32x 28″ wheels, we were looking for a 15K+ cruise fully loaded for bear, and a 18-20K top end on this 90,000 lb, 30+ year old plywood boat. Along with that, the owned literally demanded that this boat be quiet and smooth like no other in this size/HP range… Did we do it???…. Well, Randy and I are still the best of friends, and he’s still buying more “gingerbread” for the boat. To me, that says it all..

As for performance and what our goals were, after a few typical sea trial glitches and some prop tuning, the boat now cruised fully loaded at not less than 3 knots above the old top-speed of 13 knots, and was substantially quieter, smoother, and noticeably more economical at the lower speeds below 10 knots. The job turned out to be more complex and expensive than we anticipated but many other upgrades to the boat were undertaken during the repower. The boat has now been fishing hard for over a year and the new powertrain has proven to be 110%.

The QSM’s have performed flawlessly (over 700 hours at this writing) and are the cleanest running diesels I have yet to experience. And as an added plus for this boat, Randy was able to hook up with a great full time Captain, “Dan Block”, who has proven to be a wonderful compliment to the on-going operation of this vessel.