It’s not often that you run into the opportunity to have someone work with your past experiences and efforts and raise them to a new level. In this repower project, I was lucky enough to find a guy who is very special and had the talent and motivation to do just that. That’s what this article is all about – A Very Special 25 ft. Bertram.

Jim Graham, the owner of the Bertram, decided he would do some research on his upcoming project and found, what I think, is the best place around to ask a few questions. The thread was short and but to the point, but got his attention. He contacted Seaboard after a few postings and the project went forward from there.

Jim turned out to be one of the most talented persons I have ever had the opportunity to work with, as his finished work is well above what the pics can do justice too. As you can see from the pictures, this project went well beyond what a typical repower would be and, to me, it should be called a “new boat” that was literally built from the bare hull up.

After Jim and I came to a general understanding of what needed to be done to accomplish his goals, we proceeded from there. Jim “gutted” the boat all the way down, close to a bare hull and then started the “resurrection” process.

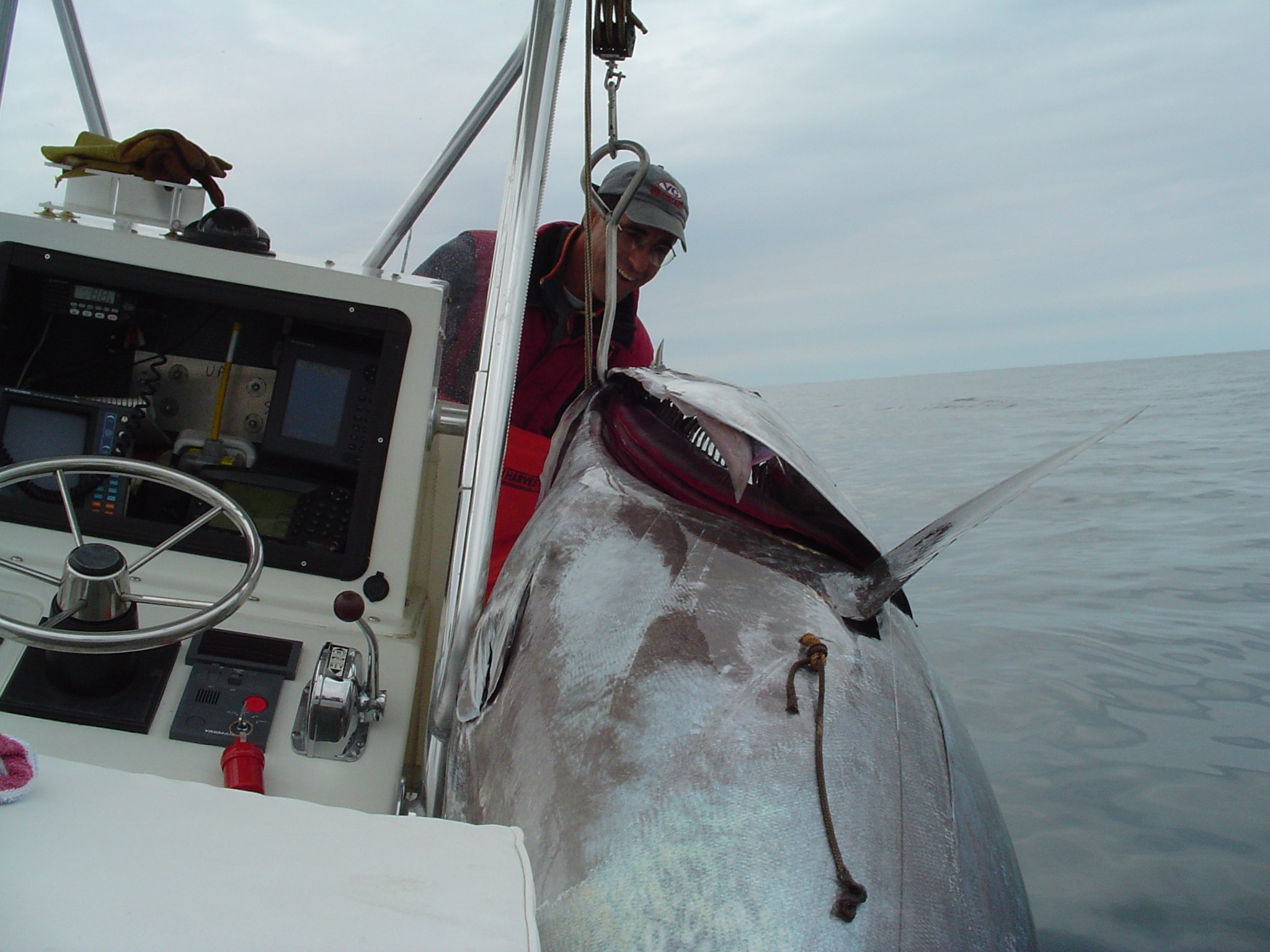

I put together a few drawings and added a lot of individual attention to some initial construction details on how to get started. We decided with the engineering of the stringers and placement of the fuel tanks in relation to the engine/boat. The key here was to come up with a small boat that would be in close to “perfect trim” regardless of the variable weights-these, being fuel, bait, & and payload (like a 400 Lb Giant Bluefin or 500 lbs of assorted albacore / tuna.

I think these two pics say it all about Jim’s BIG FISH and “little boats”

Smaller vessels are very weight and trim sensitive and experience has shown me that you NEVER rely on the variable weight of fuel to balance a boat, although, to this date, many builders and owners do otherwise or seem to think that is the only way to balance a vessel… WRONG !!!! I’ll say it again so it sinks in, “WRONG !!”

With any smaller vessel, one needs to design the vessel so IT IS IN (reasonable) TRIM, regardless of whether it is full of fuel, low on fuel, heavy on fish, or NO fish-a very simplistic engineering accomplishment if you give it a few minutes of thought (as long as you are not stuck on a couch in the frame of mind that says “it’s been done that way for 40 years, why change”………… ).

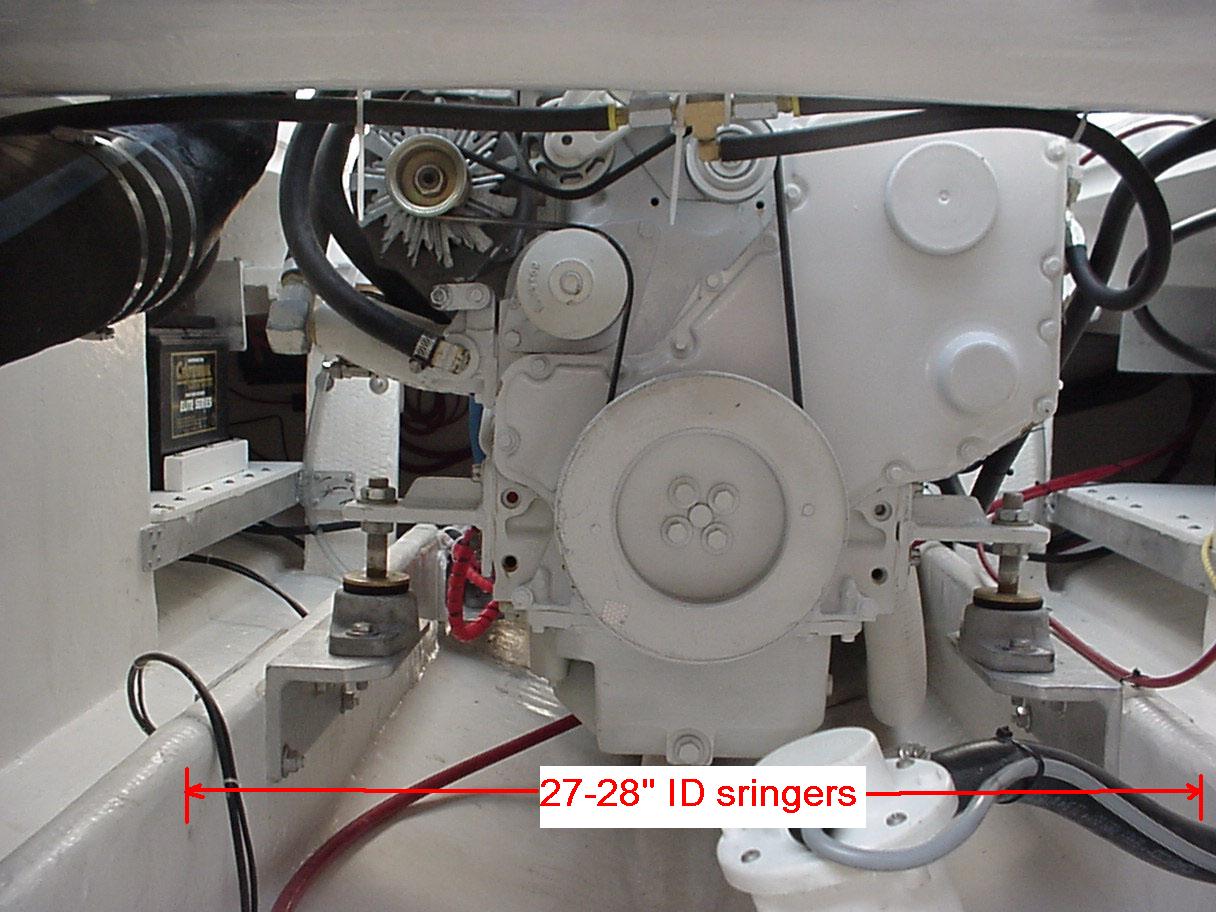

New stringer and bulkhead construction-Iso-resins & Micro-Lam make for the “best of the best” from both the practical and engineering standpoint in this type of re-construction work. A very rigid “H” section from the fwd engine room bulkhead all the way to the transom is very important to maintain good engine to prop shaft alignment under the worse conditions.

The above (modified) line drawing from the original builder was used to figure out the right placement of the engine, shaft angles, prop size and gear ratio, and fuel tank placement. Actually, quite simple when you really understand how vessels of this size range operate in real world conditions. Put this drawing together with the owner goals, the weight of the engine and drive train, the variable weights of the fuel & payload, and with some past experience, the placement of the equipment is a given for the best overall vessel performance and handling. When these simple calcs were done, the only feasible and practical powertrain that would give “commercial ruggedness” to the vessel was a conventional shaft, prop and rudder, a proven diesel engine and properly installed V-Drive.

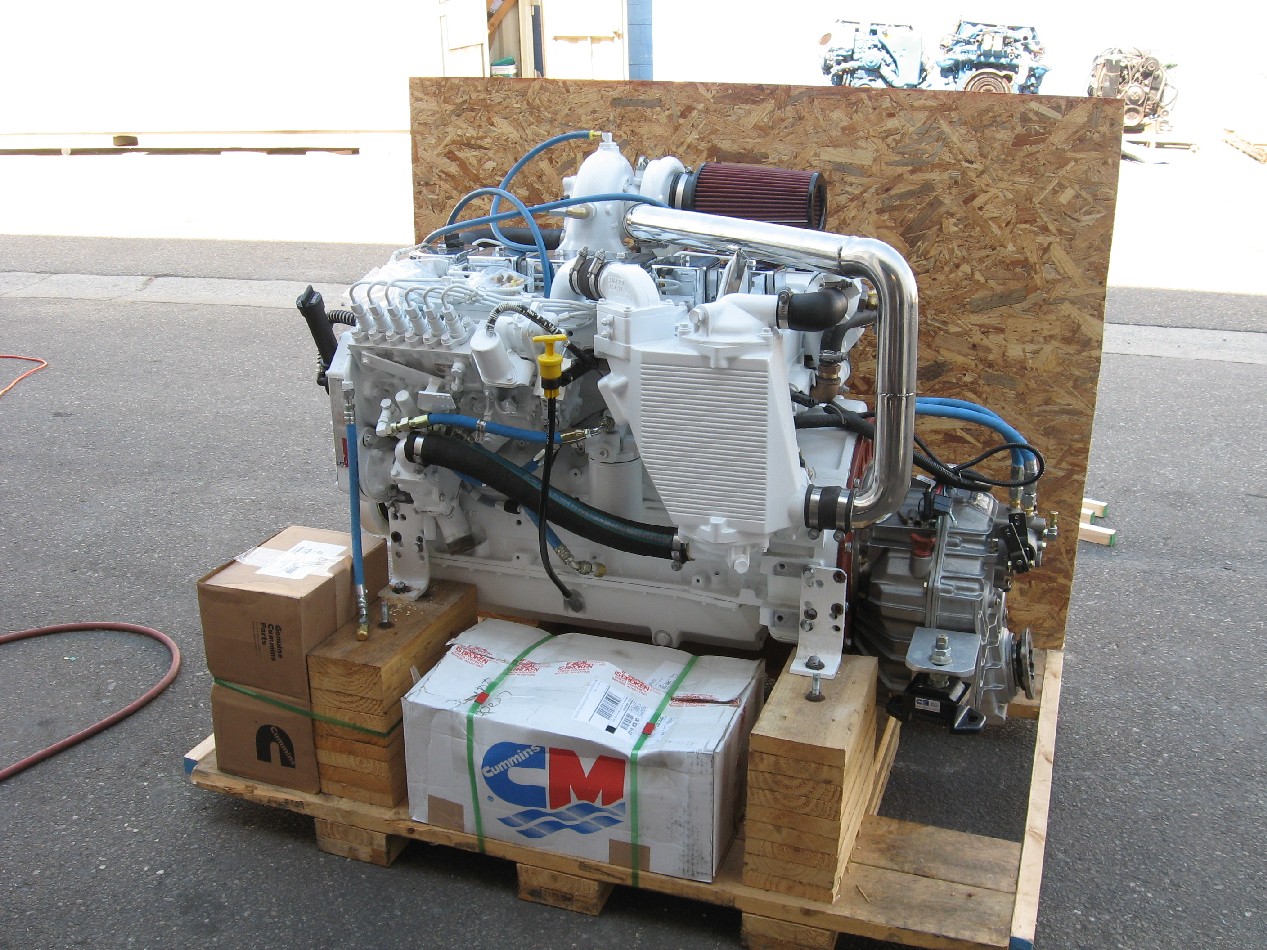

From there the choice was simple – A Cummins 330B w/ a custom configured High-mount turbo, and a ZF63IV w/ a 1.5:1 ratio and propping that would allow the 330B to easily hit rated ++ RPM at WOT under the worst conditions. This engine trans combo has proven itself to me for over 15 years as a rugged and simple set-up that will stand up to the rigors of the marine environment and is simple and inexpensive to maintain.

My original calcs based on my finished “projected weight” called for 19-20″ of prop diameter, pitch so to get not less than 2900 RPM at WOT, 1.5″ shafting, and the engine V-drive placement to allow less than a 12 degree shaft angle. The base layout is below and is a general overview of a close-coupled Cummins High Mount set up we have been using for about 15 years now. We consider this “base layout” a good starting point for planning purposes and can be easily adjusted for each individual vessel.

Progress on the messy part (fiberglass reconstruction) went forward over the next few months as planned. Jim is very fastidious in his work and cuts no corners. With East Coast 2006 winter approaching, I think the goal was to get it all painted and ready for a winter sleep, and then start up again after the thaw in 2007.

Progress in the first 4-6 months before winter set-in

My past experience with projects like this says the first Champagne bottle needs to be broken when the fiberglass work, grinding, sanding, fairing, and painting is done. The Launching is anti-climatic in comparison.

It was now getting time for the engine trans package. We put all together per spec, tested the pkg at the shop to be sure all was 100%, and shipped it to Jim in Spring of 06.

Before the final painting was done (boot stripe, etc), Jim wanted to be absolutely sure of the vessel’s static trim. So, it was to the harbor and a trial setting of the engine. You can’t really blame Jim, as he was relying on our calcs and he had already received a different repower weight distribution scenario from the builder that said that this would not be kosher. The pictures below put all to rest as the boat sat exactly as planned with or without the variable weight of the fuel.

Jim now felt much better, he marked the boot stripe, and it was back to the paint booth…

By Nov 06 the vessel was ready for a winter lay-up indoors for final painting and the most fun part of the project-Outfitting the engine package and all of the goodies to complete the vessel.

By the start of the spring thaw (Feb 07), Jim’s new puppy emerged with a totally new look… Now all of his patience and work was coming together.

Between Feb 07 and the upcoming summer, and with the time Jim had to devote to the project, the vessel was 95% finished with completion of the power train, steering system, electrical system, fuel system, misc engine sub-systems, electronics and all of that extra gingerbread that you need to catch one of those Giant Bluefin Tuna.

By mid-summer 2007, Jim was finally near enough that he could start getting some pay-back.

In the water in June 07 with some testing to be sure all is right before he starts chasing those tuna… The vessel sat perfectly and could easily handle all of the additional weight forward including anchor gear, a 150 gallon bait tank, and all the creature comforts that were still missing. With the exhaust exit under water, and with the inherent safety of the high-mount turbo and mixer about 18″ above the waterline, no muffler was needed.

By Sept, the vessel was up to about 99% outfitted and it was time for some fun.

Yum Yum is all I can say when they are this fresh – Cooking not even needed!!

Although Jim has a list of things to do this coming winter ( find me a vessel with this much attention to detail that is ever finished and I’ll show you an owner who’d rather play golf than fish on the weekends), he has the next few months to play.

Per Jim’s own words and how this project went forward, and why WIDGEON will occupy much of Jim’s time this winter…

“Most people would put me in the “pain in the ass” category instead of talented. If you were to watch this whole thing progress, it’s the measure twice cut once adage that fit here. Only I measured 6-7 times, making sure all options were exhausted before making a final decision. Also very stubborn.

As with any project it’s never done. As I mentioned earlier, there is quite a list of things to do this winter, but as you also mentioned, paying close attention to trim. It is the paramount concern in having a good boat. Trim wet or dry. There is a 150 gal bait well forward if the engine. This is plumbed not only with a pump in and out, but holes in the boat bottom with plugs and scoops to fill and empty. This allows me to keep bait overnight without pumping. All this weight does not affect trim either full or empty. It’s nice to have that ballast in a head sea. Also no need for trim tabs. Nice clean transom. Need to figure out the right covers for the scuppers, backing down gets a bit tense.

Bought a case of WD-40 and keep everything wet. So much so there are drippings in my clean bilge. Aargh!

As the winter approaches there will be lots more questions.

The performance is plenty good for me. Not sure of accurate fuel consumption yet, the shape of the tanks renders a fuel gauge useless. Need to get a Floscan system this winter.

I am still topping out at 2800 on the dot. That’s with 135 gals of fuel on board.

The manual says at 2200 the burn is about 8.4/hr.

Prop is 20 X23 four blade with a slight cup.

At 2200 GPS says 22.5 kts depending on sea conditions

2300 almost 24 kts

2800-30kts

Couldn’t be happier with this setup. Especially the industrial strength Cummins.

My Current Thoughts:

Now that most of the dust has finally settled, I am recommending to Jim that he buy a new prop as I am sure the 4 blade is dragging him down with unneeded blade area as WIDGEON is lighter that I thought it would be. I’d go with a “ZF Faster” or “Michigan DJX” Nibral prop, class 1 or better, 19 x 24 – 3 blade with a #4 cup. I would expect Jim to make 32+ knots and allow the engine to reach an extra 50-75 RPM. Fuel consumption should rise to about 2.8~3 KPG at 22-23 knots……

My hat is off to Jim and his “pain in the ass” attitude as I just don’t think it could get much better, although our motto at the shop is that “there is always room for improvement”. Jim didn’t leave any in my opinion……