Description

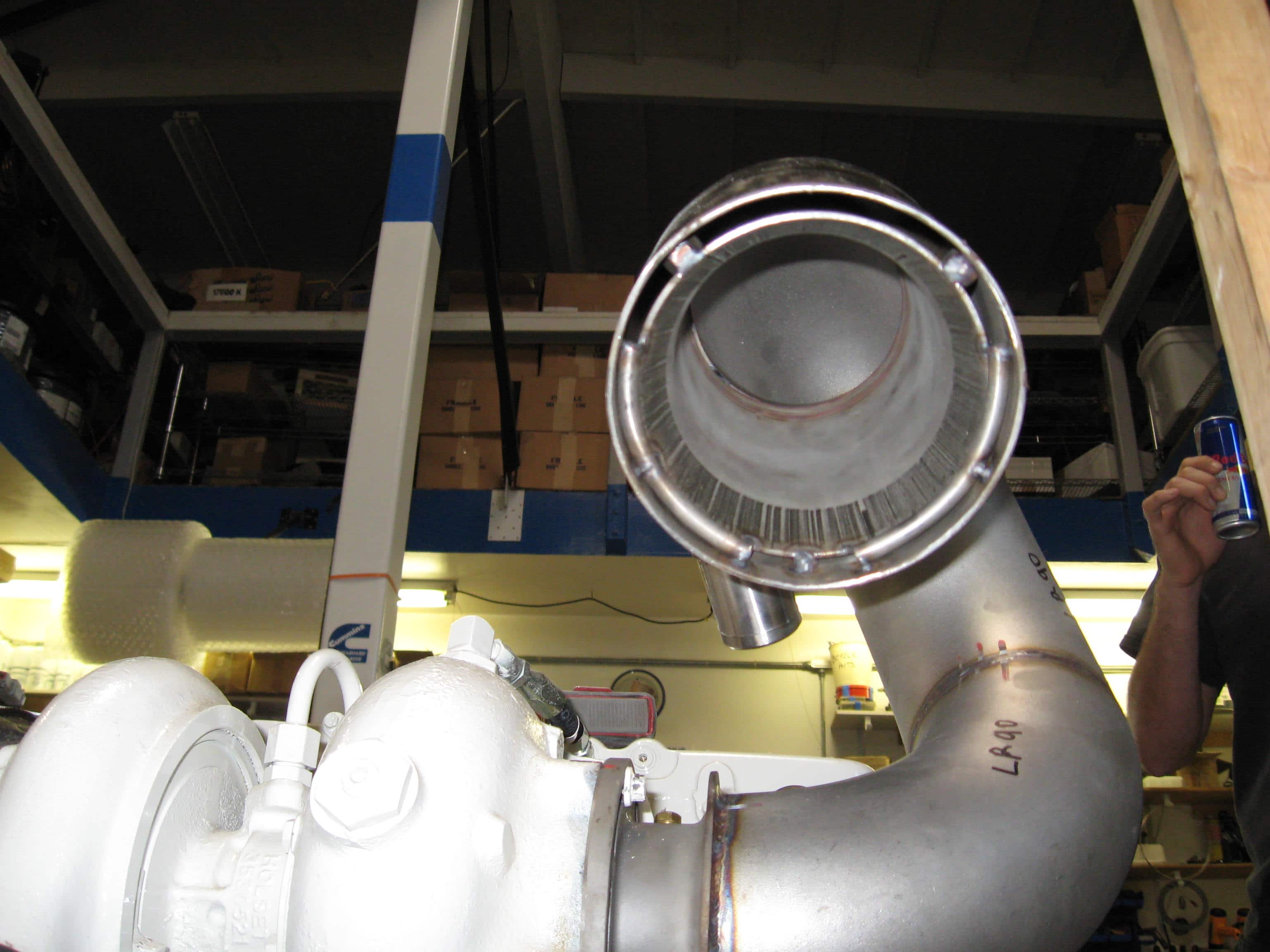

Our unique Mixer spray ring design———-Our design was came about close to 25 yrs ago and is still unique to this day. Instead of a typical symmetrically drilled spray ring which always causes “hot spots” in the hose, especially at lower speeds, we developed custom tooling and use a flared spray ring that the makes the inlet water fill the mixer at all speeds and makes close to 75% of the water exit the mixer at the top and fall thru the hot exhaust gases in the exhaust. Also, because of this design, many times we can use 5” mixers in place of 6” mixers on engines up to 400 HP between the mixer and the muffler, even if it is spec-ed at 6”.

Seaboard Marine has a proven 20 plus year track record of engineering and fabricating custom marine exhaust systems for all types of marine diesel applications. Our highly popular dry riser to wet exhaust system has become the new standard for small to medium diesels up to 750HP, and we’ve solved a lot of the problems we see with other approaches to marine exhaust. Over the years, we have continually refined every aspect of the engineering and fabrication process, as well as sourcing the best materials, so that we can offer the best marine exhaust systems on the market.

What’s wrong with the stock exhaust elbow or riser?

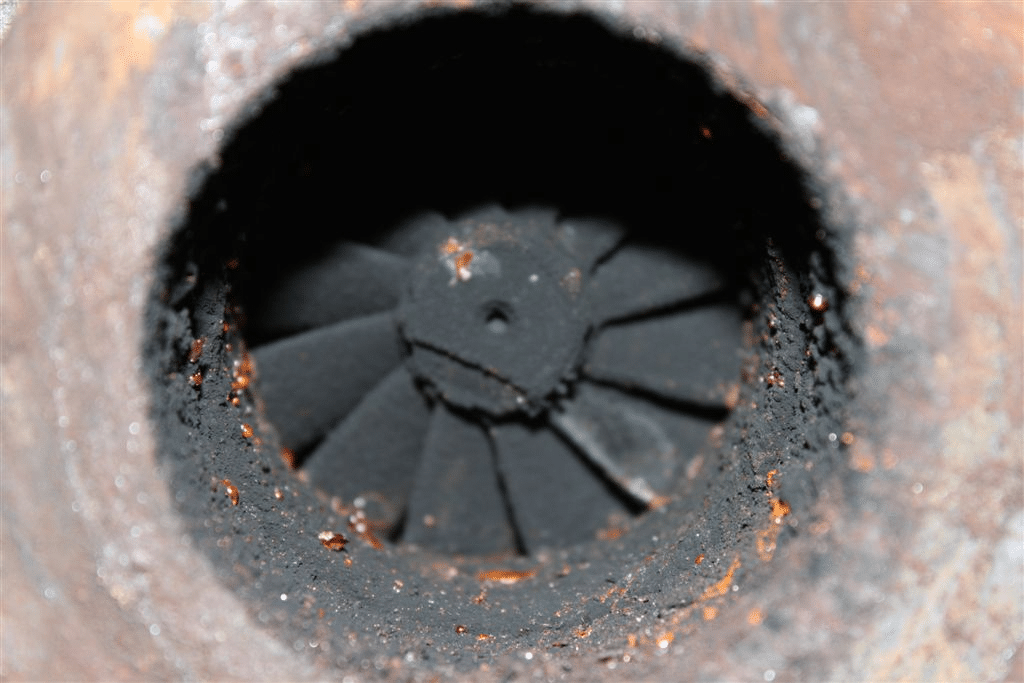

You would think the engineers who designed the engine could build a decent exhaust, but in fact its nearly impossible to make an effective cookie cutter exhaust system for a marine application. The standard approach is a wet mixing elbow or wet riser. These exhaust designs with few exceptions are “doomed to fail,” as they are often made of relatively thin material and inherently hold raw water within inches of your precious turbo. The only thing keeping gravity from introducing that water into your turbo is a thin piece of steel that is known to corrode and leak. It’s a simple question of what will last longer, that thin piece of metal or Gravity? While it may seem unfathomable that such a pervasive issue could plague the industry, if you look at it from the point of view of the engineer who designed the engine, the question is simply what will last longer, that thin piece of metal or the warranty? To that end, they have designed a perfectly adequate exhaust.

What are the advantages of a custom dry riser?

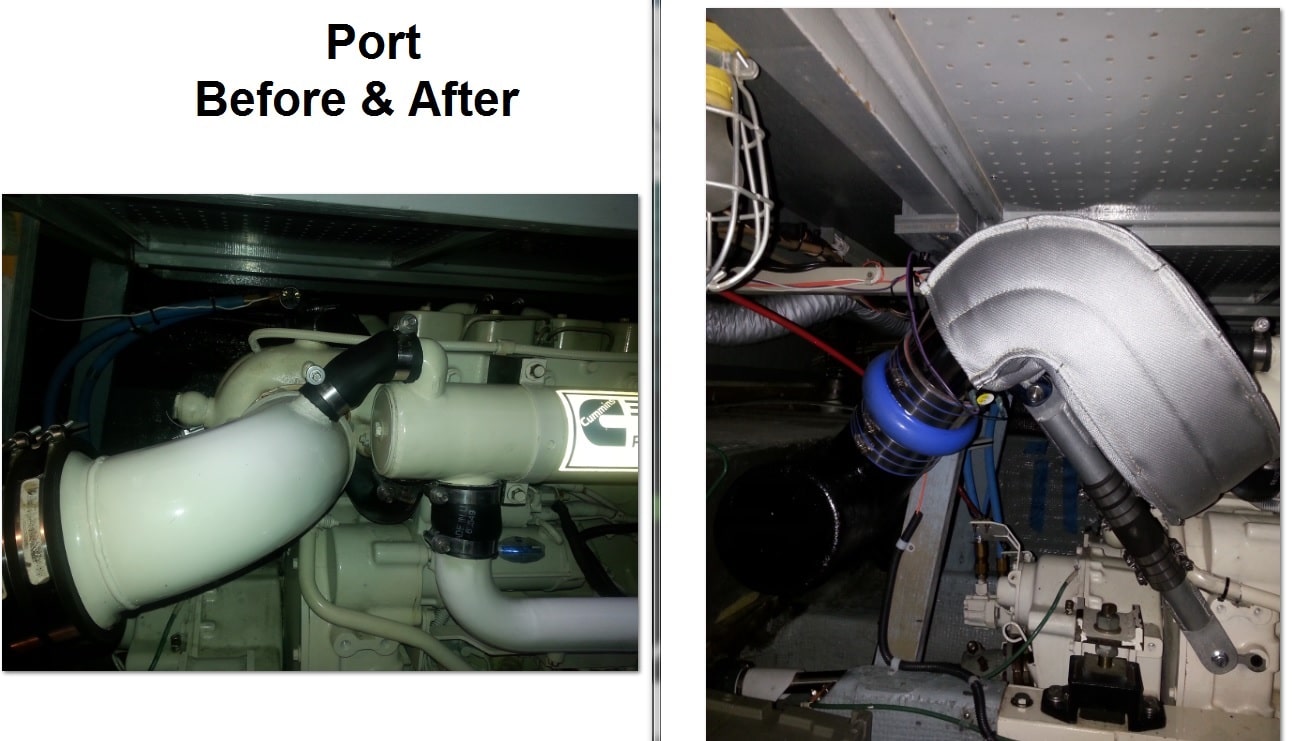

Our dry riser design eliminates the risk of water intrusion into the turbo through the exhaust outlet. It’s really is as simple as making gravity the key design constraint which makes sense when you think about the consistency of gravity, It’s Always There! By ensuring that gravity will pull the water away from the turbo under all conditions the turbo stays dry and happy. Though it’s exceedingly hard to achieve this with off the shelf components, with custom exhaust we can fabricate the geometry to match the constraints of the engine room to optimize the design for each vessel. Coming out of the turbo we turn upwards above the water line, then we turn downwards creating a spillover point that is ideally in excess of 12” above the water line and finally, we introduce the water on the downhill slope. All the while we must avoid the deck, beams and other obstructions, and position the mixing bell for a smooth connection with the existing muffler or wet exhaust.

How will the new exhaust change the layout and functionality of my engine room?