Repower of a 28Ft Bertram done the SEABOARD way (with the owners permission and help, off course)

AUDAX is a beautiful performing 28 Ft Bertram w/ a pair of Yanmar 4LHA 230 HP marine diesels, Hurth 630A 1.5 ratio gears and 18×18 3B cupped nibral props.

We removed all of the old wood stringers, ground out the entire engine room and re-glassed as needed. We built custom 4-point heavy aluminum engine/stringer mounts, floated them in w/ epoxy and then bolted them to the stringer/bulkheads. This gave us the added strength and stiffness that was needed, and allowed better access to the engines. A finish coat of gloss epoxy makes for long lasting, good looks, and easy maintenance.

Getting the engine room ready to fit these high performance diesels

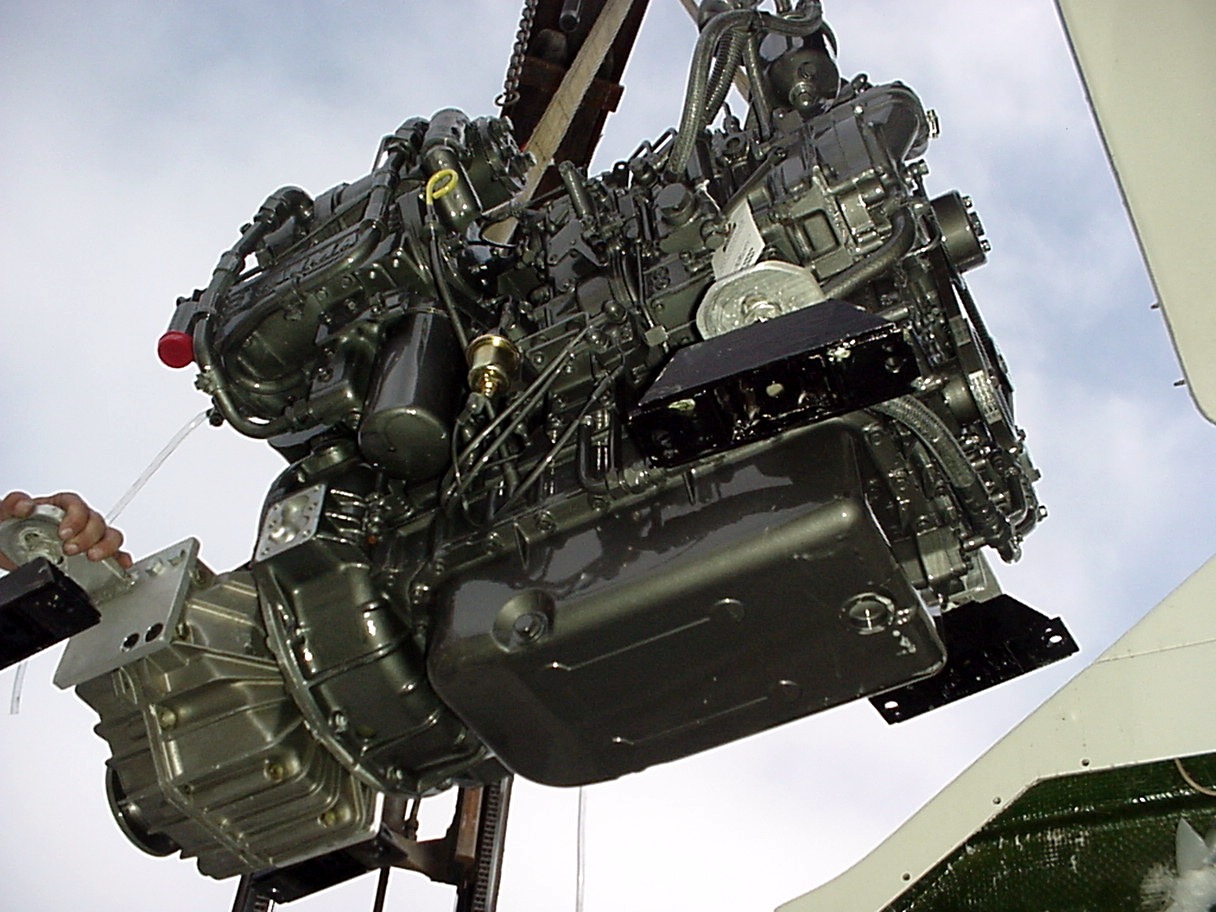

If the prep work is done correctly, the lift in is a simple 10-15 minute process. In this case, w/ 3 guys and a fork lift, both engines were sitting on their mounts in less that 30 minutes from the time we lifted them to setting securely in the boat

Sea trials

A posting (Sept 20, 2000) from the owner, answering some questions on his repower.

Ron, As Tony mentioned I own the 28 shown in his post above. I will provide a general update on the boat for those who are interested. First of all, I an extremely happy with everything that was done to the boat. I run my boat similar to what you do, may be a little less. The job was complete on July 14, 2000 and we ran home on the fifteenth (Oxnard to San Diego, about 135 miles). We now have 165 hrs on the engines. Absolute flawless operation, no problems. As shown in Tony’s pictures, I built my own dash and used Datcon gauges and sending units.

This seems to have been a good choice. As for performance, the boat is doing everything I had hoped for. I have 18X18-cupped props and could easily add another inch of pitch. I run very heavy, 100-gallon bait tank, 265 gallons of fuel and much more. The boat easily runs past the 3300 recommended top RPM. I have made no attempt to establish a top speed, but in a short burst I quickly see almost 30 knots on the GPS (29.8). 3100 RPM in moderate seas would seem to give about 26 knots, I have not run at this speed yet. I have come in from 30-45 miles at about 23 knots and about 2800 RPM. I will probably leave my props the way they are because we frequently need to run in rough seas at 12-14 knots and I do not want to drop off the power band at the lower RPM. I do not have any accurate economy figures, but I believe I am getting about 1.7 to 1.8 km/gal. At 18-23 knot cruise and 3-4km/gal at 7-8 knot troll speed. As an example, last weekend we ran about 70 miles started trolling at 6:30AM powered up to come home at 2:00PM, and burned 101 gallons of fuel.

About 7.5 -8 hours were at cruise of 15 to 20 knots. Many of our recent trips from 30 to 50 miles offshore have resulted in fuel consumption of 44 to 58 gallons. A few comments on what was done to my boat. The rudders were increased in area by about 35-40%; this allows the boat to operate on one engine at an idle. New struts at a shallower angle, new location for shafts thru hull and new shaft angle. All SS fabrication and fiberglass work done by Tony and Frank, his assistant. The two 28’s Tony has repowered both came with gas V8s. These boats have very short engine boxes which makes almost any installation a tight fit. Your engine compartment is substantially longer and will make any change easier. You may want to check the height of you over engine deck, it may be taller than mine. I have been told that there are about 8 different configurations of engine compartments on 28s. Another bit of information, I have a good friend with a 28 foot Topaz with new 200 HP Volvos. We frequently fish close together.

On trips where run time, troll time etc were identical I burned 51 gallons and he burned 68 gallons. At this point I am completely happy with the boat and the Yanmar 230s. Time will tell how they hold up. My boat is a 1975 and I have owned it for almost 10 years. If you have other questions please send me an email and we can exchange phone numbers if you want. Tony, Dan finally said “maybe we CAN take out the side tanks”! Also FYI, I changed the oil at 50 and 125 hrs. and trans at about 63 hrs. and will change both again at 200 hrs. Filled the boat with yellowfin last weekend, when are you and Frank coming down? I am happy to answer any questions that anyone posts regarding my boat……

Bill