From the owners perspective…

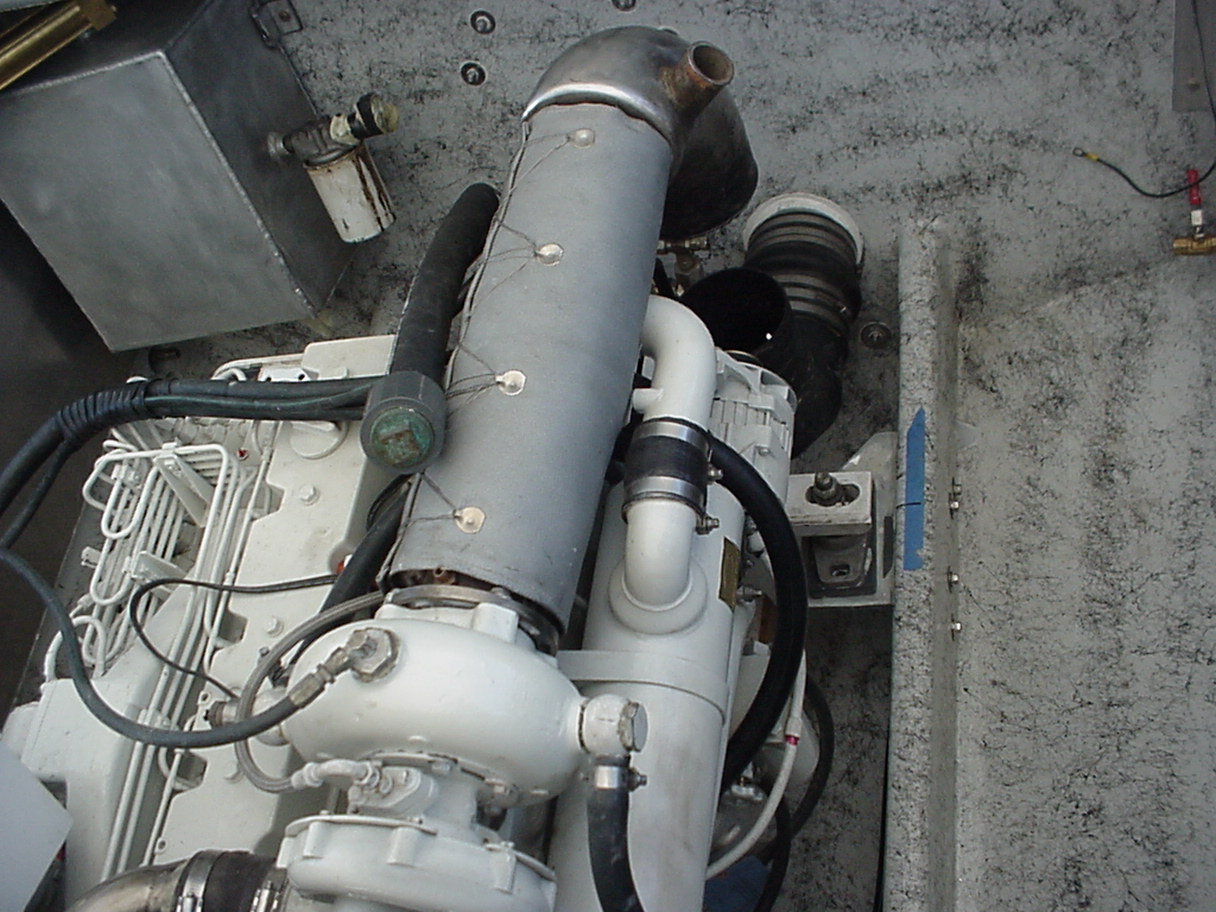

On March 8 2001, I brought my 32×10 Radon to Seaboard Marine for a re-power. Tony suggested I replace my gas guzzling twin 454 bravo 2 package with a single 400-hp Cummins C series and a remotely mounted ZF 302vld transmission.

The first things you notice at Tony’s facility is that you are at a professional yard. The shop is clean and equipped with every tool and marine part you could possibly need. Every part I needed from a new autopilot to custom-machined bearings was in stock.

Tony agreed to let me do as much of the re-power work as I felt comfortable doing. Since I’m a commercial fisherman and would be out of work until the project was completed, I took full advantage of this opportunity. Every morning Tony advised me on the job at hand. When I needed welding or machining done his shop completed it ASAP. Tony provided all the technical advice from fiberglass lay up to shaft angle and alignment techniques.

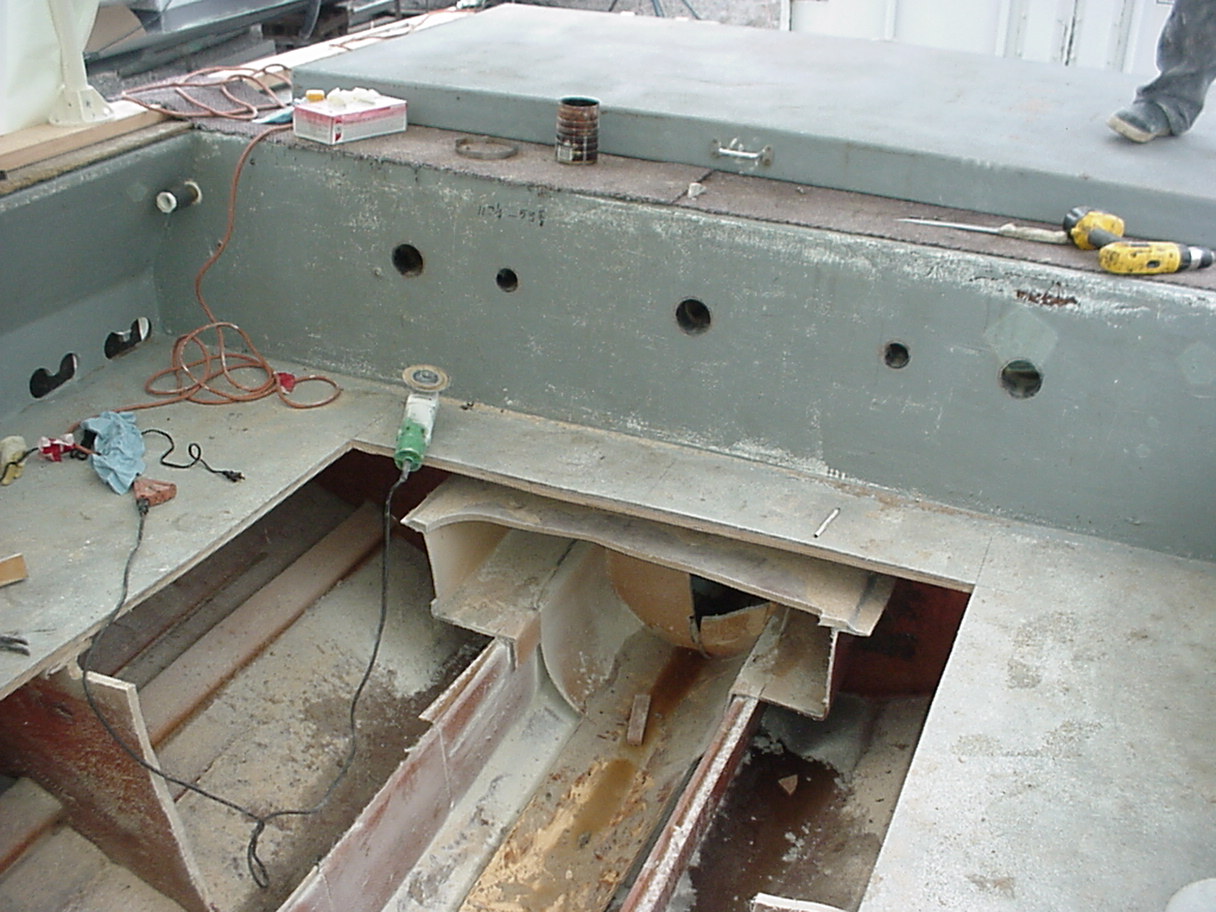

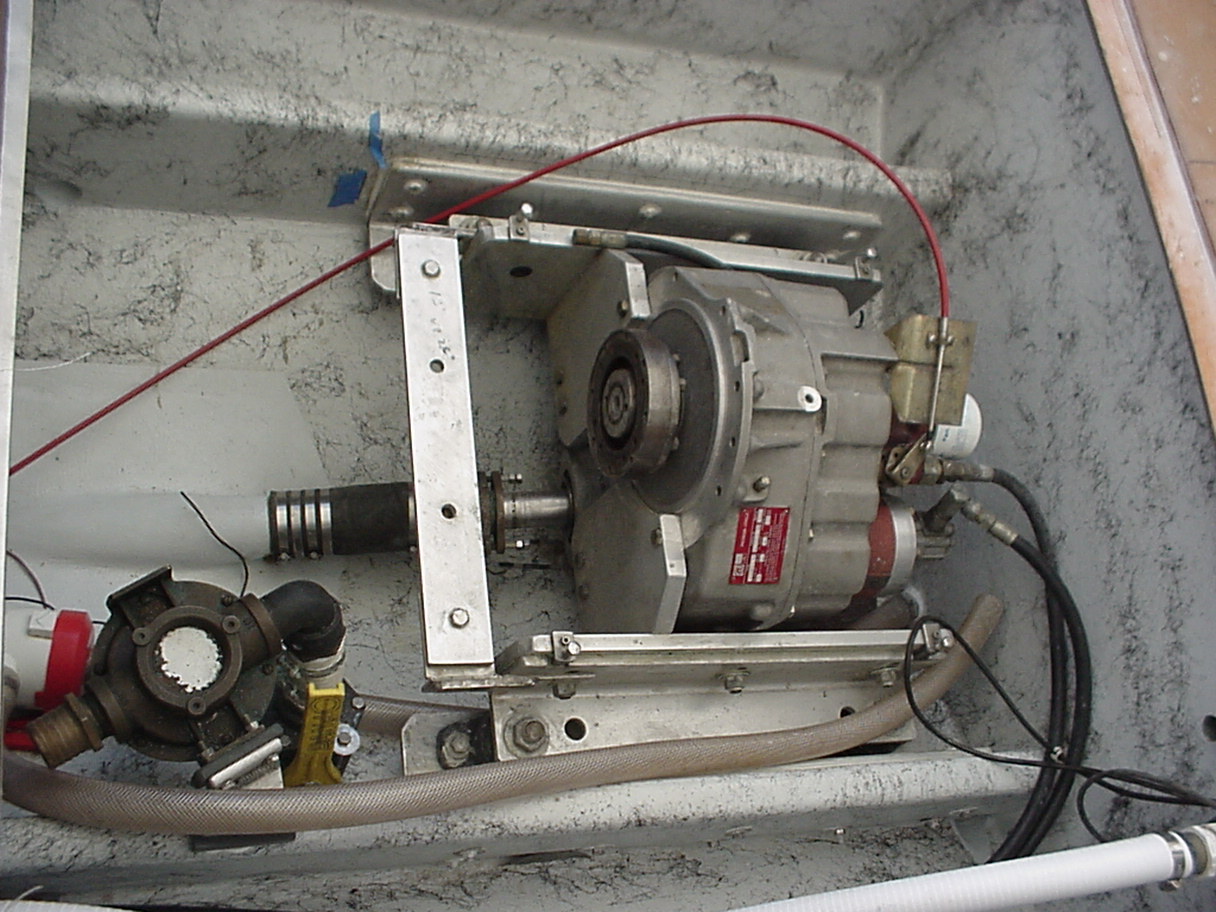

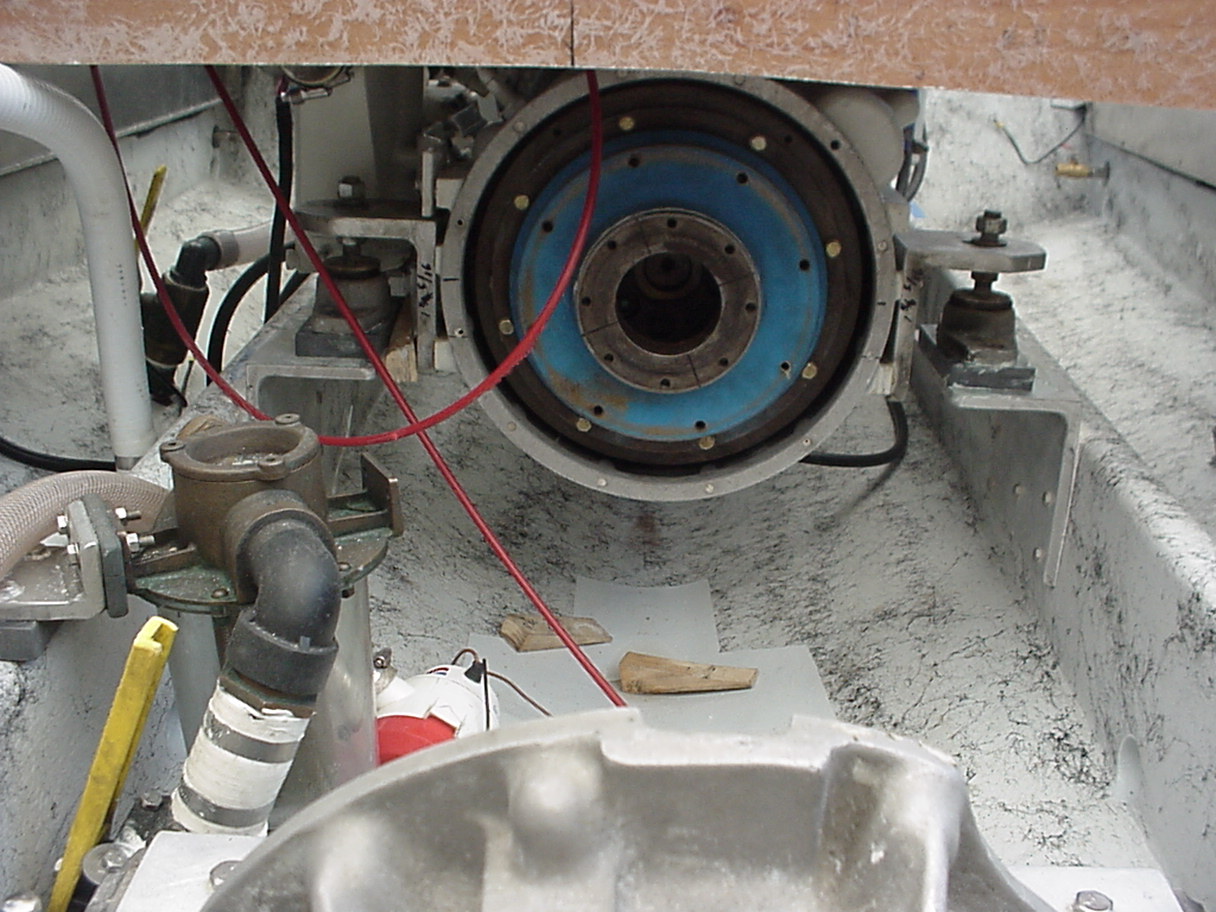

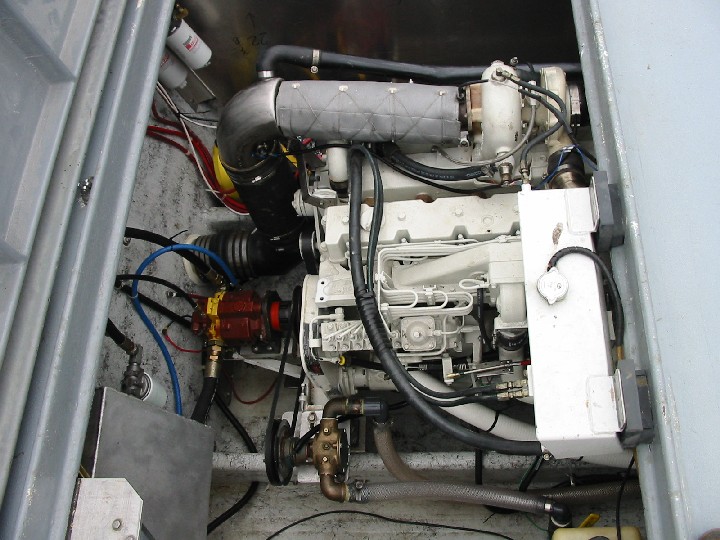

By March 20, the hull was prepared and ready for the transmission installation. The custom transmission mounts Tony builds are superior to anything I have ever seen. They are simple, strong and allow for easy shaft alignment adjustments. A week later we installed the strut a two-inch shaft and glassed in the shaft log. By the middle of April, the engine was securely mounted to the new 9.5x 1.75 microlam stringers. After installing a new electrical and fuel system, we started the engine and I could tell right away that I purchased a real power plant. On April 30, we moved the boat to Ventura harbor, mounted the 26×30 four-blade propeller, and pumped 200 gallons of $1.27/ gallon diesel into the tanks. I asked the attendant the price of gasoline and was told $2.45/ gallon.

The prep work for the stringer install (exact width, etc.) was paramount in allowing the use of the of the power train /v-drive mounts from the “Raptor” which was also going thru a repower at the same time. Basically, the Raptor was upgrading from a Cummins 400 C/ remote V-drive to a Cummins 635 HP QSM-11 with a ZF 350 V-drive(that need for speed again), and the Orion was going to install his complete drive train that was 4 yrs old w/ 6500 hrs on it. Even w/6500 hrs on the on the V-drive, shaft, strut, etc, everything was in like new condition and had proven to be 100% reliable.

Sea trials are the true test of a successful re-power. Tony warned me that my 1989 32 foot Washington build fiberglass radon was heavier than the newer radons so I may not go as fast as some of his other Radon re-powers. The 454s gave me 18 knots @ 3500 rpm with 1000 lbs. of crab on deck. The Cummins 400 gives me 20 knots @ 2200 rpm with the same load. With both live wells flooded (550 gallons) the boat still cruses at 15 knots. I use 60 gallons of diesel to pull the same amount of traps that previously required 140 gallons of gasoline. With this performance, I have reduced my fuel cost by 75%.

Thank you Seaboard Marine,

Chris Hoeflinger