Cummins Marine Diesel Repower Specialists › Forums › Cummins Marine Engines › QSB 5.9L running rough

- This topic has 26 replies, 5 voices, and was last updated 6 years ago by

David Hays.

David Hays.

-

CreatorTopic

-

February 18, 2017 at 2:21 pm #15478

i started the engine today after a bit of time without running, a couple months. In the meant time the only thing that has been done to the engine was adding a pan heater and changing the zincs.

Today the engine started up fine but was running extremely rough. It gradually smoothed out but now occasionally it will sound like it again seems to be fine.

I don’t know engines at all so am at a loss. I will say that the Smartcraft display is reading a fuel burn rate that is way too low. When installing the pan heater, I was working around the electrical connections on the port side of the engine. Is it possible that I disturbed one of those? If so, any suggestions on which to check out?

-

CreatorTopic

-

AuthorReplies

-

May 20, 2017 at 8:05 am #18865

Problem Resolved (and Tony is right again)

For some reason the font color in the reply window is a very light gray so I can hardly see it. If anyone knows ho I messed that up, please let me know.OK, so the problem went away when the mechanic disconnected the alternator. Taking the belt off helped some, but disconnecting the wiring from the alternator eliminated the problem altogether.

The boat has had two charging setups for the start battery. A Blue Seas ACR that combines the house and start bank whenever there is a charge voltage to the house bank, and a Balmar Duo Charge that charges the start battery whenever there is a charge voltage at the house bank. At some point I changed from the ACR to the Duo Charge. The problem didn’t occur right away but when now when I setup the ACR the engine runs fine. When I setup the Duo Charge the engine runs terribly.

The first thing that I thought of was a comment Tony made in the Trawler Forum about not letting the engine battery “talk to” other batteries. This is just one example of why I suppose. Tony’s comment at the time didn’t make any sense to me at the time. It certainly does now.

For my own curiosity, I need to see if the Balmar Duo Charge was operating correctly. Maybe it wasn’t getting the voltate of the engine battery high enough? Maybe it was sending to high a charge current to the start battery? Maybe it was just sending some very odd electrical pulses to the battery that confused the engine ECM? I don’t know. Now that I have an engine that is running as it should, I can do some investigating to satisfy my own curiorsity.

BTW, the idea to investigate the alternator came from the mechanics at Cummins Northwest who were hashing over my problem. One of them had a similar experience with this engine in a commercial road application. In that instance, the problem went away when the alternator belt was removed and the problem ended up being a bad alternator. This prompted my mechanic and I to look in that direction. Without that nudge in that direction, we would still be chasing our tails and throwing more parts at the engine.

May 12, 2017 at 5:06 pm #18585Hi Tony,

I agree about needed some better instrumentation. That is something that I want to do and will likely do in the near future.

Today was a long frustrating day.

Engine still runs rough. Still the same issue.

I have a bit more detail. The engine has been consistently throwing a code (2275?) that indicates over voltage or short to high on the lift pump. The lift pump was just replaced.

Not surprising given your post here are some other odd behaviors.

The problem goes away when the fuel pressure sensor on the rail is disconnected. The rail fuel pressure jumps all over when running. This is what prompted the mechanics to try pulling the sensor. The problem also goes away when the fuel actuator is pulled. As I understand it, these regulate the fuel pump behavior. With these disabled the rail gets the full 25k psi fuel pressure and the engine runs smoothly. Occasionally, there has been another code indicating a high voltage or short to high in the fuel rail pressure sensor, but that code is intermittent.

It appears that at some point in the past, the fuel pump actuator and the fuel rail pressure sensor have both been replaced. I don’t have the records from the PO to confirm or know when and why.

The trouble shooting tree for the codes given was inconclusive. However, at times manipulating the harness would cause the codes to go away or return. However, most of the time the lift pump code is active and the fuel pressure sensor short code is not.

The engine starts quickly, no smoke, and runs very rough. Again, with either the actuator or fuel pressure sensor pulled this doesn’t happen.

The mechanic happened to have a test ECM in his truck. With that connected there was no change in the behavior.

Our first thought was the pressure sensor, but it is newer and wouldn’t explain the intermittent high voltage codes for the lift pump. It could be the fuel pump actuator, but no codes point in that direction. Since messing with the harness can cause some of the codes to appear and disappear we are wondering about a problem there even though we can’t find any definitive problems with a multimeter or visual inspection.

At this point I would be happy to try the pressure sensor and actuator, and if that doesn’t solve the issue then possibly replace the harness. I am grasping at straws at this point and so are the two Cummins mechanics.

May 6, 2017 at 5:57 pm #18301

Tony AthensModeratorVessel Name: Local Banks

Engines: QSB 6.7 550 HP

Location: Oxnard, CA

Country: USA

David, I am going to go back a month or so as this will not change…….You are “driving blind”, plus you have the worst of the worst to tell you what may be going on…. ZERO instrumentation as to helping you, you have “SMARTCRAP” , that IMO is not well supported at all ( you have seen that), and you are dealing with people that are not guiding you right at such low hours.. Never replace injectors with a symptom like you are experiencing until you do the “cheap things” first.. Plus, if you have bad injectors at such low hours, you need to ask yourself (or them) why? ——————————They just don’t do that.. You need to replace the following 1st————Position sensor ( cheap), fuel actuator ( cheap), and fuel pressure sensor(also cheap)…………….. All three of these things can cause the systems you have.. Maybe all 3 at $400 and a hands-on owner can do it, vs one injector at $1200+?

May 5, 2017 at 10:03 am #18267Another update

I finally gave up on the shop that was working on the engine. Their Cummins tech is out, they can’t get their Cummins diagnostic software to work, and their scheduler keeps dropping the ball. I have been waiting three weeks for them to get back to me as to how they will solve my problem. I haven’t received a bill from them yet, and not sure how much of it I will pay once I do.

I finally called Cummins Northwest and they had a mechanic come out today. After 15 minutes they were able to tell me that it appears that #2 injector is sticking on start up and then still not behaving well.

One thing they found was that all of the injectors may have some issues. When they cut out each injector, it doesn’t affect the engine as much as they are used to seeing on these 5.9L common rail engines. Their impression is that likely all of the injectors may have some carbon build up. They felt that replacing the #2 injector would likely solve my immediate problem but the mechanic recommended I consider replacing all of them.

Being completely ignorant, I am at the mercy of the their recommendations. At this point (depending on what the quoat ends up being) I am tempted to have them replace all the injectors. Only 1000 hours on the engine but most of that has been at a relatively light loading. Not sure of course because I have only put a bit less of a 1/4 of those hours on the engine in the year that I have owned it. Most of the hours I have put on has been in the 1400-1450 rpm range.

Any thoughts on replacing 1 injector vs all 6?

March 25, 2017 at 7:23 am #16682Update

OK, sorry it has taken so long to get back to this. I appreciate the information you have given so far.

The kid put in the new lift pump last week to no effect. He still had a read-only version of the Cummins software that wasn’t fully functional. He was stumped. He went back to the shop to regroup.

I got a call from the service manager this week who said that they got their normal laptop back which has the complete version of the Cummins software and would send the kid back out yesterday. Kid showed up with the “fixed” laptop as well as the gear to test the fuel return to see if there was air getting into the fuel causing the fuel knock.

Well, the laptop apparently had been sent to John Deere because it wasn’t working well with their software. Deere fixed it so it did. Now it wouldn’t recognize the USB port when the Cummins adapter was hooked up. As the kid said, “we just wasted your time”.

He did check the fuel return and found no bubbles at all coming out of the return line. Another thing that is working great on an engine that is running terrible. His thought, once the laptop is “fixed” again, is to come out and bring two parts with him. He pointed them out, but one I think was a fuel pressure valve? And I can’t recall what the other was. He didn’t think they were necessarily bad, but…. If he can’t find any codes on the computer, then with a working software connection he was thinking about doing some testing on the injectors and if those seem OK then do some cut out testing to see if it is particular cylinder that is creating the problem.

Believe me, if there was another decent option in my area, I would jump ship and find another shop. The problem is that while they are having issues, they are still the best option I have found. I can only go out to the boat to have them work on it on Friday’s. Which means a week between visits. This is getting beyond frustrating.

To recap: The engine starts quickly but runs rough. The mechanic says that it is a “fuel knock”. After a few minutes it mostly smooths out, with the periodic hiccup. It will run that way until the rpm is push up to about 1500, then the knocking gets worse again. Bring it down to 1400 and it smooths out again. Still, the GPH reading at the tachometer is only about 1/2 of the actual fuel flow. Before when the Cummins software was working, the reading the computer was getting on fuel burn was what I would expect but didn’t agree with the GPH display on the tachometer.

March 16, 2017 at 9:33 pm #16373Update

I finally got a mechanic down to the boat last week with a laptop and the proper adapters so he could check the codes. The only fault codes being thrown were from the lift pump. I don’t know exactly what the code was but the mechanic explained that it was a fault there. He checked all the connectors and everything else and said he thought they were fine. The rough running (loud nasty sound) he said was a fuel knock. His recommendation was the replace the lift pump. Turns out he had just been looking at a lift pump for my engine sitting on his work bench for another Cummins 5.9L that also had a bad lift pump.

He is supposed to install the new pump tomorrow, so we will see if that solves the problem. I will report back.

I still think that I would like to be able to to install an SMX display. After this experience, I feel like I’m flying blind.

March 7, 2017 at 10:08 am #16090

Corey SchmidtForum ModeratorVessel Name: Rebel Belle

Engines: Cummins

Location: Oxnard, CA

Country: USA

Update…

Yes David, do you have an update on things? Any progress?

March 6, 2017 at 11:33 am #16051

Clark LeighsParticipantDavid,

Don’t know if you are still reading this thread and these guys are way ahead of me but you might check the actual clearance between the crank sensor and the actual cog wheel. I don’t know that the clearance should be but in my different job I worked with hundreds of similar sensors and there is a maximum clearance beyond which they may read but erratically which may be why the engine is rough; it sometimes gets a good signal, sometimes not. Find out what that clearance is. I have also seen them lose a tad of sensing range as they age . When originally set for position they read but they were set too close to the max. range so as they age they lose that tiny bit of range and an adjustment will take care of it. You may have disturbed it while installing the pan heater.

No comment on the readout you have.

February 25, 2017 at 6:25 am #15733

Rob SchepisForum ModeratorVessel Name: Tenacious

Engines: 6BTA 5.9 330's - "Seaboard Style"

Location: Long Island, NY

Country: USA

Seaboard Marine on YouTube

Going directly to YouTube you will find numerous videos of many different engine startups, how-to’s, etc.

Here’s the YT Homepage link:

https://www.youtube.com/user/SeaboardMarineInc/feed

And here is the link to the YT videos with an “SMX” query:

https://www.youtube.com/user/SeaboardMarineInc/search?query=smx

February 24, 2017 at 7:27 pm #15725Going forward and looking at the big picture, an upgrade to the SMX Display(s) would allow you to see the same parameters and fault codes as the laptop plugged in by a Cummins tech

I swear I saw a video on the Seaboard website that demonstrated it, but I can’t seem to fine it.

February 24, 2017 at 7:25 pm #15724This will eventually makes sense & “cents” if you keep the boat & as time goes by…………You own a boat with a very sophisticated engines. In fact, your engine is one that is used as a standard to what many are gauged by.. In so many words, you have a really great engine, but one with nothing to “see” what it is doing.. .The builder/installer of the vessel “cheaped out” so to say, and installed it so you are “Driving Blind”……..Unless you are willing to upgrade your engine monitoring system, I am afraid that you will never to be happy and issues like this will happening as long as you own it.. Hiring someone from Cummins or an independent mechanic will be $$ ill spend as your base issue will not be solved.. You need a “PROPER” engine vital sign monitoring system———— That is “Plain & Simple”.. Tony

That makes a lot of sense Tony. I have wondered about what it would take to add the full Smartcraft monitor (or whatever it is called). If you have a link as to what would need to be done to add it, I would like to read up on it.

February 24, 2017 at 6:34 am #15666

Rob SchepisForum ModeratorVessel Name: Tenacious

Engines: 6BTA 5.9 330's - "Seaboard Style"

Location: Long Island, NY

Country: USA

Going forward and looking at the big picture, an upgrade to the SMX Display(s) would allow you to see the same parameters and fault codes as the laptop plugged in by a Cummins tech

February 22, 2017 at 6:20 pm #15629

Tony AthensModeratorVessel Name: Local Banks

Engines: QSB 6.7 550 HP

Location: Oxnard, CA

Country: USA

This will eventually makes sense & “cent” if you keep the boat & as time goes by…………You own a boat with a very sophisticated engines. In fact, your engine is one that is used as a standard to what many are gauged by.. In so many words, you have a really great engine, but one with nothing to “see” what it is doing.. .The builder/installer of the vessel “cheaped out” so to say, and installed it so you are “Driving Blind”……..Unless you are willing to upgrade your engine monitoring system, I am afraid that you will never to be happy and issues like this will happening as long as you own it..

Hiring someone from Cummins or an independent mechanic will be $$ ill spend as your base issue will not be solved.. You need a “PROPER” engine vital sign monitoring system———— That is “Plain & Simple”..

Tony

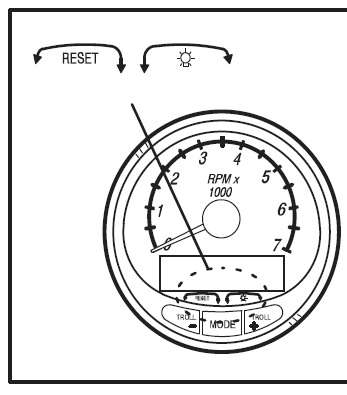

February 21, 2017 at 10:54 pm #15613I had written a reply but must not have submitted it. I’ll try again.What EXACT display or instruments do you have–Let me “SEE” your dash or helm.. Are you saying you DO NOT have a full digital display and all you have is a TACH with a “blinkcode window” ?? IF SO, you are not in good shape as it’s close to impossible to troubleshoot anything.. Smartcraft is bad enough, but without a full display, I would have no clue what may be going on.

I don’t have the full digital display, only the tach with the blinkcode window. So since that is the case, unless I find something obvious in the electrical connections or the speed/position sensor that Corey mentioned, am I at the point where I should get a Cummins mechanic out so they can read the codes in the ECM to see what is going on? I can pull apart, clean, and reconnect all the connectors there on the port side of the engine but that would be trial and error fault finding. One of my concerns is possibly doing any damage to the engine by having it not running well and by doing a number of cold starts as I try to find the problem. Is that a valid concern?

Think a bit–Does it seem to be worse when the fuel in lower in the tanks? Tony

Not enough information to tell. Initially the engine was started on a tank that is almost full. I did try switching to the other tank that was 3/4 full but that didn’t make any difference.

Rob, thanks for those pictures, they will be helpful.

February 21, 2017 at 6:53 am #15585

Tony AthensModeratorVessel Name: Local Banks

Engines: QSB 6.7 550 HP

Location: Oxnard, CA

Country: USA

What EXACT display or instruments do you have–Let me “SEE” your dash or helm..

Are you saying you DO NOT have a full digital display and all you have is a TACH with a “blinkcode window” ?? IF SO, you are not in good shape as it’s close to impossible to troubleshoot anything.. Smartcraft is bad enough, but without a full display, I would have no clue what may be going on.

Think a bit–Does it seem to be worse when the fuel in lower in the tanks? Tony

February 21, 2017 at 6:19 am #15582

Rob SchepisForum ModeratorVessel Name: Tenacious

Engines: 6BTA 5.9 330's - "Seaboard Style"

Location: Long Island, NY

Country: USA

QSB 5.9 SmartCraft version 1.0

David,

This will help you with identification and nomenclature

February 21, 2017 at 5:19 am #15573

Rob SchepisForum ModeratorVessel Name: Tenacious

Engines: 6BTA 5.9 330's - "Seaboard Style"

Location: Long Island, NY

Country: USA

More Pictures

David,

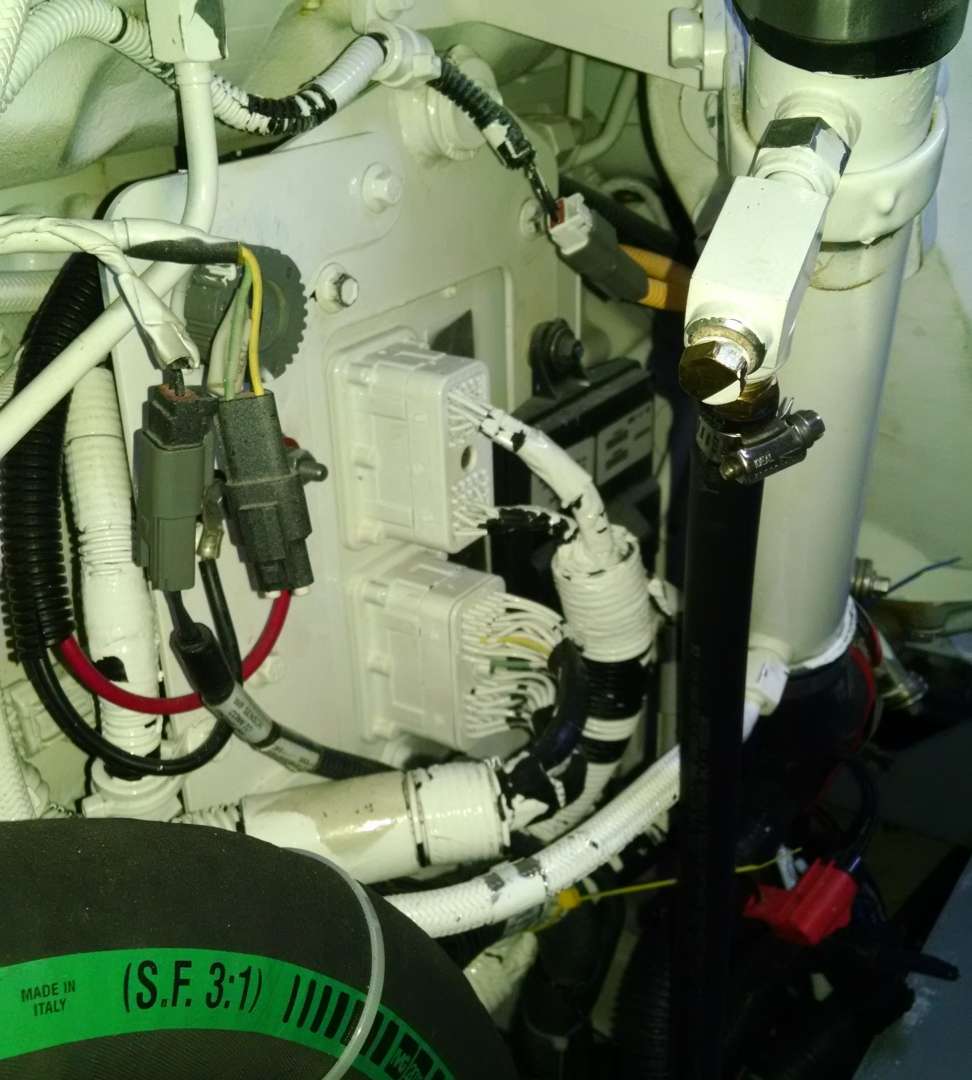

Yes the sensor is up front behind the plastic belt guard and crank pulley. Here’s more pics. I’m also posting all of the pics you emailed to us.

February 20, 2017 at 10:45 pm #15570Hi Tony,

We made it back to the dock. After running really rough and displaying the “Check Engine” on the Smartcraft display, it started to run better again. It would still miss a beat every couple of minutes. I am off the boat now otherwise I would shoot a picture of my display but this is the one I have.

This is the best image I have of the ECM.

Corey,

I will have to look when I get back to the boat (probably not until this next weekend). From the photo that you linked, is that sensor just behind the plastic cover which is over the front of the engine? I did have to remove it, to remove a floor panel in the ER when I was installing the pan heater. Given the tight space, I suppose I could have moved or dislodged it. Being completely ignorant, does that sensor track the speed or position of the crankshaft?

Thanks again for the all the assistance. Unfortunately I will be having to actually work in the office this week instead of working on the boat. Not sure why working in a comfortable office, wearing clean clothes, not having to do anything more strenuous than typing on a keyboard isn’t nearly as enjoyable as crawling around a too-small ER getting banged up and dirty not having the foggiest idea what I’m doing?

February 20, 2017 at 7:15 pm #15568

Tony AthensModeratorVessel Name: Local Banks

Engines: QSB 6.7 550 HP

Location: Oxnard, CA

Country: USA

What EXACT display or instruments do you have–Let me “SEE” your dash or helm..

I want to SEE the ECM side of your engine

Think a bit–Does it seem to be worse when the fuel in lower in the tank?

Tony

February 20, 2017 at 6:30 pm #15567

Corey SchmidtForum ModeratorVessel Name: Rebel Belle

Engines: Cummins

Location: Oxnard, CA

Country: USA

Position Sensor…

Let’s make sure that your position sensor is doing it’s job and is still mounted correctly… if it’s not the engine will do very funny things…

-

AuthorReplies

You must be logged in to reply to this topic.