- This topic has 12 replies, 5 voices, and was last updated 7 years ago by .

-

Topic

-

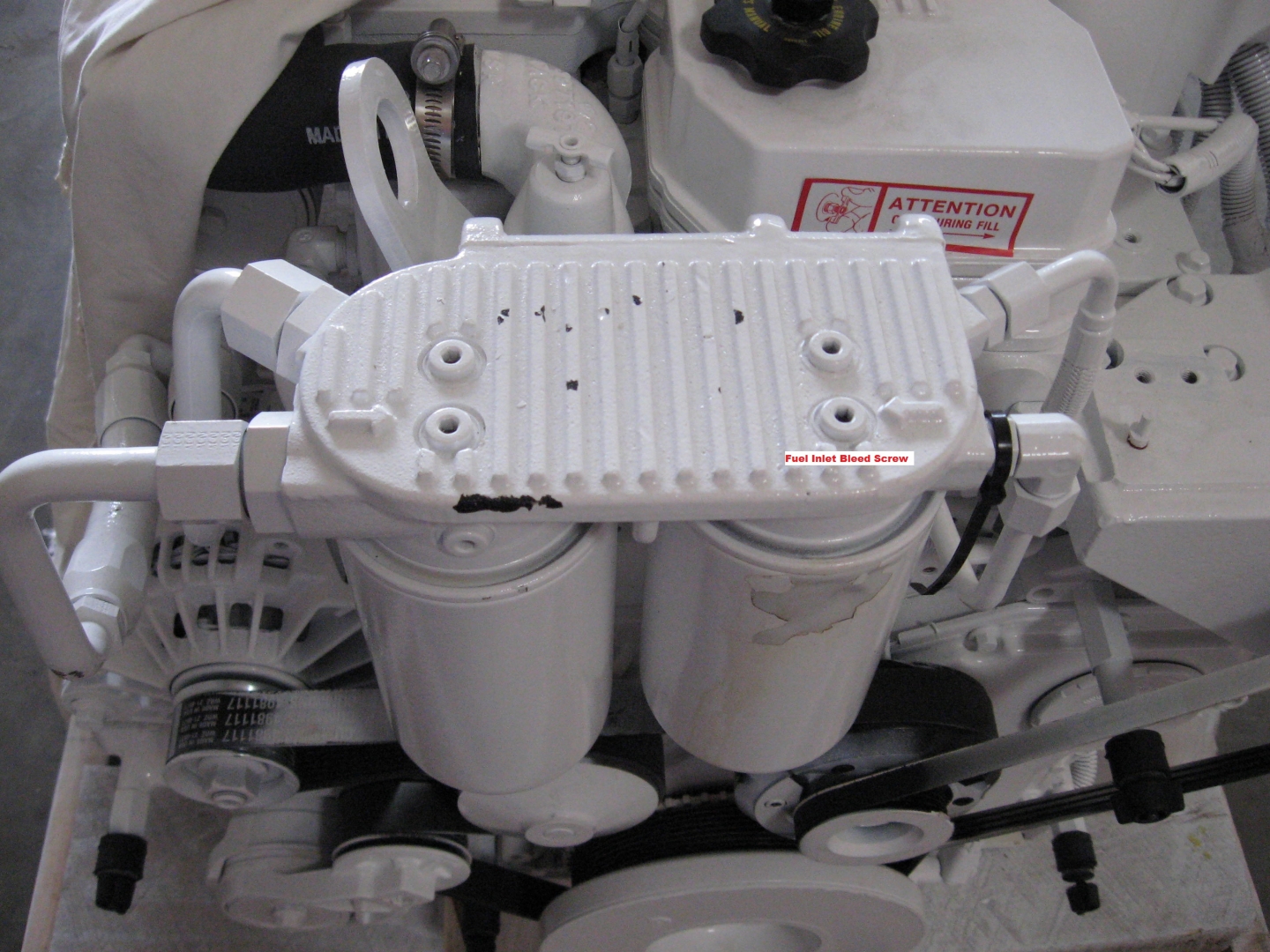

Diesel novice here, that is in third year of ownership of twin diesels on a 36FT express. The engines ran flawless all summer, and on the last run to the winter storage facility, which also built the custom express. Had 1000 hour service performed on pair of 2008 Cummins QSC 8.3 600 HO engines by factory techs. Complete heat exchanger dismantle and pressure test. One week prior, storage yard changed Racors and in-line fuel spin on filters. I was present at the time of the filter change, and Racors were primed, but in-line filters were not primed, “per Cummins recommendations”. Factory Tech re-assembled engines and sea trial was arranged. Tech was informed new filters were installed. Boat was dropped in the water for sea trial, with myself, Tech, and yard personnel in attendance. Port engine was difficult to start, but after 12-15 cycles of “key switch prime”, engine started. Starboard engine would not start after 15-20 cycles, and bleeding of lines by Tech. Long story short, starboard engine required new fuel pump??? Am I off base thinking that priming the engines this way may have contributed to the failure of the fuel pump? Again, engines were running fine all season, but a change of fuel filters and 1000 hour service and heat exchanger, sea water pump, gear oil cooler, after-cooler, etc. check results in a new fuel pump required? Thanks for your input.

You must be logged in to reply to this topic.