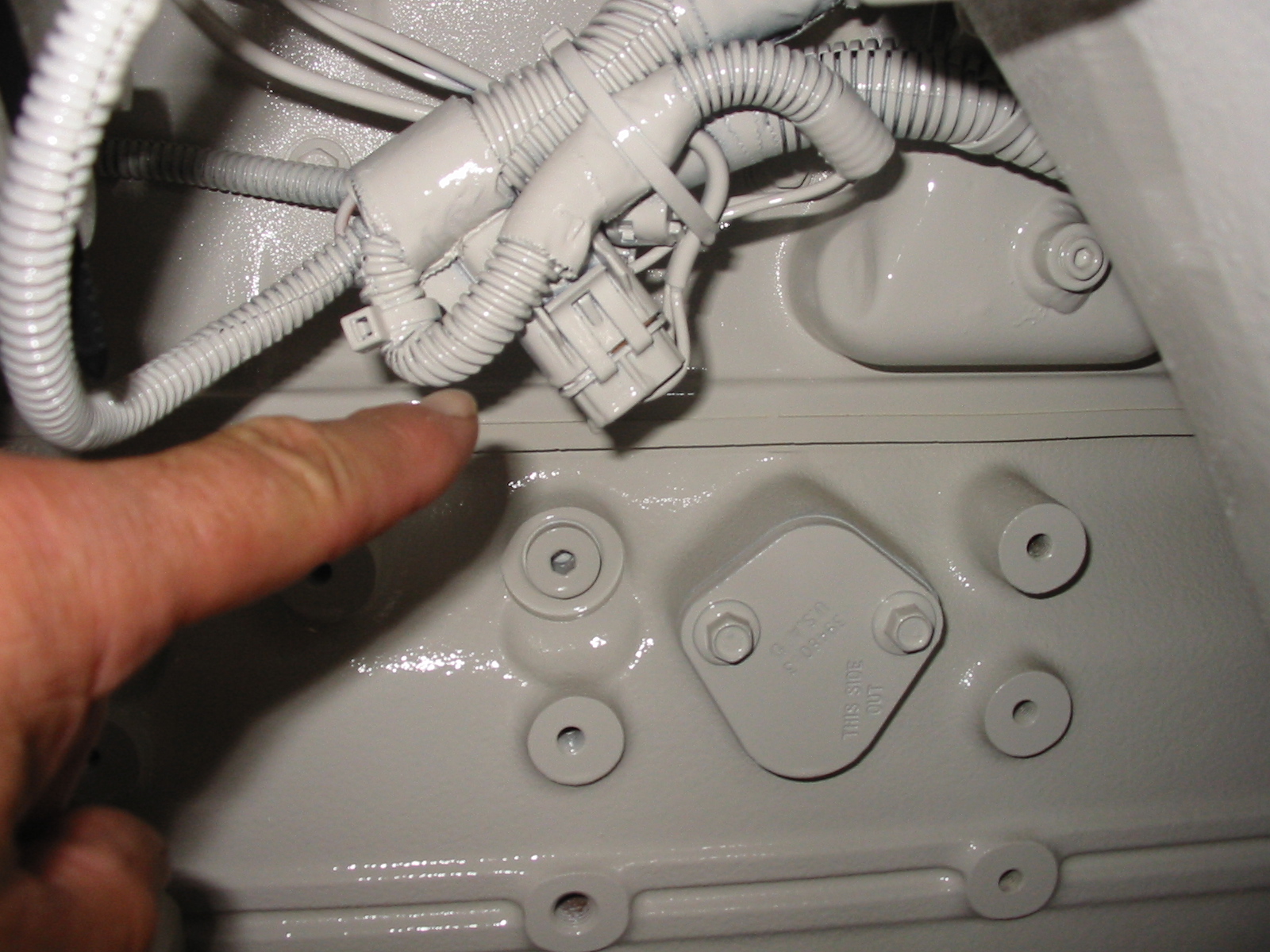

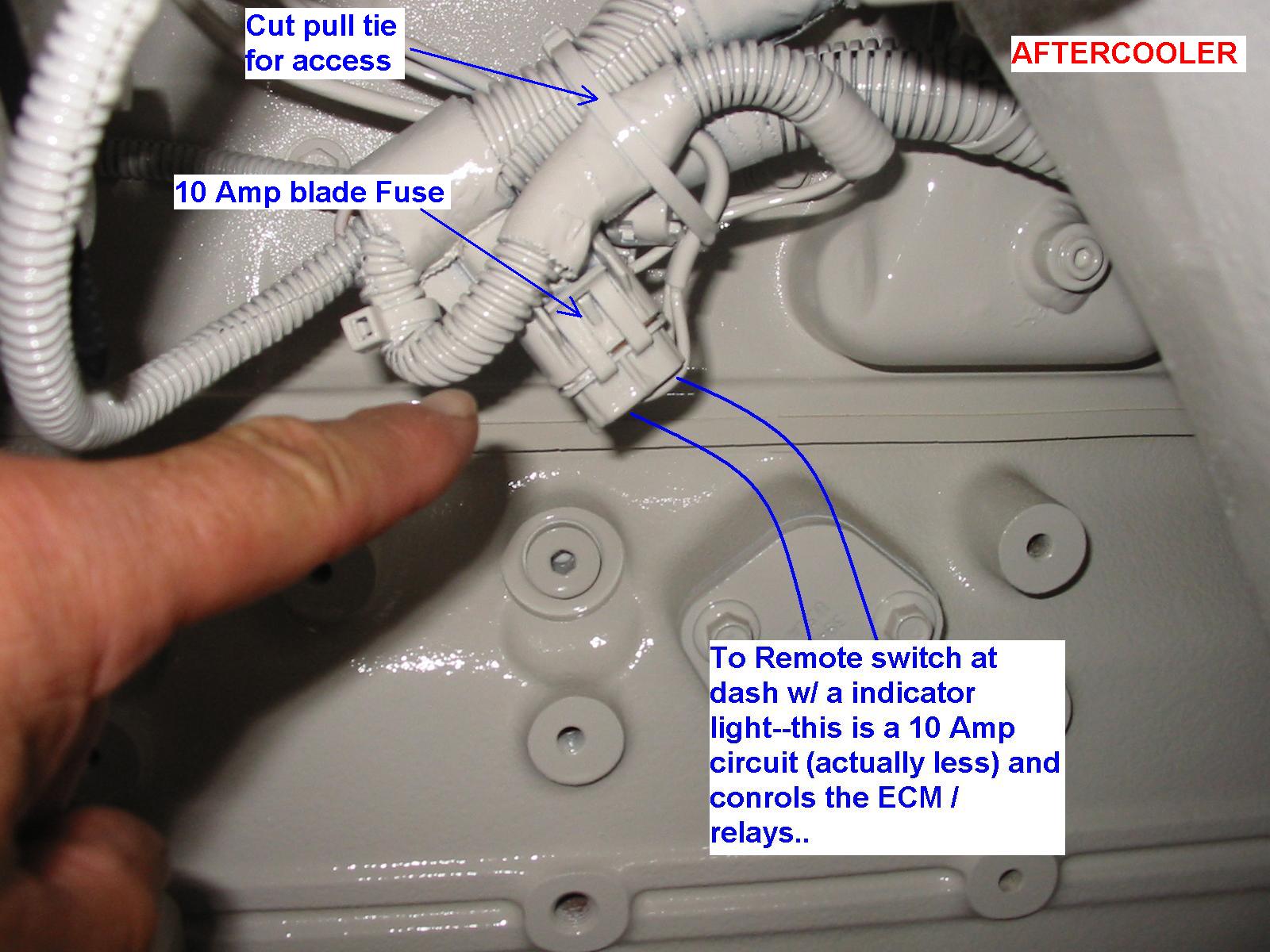

Many times it is often necessary to either remove or at least disconnect the Cummins Marine air heater. The complicated air heater circuit on a Cummins Marine diesel can have a tendency to not function as expected and is very difficult to troubleshoot when things do go wrong. If you decide that you want to keep the heater circuit on the engine which includes the ECMs, sensors, and harnessing, then you have a couple options to either disable the circuit entirely and switch to oil pan heating or create a manually controlled heater. To disable the circuit, just pull the air heater circuit fuse located in the image below. A manually controlled heater circuit can give you much more flexibility so that you do not run down your batteries and you can utilize the heater circuit at the times you feel it is needed most… see the image below on how to setup a remote switch and indicator light for manual heater control.

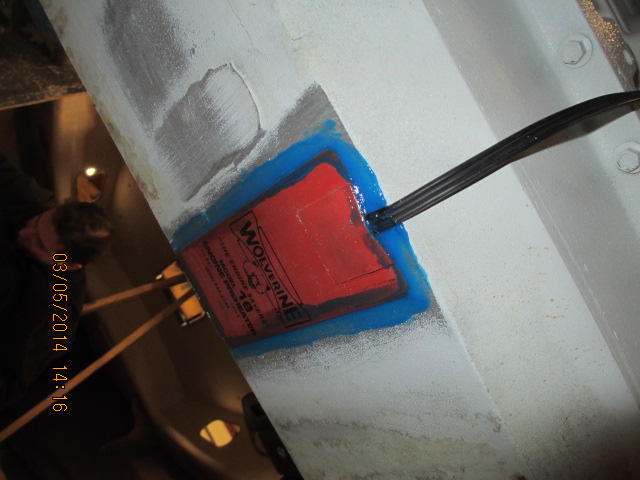

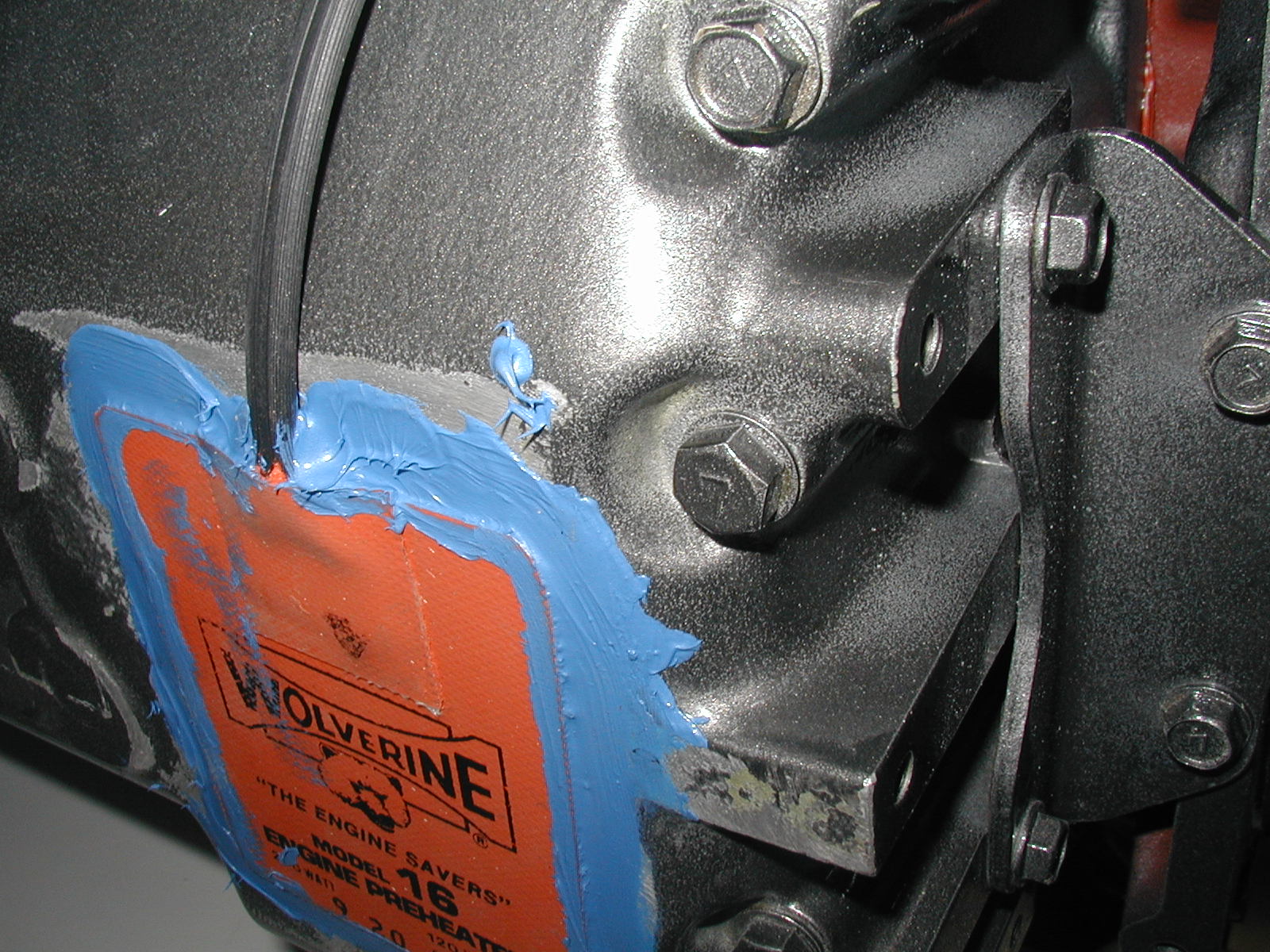

Best Option for Engine “Pre-Heating” – Wolverine Oil Pan Heaters

The best options for engine pre-heating are 100% the Wolverine oil pan heaters. The heater pads are installed under the engines oil pan (preferred) or sometimes on the side of the engine oil pan if access is super tight. When installed correctly, a 250W wolverine oil pan heater is way more effective vs. the factory air heater because the ENTIRE mass of the engine is already warm. The 120V heaters when operating at the dock 24/7, will not only keep the engine nice and cozy warm but will also keep the engine room temperature right where it should be to avoid condensation, etc. No need to be concerned about running the heater 24/7 as the engine acts as a giant “heat sink” to keep everything right where it should for the long-term. When using the 250W heater, the best engine size range is between a 1,000 to 3,000 lbs. of total engine/transmission iron mass.