The air around us contains vast amounts of moisture. It’s always there and the amount averages (leaving out the extremes of the world) from about 30% to 75% measured in relative humidity. Of course, if you are like me, the term “relative humidity” kinda relates to how uncomfortable I feel in the middle of a hot day and is not much use in the practical life of diesel engines. Or, you might just say “Relative to What?” What I like is this term “Absolute humidity,” which is a measure of the amount of moisture in the air; OR the weight of water vapor per unit volume of air.

What we all need to really understand is how much water is actually in the air around us. I’ll try to explain it this way, at least this is the way it makes some sense to me.

A typical modern turbocharged diesel producing 300 HP will consume about 1500 CFM of air at this HP output level. Ambient air at 80 F can hold about 35 grams of water per cubic meter of volume at 100% saturation (got that from a chart from a lecture at UC a while back)… On a typical nasty late 80 degree F afternoon when the humidity is at 70%, that would work out to about 2 1/4 lbs of water vapor being consumed by the engine per minute running at 300 HP output (check my calcs to be sure I didn’t screw up). Now, let’s take that “captive air” that’s being fed from the turbo through the seawater cooled aftercooler. When the hot air touches the relatively cool tubes/fins , you have a perfect medium for a percentage of that air to cool sufficiently to reach its dew point and condense on the tubes/fins and form water droplets which can (and do) fall to bottom of the aftercooler housing (don’t forget, for air to condense, you MUST have a surface for it to attach to). But also realize, even if it didn’t condense, the engine is still eating this water without harm (the water is in the air anyway), but under the right conditions, the water droplets form in the aftercooler and sits there until the conditions are right for it to go back into a vapor form and get fed to the engine again, and again. This process is a continual one and at times, the aftercooler on a Cummins 6CTA 8.3 may have about 3-5 ounces of “loose” water” in it, and then, that water will just “go away.”

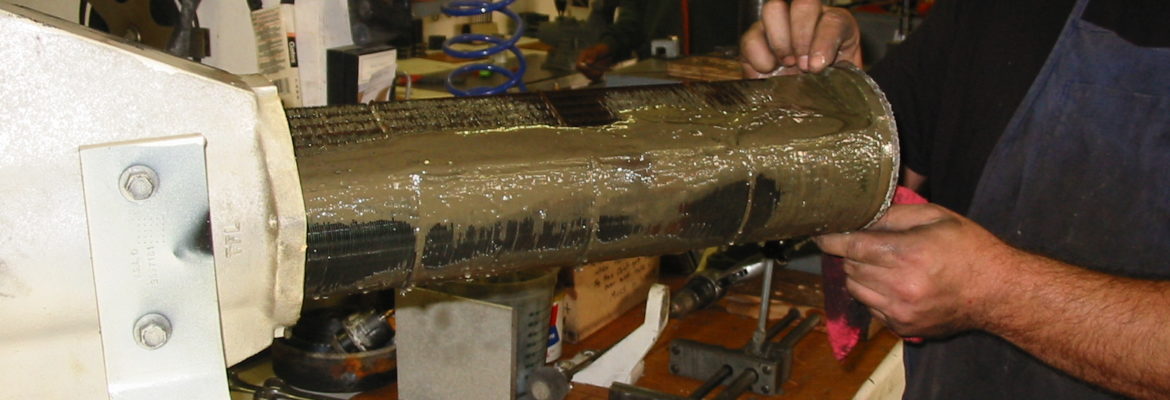

During the course of our business we service about 2-3 aftercoolers per month, and many of these servicings happen the morning after the customer worked the entire previous day, came into the harbor late w/ the sun going down, he had just come off “plane” and idled to his slip for 5-10 minutes before shutting down.. Next morning he removes the cooler and brings it to me. This seems to be the case when we can find a few ounces of water in the coolers (tip it over and it spills out). I’ve had to show many customers that this is NOT salt water (a leak) but “condensation”……I just taste it in front of them and offer the same………Usually, no takers…

Anyway, the water in the aftercooler is sometimes there, and sometimes not . But it’s always in the air and it doesn’t hurt the engine. As far as a “drain hole” (ala Volvo)?? May have some value and I’ve wondered about a small leak/weep hole in the right spot on a Cummins aftercooler many times. It’s not the water going into the engine that bothers me, it’s the water sitting in the aftercooler causing unnecessary corrosion. But of course, that’s a another topic for the couch engineers that designed an aftercooler with many preventable design flaws that can lead to less than a long term life, especially with less than a prescribed sensible and applicable maintenance schedule in the O&M manual furnished w/ these engines.