This is our Standard operating Procedure (SOP) for 20+ years……………….

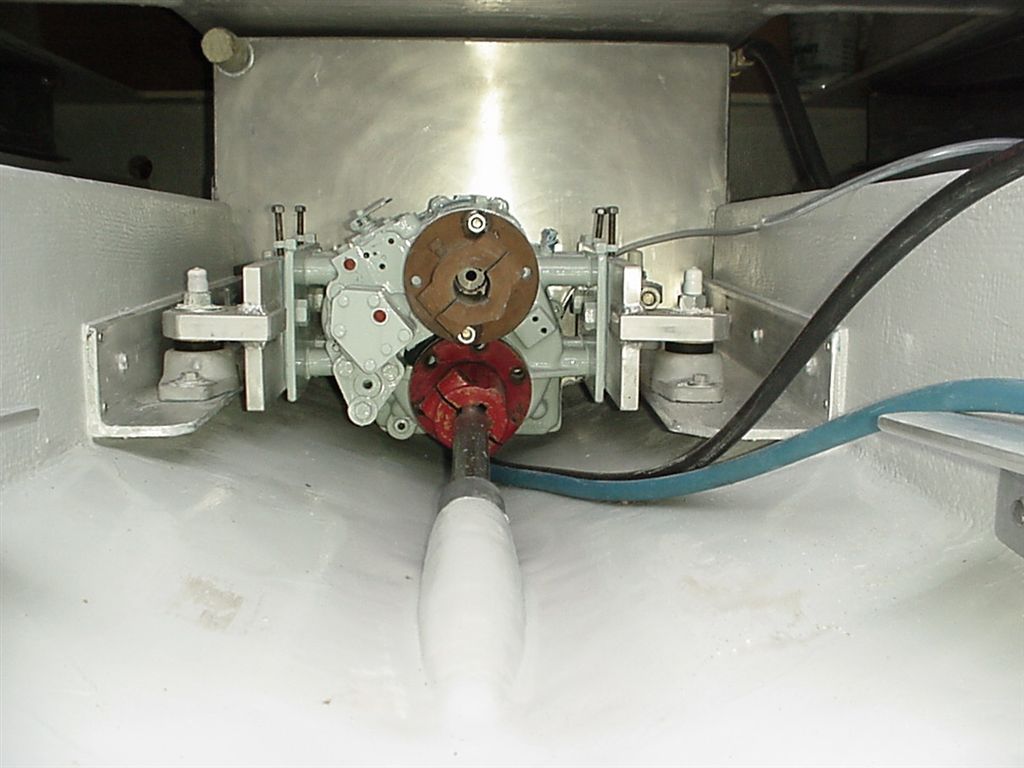

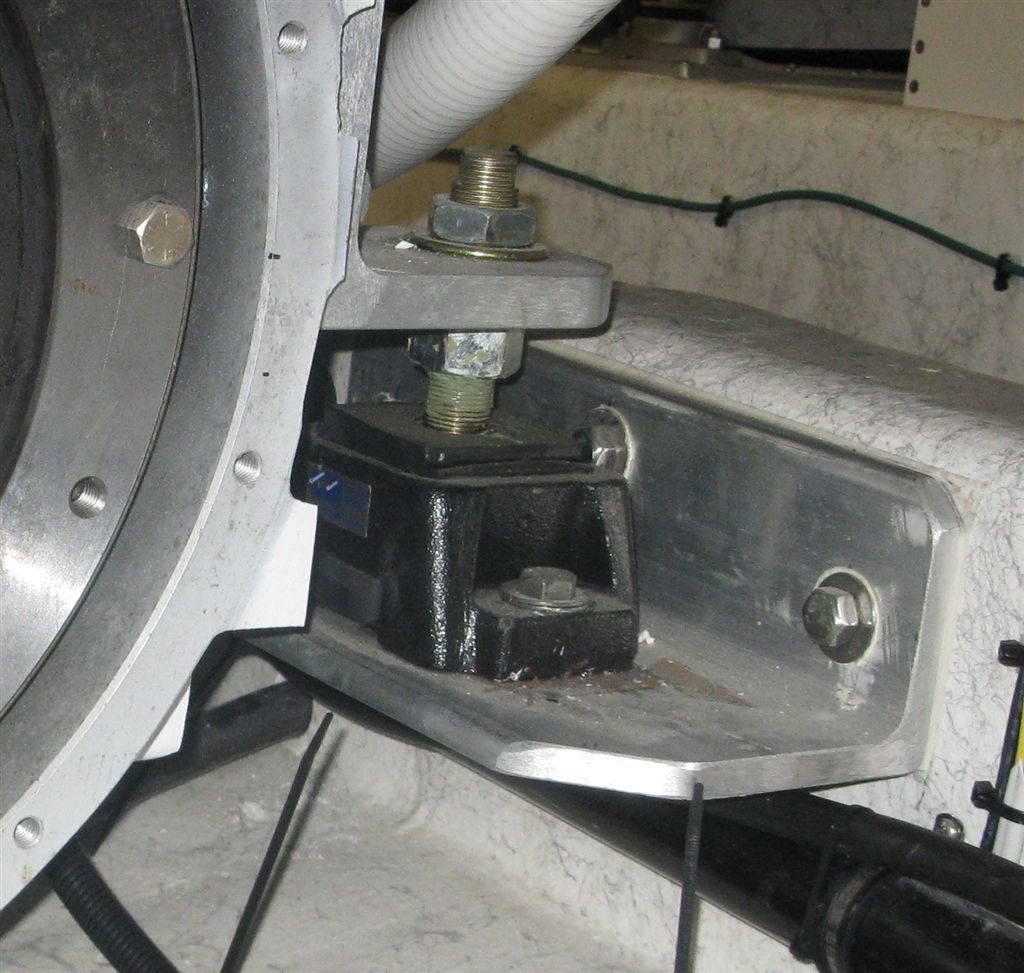

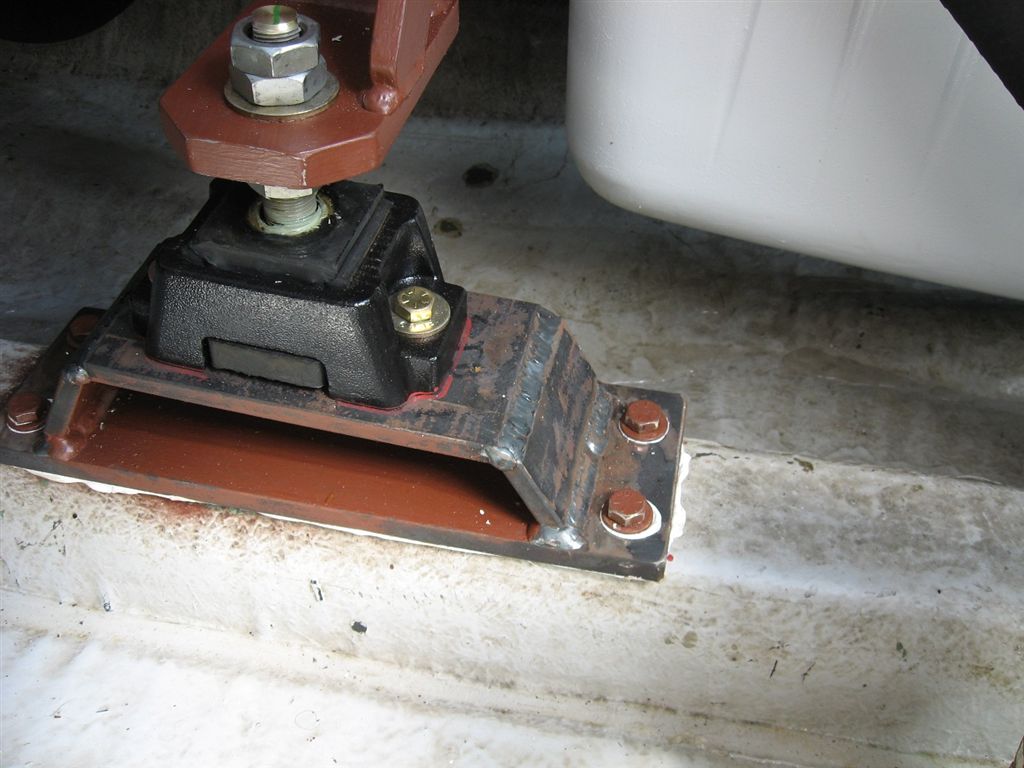

Pull each mount, remove all the nuts, wire brush the studs, grease heavily with a real good grease (Alco Metalube is best) , run the large nut all the way down to the bottom, bring it back up to approx. where the top small nut was, grease all again including both sides of all the washers.. The idea is to eliminate Friction between the surfaces and threads, something the typical engineer has no clue of as all they do is look at numbers.

Now, you can do the alignment. With greased studs you can load the mounts evenly by FEEL. Big nut on the bottom (the couch engineers are 100% wrong on this, as Cummins even knows that now).

Grease and being able to “feel” with close to ZERO friction is the key to easy & even mount loading, regardless of what else you have read…. Grease is also the key to getting that top NUT TIGHT which needs to be right at 200 ft. lbs.++ Only way is you use a custom “short wrench” wrench and a hammer after you have exhausted your 1.25″ open end with an extension… We make our own.