When working in and around your boat, understanding the different fastener thread types can be exhausting! Not only are there many different types of fasteners on your boat and marine diesel engine, each of those fasteners can have different threads… not to worry, the Seaboard team has spent countless hours sorting out all of the different threads and fasteners all compiled in the tables below:

Thread Terminology

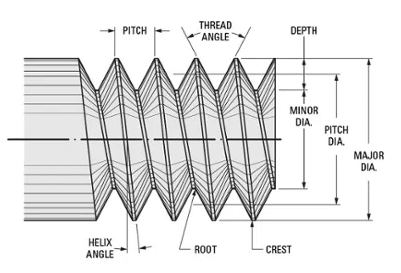

When researching different types of screw threads, you will encounter some basic terms:

When researching different types of screw threads, you will encounter some basic terms:

- Major diameter – In an external thread like the edges of a screw, major diameter refers to the diameter of the overall shaft, including the height of the raised helix. It can be measured on the crests with a calliper rule or slot gauge.

- Minor diameter – Minor diameter measures the diameter of the “root,” or innermost part of the screw, not including the crests of the helix. For accuracy, this measurement requires specialized equipment.

- Effective diameter – The effective diameter is halfway between the major and minor diameters. In other words, it measures halfway up the helix crest. For accuracy, this measurement also requires specialized equipment.

- Pitch – The pitch is the distance between two identical threads.

- Flank – The flank is the angle at which the helix is raised to form a crest on the thread.

- Crest – The crest is the height at which an external thread is raised, or the depth at which an internal thread is indented. For common applications, screws and bolts are measured at the crests, while nuts are measured at the roots.

Using the information above, you will be able to read and understand a screw thread callout when shopping for a replacement.

Identifying Threads

It’s important to identify the specific thread type you need in order for your equipment to function at its best. Pneumatic components such as air cylinders, valves, and air preparation units come equipped with specific port threads. For example, the pneumatic components we offer in our web store are available with either NPT, PT or G port threads.

Choosing the correct thread type will ensure optimum compatibility with your equipment. At a glance, threads may look similar. But take a closer look and you’ll notice the very subtle differences that would make them incompatible with one another. For example, G threads are not compatible with M threads nor NPT threads because of their differing angles, shapes, and thread pitches (threads per inch).

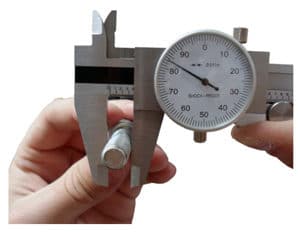

Calipers

A caliper is a useful tool that measures the outside diameter of a male thread and inside diameter of a female thread. Using a caliper will give you the most accurate and precise measurements.

Gender

Every matched pair of threads, external and internal, can be described as male and female. For example, a screw has male threads, while its matching hole (whether in nut or substrate) has female threads. This property is called gender.

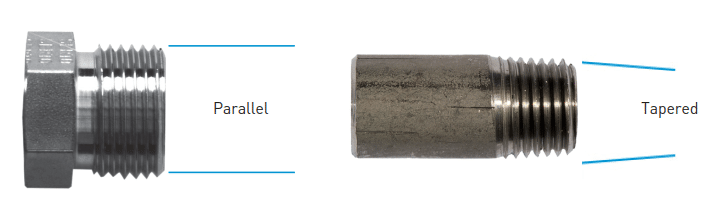

Tapered Threads v. Parallel Threads

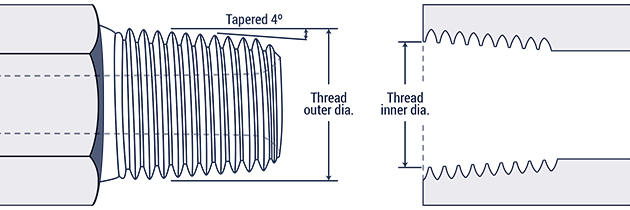

Next, determine if the thread is tapered or parallel. Tapered threads become narrower as they extend outward while parallel threads remain the same diameter. Sometimes this characteristic can be determined through visual inspection, but if not a caliper can come in handy. Use the caliper to measure the first, fourth, and final full thread. If the measurements are all the same, then it’s parallel. If the measurements decrease in size, then it’s tapered.

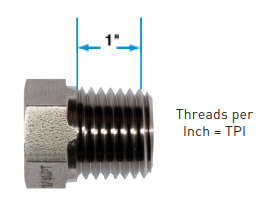

Thread Pitch

The pitch is the distance from the crest of one thread to the next in mm. TPI (Threads per inch) is used by inch thread.

Thread Size Charts

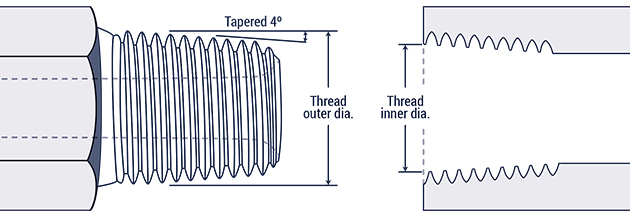

National Pipe Tapered Fuel (NPTF)

The NPTF is a dryseal thread. The male thread mates with the female thread and a seal is formed when the two are crushed together i.e. threads deformation. Teflon and pipe dope are commonly used when additional sealing is needed. Although this connection is widely used in fluid piping systems, the National Fluid Power Association (NFPA) does not recommend it for hydraulic applications.

NB: Although the NPTF connector and BSPT connector are similar in appearance, the two are not interchangeable.

| Inch size | Dash size | Threads per Inch | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 27 | 13⁄32 | 0.41 | 3⁄8 | 0.38 |

| 1⁄4 | -4 | 18 | 17⁄32 | 0.54 | 1⁄2 | 0.49 |

| 3⁄8 | -6 | 14 | 11⁄16 | 0.68 | 5⁄8 | 0.63 |

| 1⁄2 | -8 | 14 | 27⁄32 | 0.84 | 25⁄32 | 0.77 |

| 3⁄4 | -12 | 14 | 1 1⁄16 | 1.05 | 1 | 0.98 |

| 1 | -16 | 11 1⁄2 | 1 5⁄16 | 1.32 | 1 1⁄4 | 1.24 |

| 1 1⁄4 | -20 | 11 1⁄2 | 1 21⁄32 | 1.66 | 1 19⁄32 | 1.58 |

| 1 1⁄2 | -24 | 11 1⁄2 | 1 29⁄32 | 1.90 | 1 13⁄16 | 1.82 |

| 2 | -32 | 11 1⁄2 | 2 3⁄8 | 2.38 | 2 5⁄16 | 2.30 |

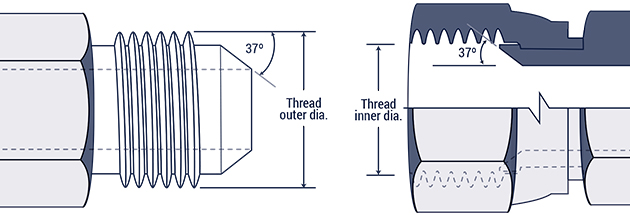

JIC 37° Flare (SAE J514)

This connection finds many applications in hydraulic systems. Both the JIC male and JIC female have a 37º flare seat and straight threads. The male and female flare seats seal when the straight threads are engaged. The connection is held mechanically by the straight threads of the male and female halves. It is important to note that most SAE J514 threads are identical to SAE 45º flare threads but their seating angles are different.

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 5⁄16 – 24 | 5⁄16 | 0.31 | 9⁄32 | 0.27 |

| 3⁄16 | -3 | 3⁄8 – 24 | 3⁄8 | 0.38 | 11⁄32 | 0.34 |

| 1⁄4 | -4 | 7⁄16 – 20 | 7⁄16 | 0.44 | 13⁄32 | 0.39 |

| 5⁄16 | -5 | 1⁄2 – 20 | 1⁄2 | 0.50 | 15⁄32 | 0.45 |

| 3⁄8 | -6 | 9⁄16 – 18 | 9⁄16 | 0.56 | 17⁄32 | 0.51 |

| 1⁄2 | -8 | 3⁄4 – 16 | 3⁄4 | 0.75 | 11⁄16 | 0.69 |

| 5⁄8 | -10 | 7⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.81 |

| 3⁄4 | -12 | 1 1⁄16 – 12 | 11⁄16 | 1.06 | 1 | 0.98 |

| 7⁄8 | -14 | 1 3⁄16 – 12 | 1 3⁄16 | 1.19 | 1 1⁄8 | 1.10 |

| 1 | -16 | 1 5⁄16-12 | 1 5⁄16 | 1.31 | 1 1⁄4 | 1.23 |

| 1 1⁄4 | -20 | 1 5⁄8 – 12 | 1 5⁄8 | 1.63 | 1 9⁄16 | 1.54 |

| 1 1⁄2 | -24 | 1 7⁄8 – 12 | 1 7⁄8 | 1.88 | 1 13⁄16 | 1.79 |

| 2 | -32 | 2 1⁄2 – 12 | 2 1⁄2 | 2.50 | 2 7⁄16 | 2.42 |

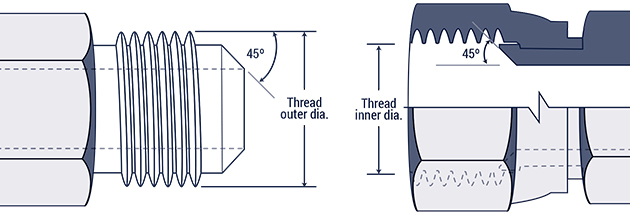

SAE 45° Flare (SAE J512)

The SAE 45° Flare connections are commonly used for low pressure applications such as refrigerant lines, fuel lines, and automotive piping systems. Both the SAE male and female halves have a 45° flare seat. The threads of the two halves engage to form a strong mechanical connection. The seal is formed on the 45° flare seat. Except for the seat angles, the SAE 45° Flare connectors are identical to JIC 37° Flare connectors.

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 5⁄16 – 24 | 5⁄16 | 0.31 | 9⁄32 | 0.27 |

| 3⁄16 | -3 | 3⁄8 – 24 | 3⁄8 | 0.38 | 11⁄32 | 0.34 |

| 1⁄4 | -4 | 7⁄16 – 20 | 7⁄16 | 0.44 | 13⁄32 | 0.39 |

| 5⁄16 | -5 | 1⁄2 – 20 | 1⁄2 | 0.50 | 15⁄32 | 0.45 |

| 3⁄8 | -6 | 5⁄8 – 18 | 5⁄8 | 0.63 | 9⁄16 | 0.57 |

| 1⁄2 | -8 | 3⁄4 – 16 | 3⁄4 | 0.75 | 11⁄16 | 0.69 |

| 5⁄8 | -10 | 7⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.81 |

| 3⁄4 | -12 | 1 1⁄16 – 14 | 11⁄16 | 1.06 | 1 | 0.99 |

| 7⁄8 | -14 | 1 1⁄4 – 12 | 1 1⁄4 | 1.25 | 1 5⁄32 | 1.16 |

| 1 | -16 | 1 3⁄8 – 12 | 1 3⁄8 | 1.38 | 1 9⁄32 | 1.29 |

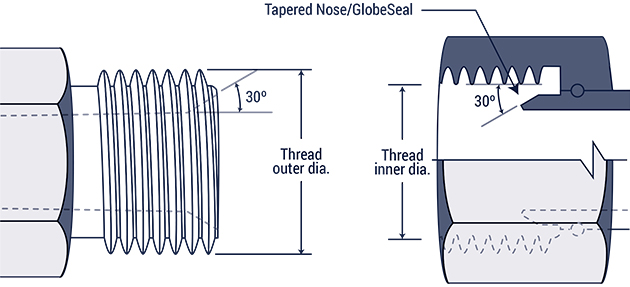

British Standard Pipe Parallel (BSPP)

The BSPP male end has a 300 seat. The tapered nose of the female swivel seals on the 300 seat of the male. Although the male end is similar to the American National Pipe Straight Mechanical (NPSM) male, the two are not interchangeable because their thread pitches are different.

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 1⁄8 – 28 | 3⁄8 | 0.38 | 11⁄32 | 0.35 |

| 1⁄4 | -4 | 1⁄4 – 19 | 33⁄64 | 0.52 | 15⁄32 | 0.47 |

| 3⁄8 | -6 | 3⁄8 – 19 | 21⁄32 | 0.65 | 19⁄32 | 0.60 |

| 1⁄2 | -8 | 1⁄2 – 14 | 13⁄16 | 0.82 | 3⁄4 | 0.75 |

| 5⁄8 | -10 | 5⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.80 |

| 3⁄4 | -12 | 3⁄4 – 14 | 1 1⁄32 | 1.04 | 31⁄32 | 0.97 |

| 1 | -16 | 1 – 11 | 1 5⁄16 | 1.30 | 1 7⁄32 | 1.22 |

| 1 1⁄4 | -20 | 1 1⁄4 – 11 | 1 21⁄32 | 1.65 | 1 9⁄16 | 1.56 |

| 1 1⁄2 | -24 | 1 1⁄2 – 11 | 1 7⁄8 | 1.88 | 1 25⁄32 | 1.79 |

| 2 | -32 | 2 – 11 | 2 11⁄32 | 2.35 | 2 1⁄4 | 2.26 |

British Standard Pipe Tapered (BSPT)

The tapered male of the BSPT mates with a tapered female. The seal takes place on the threads. Although the BSPT male end is similar to the National Pipe Tapered Fuel (NPTF), the two are not interchangeable because their thread form and sizes are different.

| Inch size | Dash size | Thread Size | Male Thread O.D. (in) | Female thread O.D (in) | ||

| 1⁄8 | -2 | 1⁄8 – 28 | 3⁄8 | 0.38 | 11⁄32 | 0.35 |

| 1⁄4 | -4 | 1⁄4 – 19 | 33⁄64 | 0.52 | 15⁄32 | 0.47 |

| 3⁄8 | -6 | 3⁄8 – 19 | 21⁄32 | 0.65 | 19⁄32 | 0.60 |

| 1⁄2 | -8 | 1⁄2 – 14 | 13⁄16 | 0.82 | 3⁄4 | 0.75 |

| 5⁄8 | -10 | 5⁄8 – 14 | 7⁄8 | 0.88 | 13⁄16 | 0.80 |

| 3⁄4 | -12 | 3⁄4 – 14 | 1 1⁄32 | 1.04 | 31⁄32 | 0.97 |

| 1 | -16 | 1 – 11 | 1 5⁄16 | 1.30 | 1 7⁄32 | 1.22 |

| 1 1⁄4 | -20 | 1 1⁄4 – 11 | 1 21⁄32 | 1.65 | 1 9⁄16 | 1.56 |

| 1 1⁄2 | -24 | 1 1⁄2 – 11 | 1 7⁄8 | 1.88 | 1 25⁄32 | 1.79 |

| 2 | -32 | 2 – 11 | 2 11⁄32 | 2.35 | 2 1⁄4 | 2.26 |

ISO 6149 Metric Port and Stud Ends

ISO 261 threads & O-ring seal

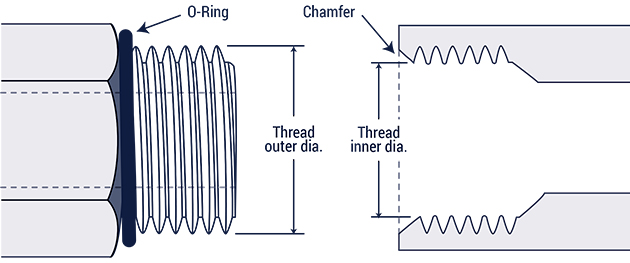

The male connector of the ISO 6149 connection has an O-ring and a straight thread. The female half has a machined surface, a chamfer, and a straight thread. The O-ring on the male sits on the chamfer of the female port. The ISO 6149 connection is similar to the SAE J1926-1O-ring Boss except that the former has metric threads. The O-ring on the male connector is compressed into the chamfer to create a seal. The straight threads engage to form a mechanically strong connection.

| Metric Thread Size | Male Thread O.D. (mm) | Female Thread I.D (mm) |

| M8 x 1.0 | 8 | 7 |

| M10 x 1.0 | 10 | 9 |

| M12 x 1.5 | 12 | 10.5 |

| M14 x 1.5 | 14 | 12.5 |

| M16 x 1.5 | 16 | 14.5 |

| M18 x 1.5 | 18 | 16.5 |

| M22 x 1.5 | 22 | 20.5 |

| M27 x 2.0 | 27 | 25 |

| M33 x 2.0 | 33 | 31 |

| M42 x 2.0 | 42 | 40 |

| M48 x 2.0 | 48 | 46 |

| M60 x 2.0 | 60 | 58 |