“SmartCraft” is a Mercury thing that started with their electronic outboards and is still the backbone of their gas engines & outboards. There have been so many changes and revisions over the years that even the Mercury “lifers” can’t keep up. As to Cummins and SmartCraft, in the early 2000’s Cummins started working with Mercury for some of their first electronically-controlled engines like the 6CTA 8.3 M4, better known as the” 480CE”……………….Then, the big buy-in around 2003-2004 Cummins needed to develop a full line of electronic “marine engines” from the very successful on-road and industrial engines they had (the QSB, QSC & QSL9 platforms) and money for this was short. At the same time, Mercury wanted a line of diesels that they could put their name on, so the marriage was born, CMD or “Cummins Mercruiser Diesel”, with Cummins supplying the engines and Mercury supplying the bucks and electronics….. Well Cummins engines were already 100% full authority electronic engines running on the world standard SAE J1939 CANbus protocol—110% ROCK SOLID and overall a simple system—one twisted pair of data wires going to the dash with 4-8 wires controlling the mechanical or “analog system” of the engine (ignition, start-stop, ground & 12VDC supply, and some spares).

Mercury was not going to reinvent what they had on outboards & gas engines so they “adapted” SmartCraft to work with J1939 by developing an interface known as a SIM or “system integration module”. In so many words, the SIM took the SAE J1939 engine data language standard and converted it to CHINESE or worse with tons of it lost in the translation, along with adding 10X the number of wires, plugs & connections in-between the engine and the helm station. Then as the years went by, the revisions and added complication to the system kept growing—SmartCraft Ver. 1.0, 2.0, 2.2 and what I call it now, 2.X as I have lost track. Plus each revision had revisions within themselves with 1.0 being the real learning curve. But what is so funny, the 1.0 version is still the simplest and the easiest one to troubleshoot, plus the easiest one to dump and go back to “J1939 and common sense simplicity,” when you finally have had it with trying to deal with it and all the glitches that pop up time & time with no one around who can really help.

Well finally Cummins saw the light and a few years ago, they divorced Mercury and started selling factory engines with just J1939 electronics. Yes, SmartCraft is still available but at least you have the option so that you do not have to pay for it.

So here we are today—————————

The crazy MESS that is SmartCraft…

Look at the following video to get an idea about how many wires and components are involved with a SmartCraft instrumentation system for your Cummins Marine engine:

The Solution and better Alternative to Mercury SmartCraft

At Seaboard Marine, the solution and better alternative to using the Mercury instruments is to stick to the basics… that means leveraging the native signal the engine already produces that is also used on every on-road vehicle produced today. That signal is the SAE standard J1939 CANbus data protocol. The simplicity lies in the fact that all of the engine data, faults, alarms, etc. is transmitted on a single twisted pair of wires that will be run from the engine interface to the dash display. The SMX instrument systems we use in house for ALL of our new engine sales uses at a minimum, 7 wires to both display data and start/stop the engine in total which reduces the potential for system glitches caused by physical wiring issues, etc. In addition, if system issues were to occur, the troubleshooting process becomes much easier as there are way less areas to assess as failure points. With over 200+++ systems in the field, we feel confident that our simplified systems work well for all types of instrumentation implementations including but not limited to recreational, commercial, and even government vessel applications.

At Seaboard Marine, the solution and better alternative to using the Mercury instruments is to stick to the basics… that means leveraging the native signal the engine already produces that is also used on every on-road vehicle produced today. That signal is the SAE standard J1939 CANbus data protocol. The simplicity lies in the fact that all of the engine data, faults, alarms, etc. is transmitted on a single twisted pair of wires that will be run from the engine interface to the dash display. The SMX instrument systems we use in house for ALL of our new engine sales uses at a minimum, 7 wires to both display data and start/stop the engine in total which reduces the potential for system glitches caused by physical wiring issues, etc. In addition, if system issues were to occur, the troubleshooting process becomes much easier as there are way less areas to assess as failure points. With over 200+++ systems in the field, we feel confident that our simplified systems work well for all types of instrumentation implementations including but not limited to recreational, commercial, and even government vessel applications.

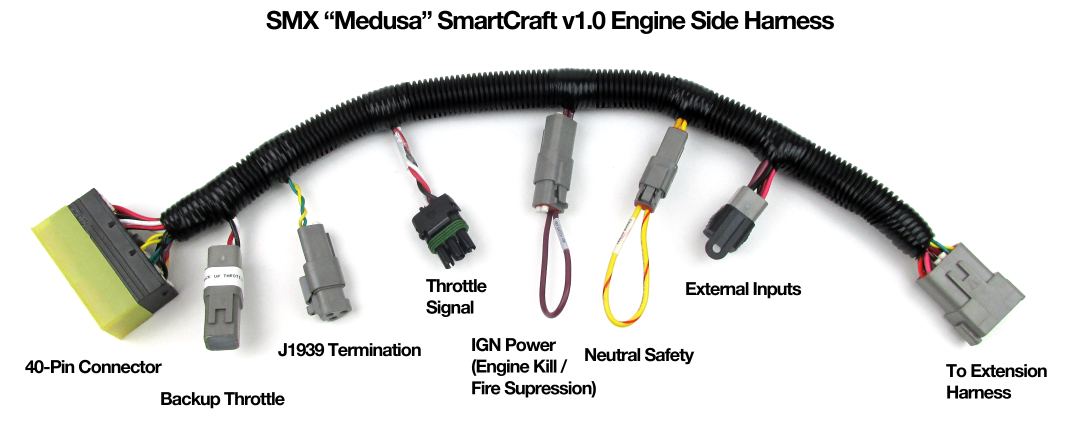

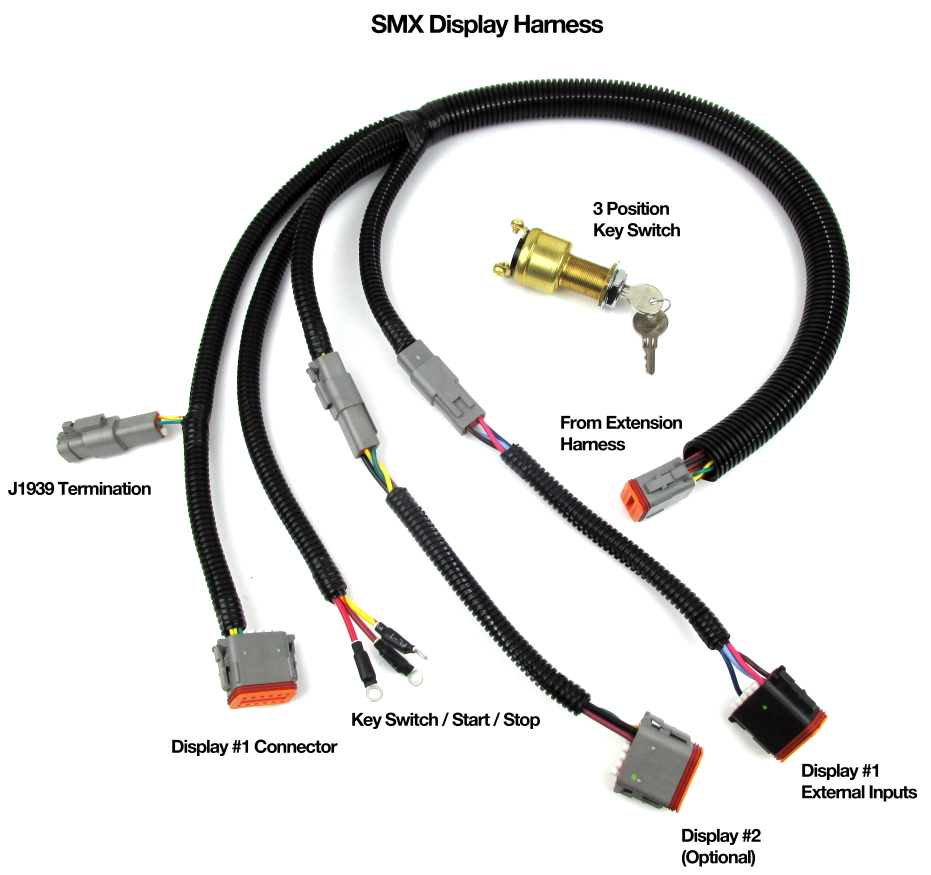

The SMX instrumentation system is setup in a very simple way with the following 4 major components: