Article By: Rob Schepis

Much too often on the boating technical forums the questions are asked about installing zincs and the risk of using a pipe dope. The concern is that anything other than clean bare threads may “impede” a good electrical connection between the zinc cap and the body of the cooler in which it is being installed, thus rendering the zinc less effective or totally ineffective. I recently came across this on a boat builder’s website as well which prompted me to do this write up and pictorial.

Let’s understand the zinc cap design and look at the benefits of using a pipe dope before we get to whether or not it actually has an ill effect on the electrical connection.

The zinc cap threads into the casting, the cooler body or, in some cases, a cooler’s end cover. The threads are commonly referred to as pipe thread, abbreviation “NPT” for national pipe taper. It is the taper of the threads that creates the sealing pressure (a.k.a. interference fit) as the male component is tightened within the female component. Once tightened, the interfering threads create the seal. This is unlike the straight thread where the male component (bolt) spins without resistance into the female component (nut).

For that tapered thread interference fit to be 100% leak free it would have to be machined perfectly (zero-tolerance) and be absolutely free of any defects, burrs, bumps, etc. This is not the case in the real world. The use of a pipe dope has multiple benefits. It fills any machining or “after-machining” voids or imperfections that could and will leak. By sealing the threads, it also keeps out external impurities that would cause corrosion, much like the use of a dielectric compound on an electrical connection. And lastly, it also lubricates and prevents thread galling (seizing). The lubricating benefit is important on both assembly and disassembly.

Now we should be that much clearer as to how the pipe threads function and the benefits of using a pipe dope to seal, preserve and lubricate the threaded connection.

For the purpose of installing zincs, we need to investigate the electrical effect of the pipe dope on that threaded connection. Does it totally, or partially, effect the connection in the form of blocked current flow or added resistance? Does it have zero effect on the current flow through the threaded connection with no added resistance?

Preferring to do this on the bench, rather than in the boat’s engine room, I utilized a common 1/2″ NPT zinc cap and a brass check valve casting. The valve body casting simulates any engine component that the zinc would be threaded into.

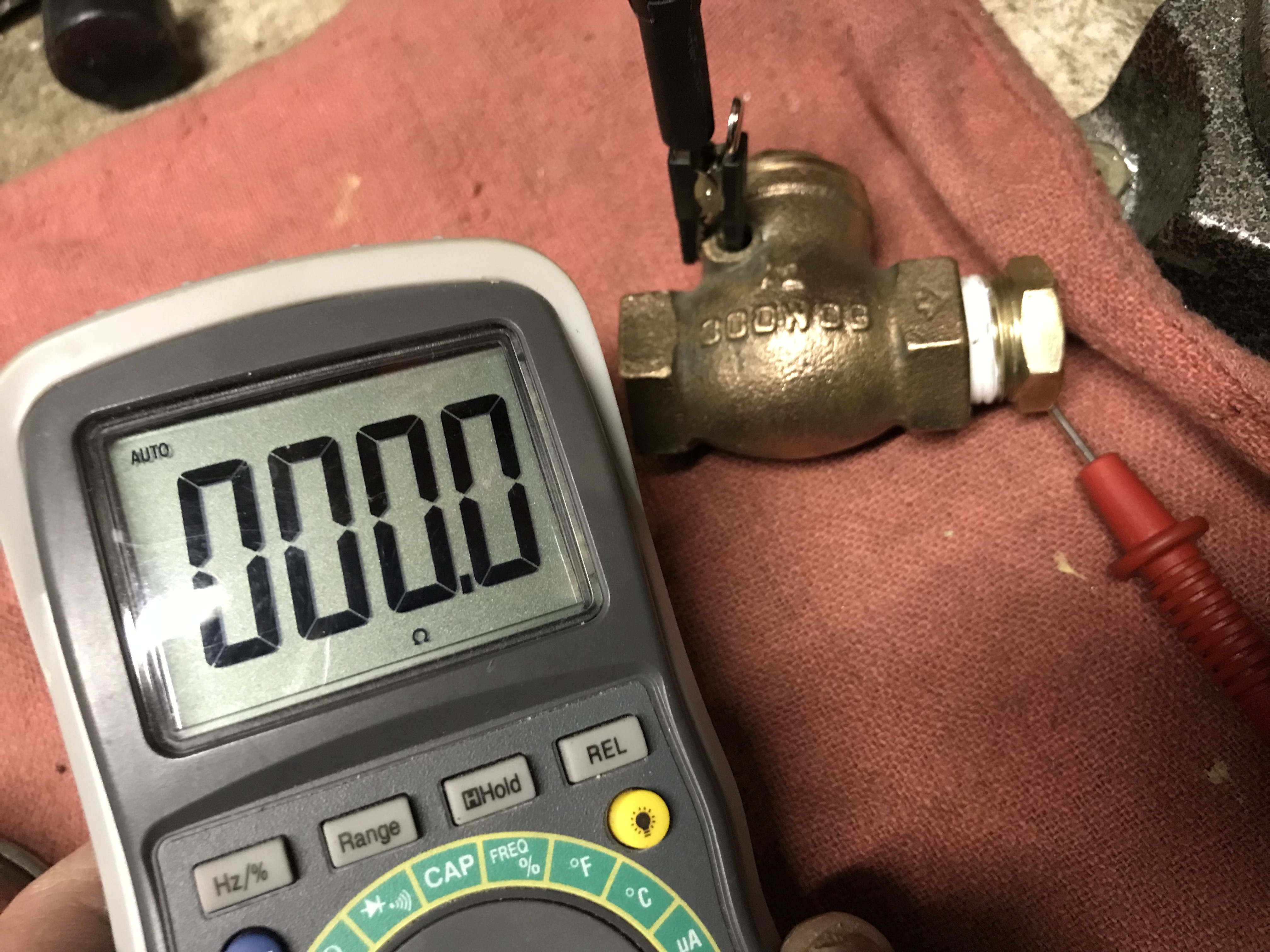

Photo (01) shows infinite resistance with an open connection at the meter leads.

As expected, Photo (02) shows zero resistance when the bare cap is threaded into the casting.

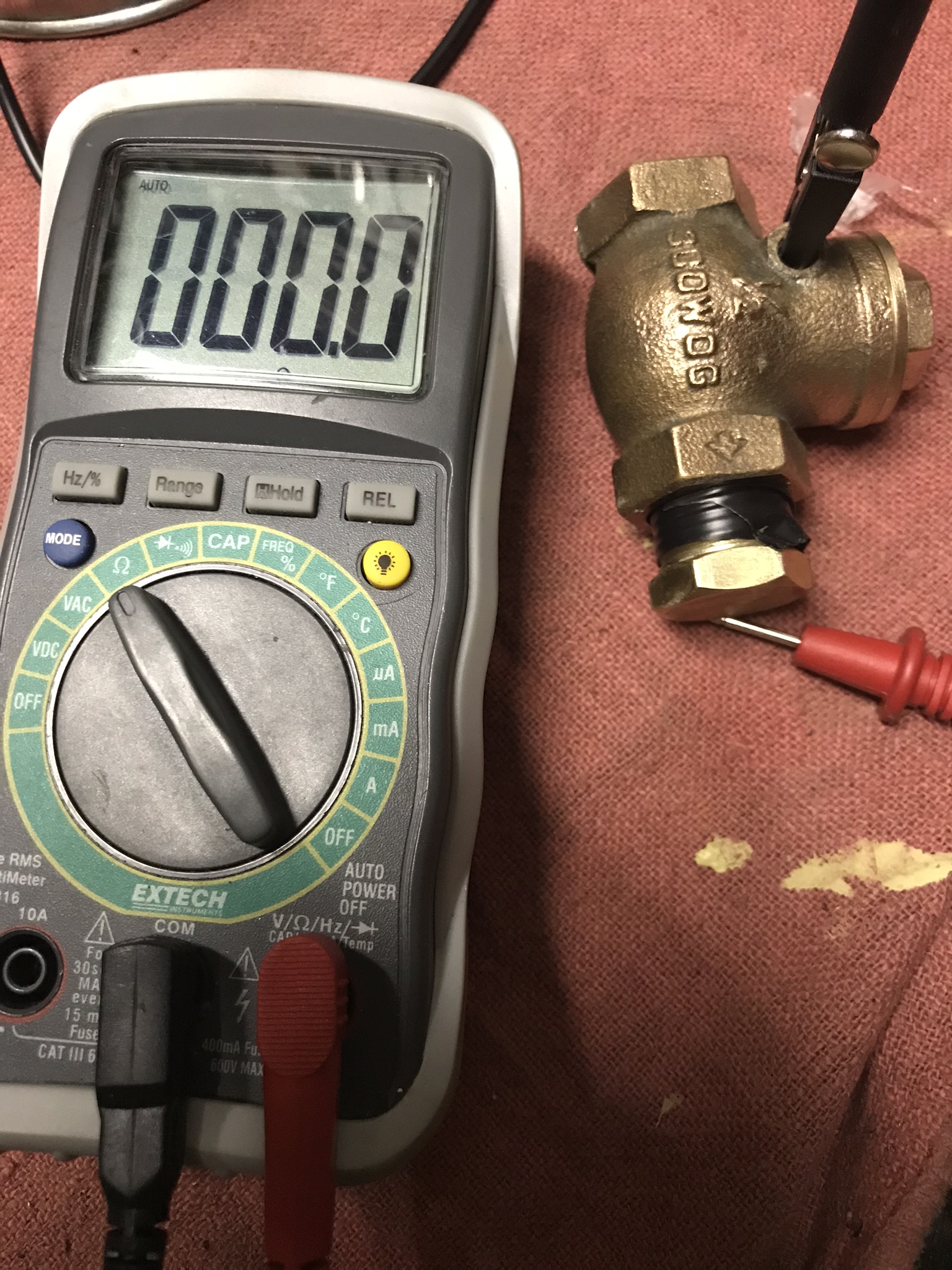

Some folks prefer teflon tape over pipe dope since it’s cleaner to work with. Photos (03) and (04) show zero resistance when teflon tape is used to lubricate and seal the threads.

Next is the pipe dope. A popular product is Rectorseal 5. Photos (05) and (06) show zero resistance when this pipe dope is used to lubricate and seal the threads.

It is not unheard of for plumbers to use a combination of teflon tape and pipe dope. This is mostly done on a problem connection that is being difficult as to making it leak free. Yes, zincs are cheap and easy to replace, but what if your cooler or end cover threads are not in good shape and cleaning them up with a tap still results in a weeping zinc. Over-tightening will only compound your problems. The tape & dope combination may need to be considered. Well have no fear, Photos (07) and (08) show zero resistance when a teflon tape & pipe dope combination is used to lubricate and seal the threads.

For fun taking this one step further, Photos (09) and (10) show zero resistance when several wraps of vinyl electrical “insulating” tape is applied to the threads.

The reason that neither of these products applied to the pipe threads caused any resistance is that the metal to metal contact is not in any way prevented or inhibited. The pipe dope or teflon tape only fills the voids where there is no metal to metal contact and it is those voids that would otherwise leave you with a leaky connection.