Blow by Measurement

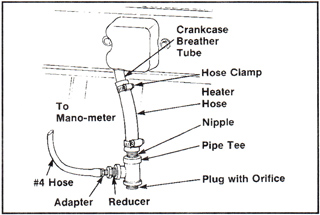

Blow by is generally recorded in liters per minute, but a water manometer may be used to measure blow by from the breather tube after fabricating the following adaptation:

Blow by is generally recorded in liters per minute, but a water manometer may be used to measure blow by from the breather tube after fabricating the following adaptation:

- Plug the end of the straight portion of a pipe tee

- Drill an orifice in the plug (refer to the Blow by Conversion Chart below for the appropriate orifice size)

- Connect the open straight portion of the pipe tee to the breather tube

- Connect a water manometer to the 90 degree outlet

- Use the Blow by Conversion Chart to convert the manometer reading to liters/minute

| Blow by Conversion Chart (5.613 .mm [0.221 in] Orifice) | |||

|---|---|---|---|

| Inches of Water | Liters/Minute | Inches of Water | Liters/Minute |

| 1 | 27 | 19 | 121 |

| 2 | 40 | 20 | 124 |

| 3 | 49 | 21 | 128 |

| 4 | 58 | 22 | 131 |

| 5 | 64 | 23 | 135 |

| 6 | 71 | 24 | 137 |

| 7 | 76 | 25 | 140 |

| 8 | 81 | 26 | 144 |

| 9 | 86 | 27 | 147 |

| 10 | 90 | 28 | 150 |

| 11 | 94 | 29 | 154 |

| 12 | 98 | 30 | 157 |

| 13 | 102 | 31 | 160 |

| 14 | 105 | 32 | 163 |

| 15 | 109 | 33 | 166 |

| 16 | 112 | 34 | 169 |

| 17 | 115 | 35 | 170 |

| 18 | 118 | ||

Engine Testing – General Information

The engine test is a combination of an engine run-in and a performance check. The engine run-in procedure provides an operating period that allows the engine parts to achieve a final finish and fit. The performance check provides an opportunity to perform final adjustments needed to optimize tho engine performance. An engine test can be performed using either an engine dynamometer or a chassis dynamometer, If a dynamometer is not available, an engine test must be performed in a manner that simulates a dynamometer test.

Check the dynamometer before beginning the test. The dynamometer must have the capability to test the performance of the engine when the engine is operating at the maximum RPM and horsepower range (full power).

The engine crankcase pressure, often referred to as engine blowby, is an important factor that indicates when the piston rings have achieved the correct finish and fit. Rapid changes of blowby or values that exceed specifications more than 50 percent indicate that something is wrong. The engine test must be discontinued until the cause has been determined and corrected.

General Engine Test Specifications

Maintain the following limits during a chassis dynamometer test:

| Intake Restriction (Maximum) | ||

|---|---|---|

| Clean Filter | (light duty) | 254 mm H2O [10 in. H2O] |

| (medium duty) | 305 mm H2O [12 in. H20] | |

| (heavy duty) | 381 mm H2O [15 in. H2O] | |

| Dirty Filter | (light duty) | 635 nm [25 in] |

| (medium duty) | 635 nm [25 in] | |

| (heavy duty) | 635 nm [25 in] | |

| Exhaust Back Pressure (maximum) | ||

| Industrial | 76 mm Hg [3.0 in.Hg] | |

| EPA Certified | 144mm Hg [4.5 in. Hg] | |

| Oxidation Catalyst | 152mm Hg [6.0 in. Hg] | |

Blow by** (at Given Speed, 100% Load)

| Engine | New (L/Min.) | Worn (L/Min) |

|---|---|---|

| 4B @ 2200 | 18 | 36 |

| 4B @ 2500 | 20 | 40 |

| 4B @ 2800 | 23 | 46 |

| 4BT/4BTA/B3.9 @ 2200 | 45 | 90 |

| 4BT/4BTA/B3.9 @ 2500 | 51 | 102 |

| 4BT/4BTA/B3.9 @ 2800 | 57 | 114 |

| 6B @ 2200 | 26 | 52 |

| 6B @ 2500 | 30 | 60 |

| 6B @ 2800 | 34 | 68 |

| 6BT/6BTA/B5.9 @ 2200 | 63 | 126 |

| 6BT/6BTA/B5.9 @ 2500 | 76 | 152 |

| 6BT/6BTA/B5.9 @ 2800 | 85 | 170 |

| **Blow by Checking tool, Part No. 3822476, has a special 5.613 mm [0.221 in.] orifice that bust be used to get an accurate reading. | ||

Oil Pressure

| Low Idle (Minimum Allowable) | 69 KPa [10 psi] |

| Rated Speed (Minimum Allowable) | 207 KPa [30 psi] |

| * Fuel Filter Restriction (Maximum) | |

|---|---|

| Dirty Filter | 35 Kpa [30 psi] |

| Fuel Filter Restriction (Maximum) | 518 mm Hg [20.4 in hg] |

NOTE: Due to variations in ratings of different engine models, refer to the specific engine data sheet for the particular engine model being tested.