Most all of the transmissions on the market transmit their power through sets of multiple disk clutches cooled and lubricated by oil. The disks are pressed together by a piston with pressurized oil providing the force necessary to create enough friction between the disks to prevent slippage. In this non-slipping mode, friction between the disks is transmitting 100% of the input power.

A trolling valve is an adjustable pressure-regulating device incorporated in the hydraulic system of the transmission that allows the pressure to be regulated between 0 and full operating pressure (typically between 250 and 400 PSI). In the trolling mode, you reduce the pressure to allow slippage between these multiple disk clutches/plates and now, this multiple disk “friction clutch” becomes a multiple disk “oil shear clutch”. Most transmissions have very strict guidelines when using the trolling mode and these typically advise not to use them above 1000 rpm or so. Most “trolling” takes place between 25 and 75 PSI. During the trolling mode, there is a small oil film between these clutch disks and in theory the slippage that occurs is actually just shearing oil between two rotating surfaces. Excess oil is pumped to these clutch disks and the heat that is generated during this slipping process is transmitted into the oil and dissipated through the cooling circuit of the transmission. Oil shear clutches are very popular in many different industries and when used according to the guidelines, offer long-term no-maintenance performance. Should you exceed rated rpms, major damage can occur very quickly, as the oil film (or shearing process) will break down and cause extreme wear and heat within the disks themselves.

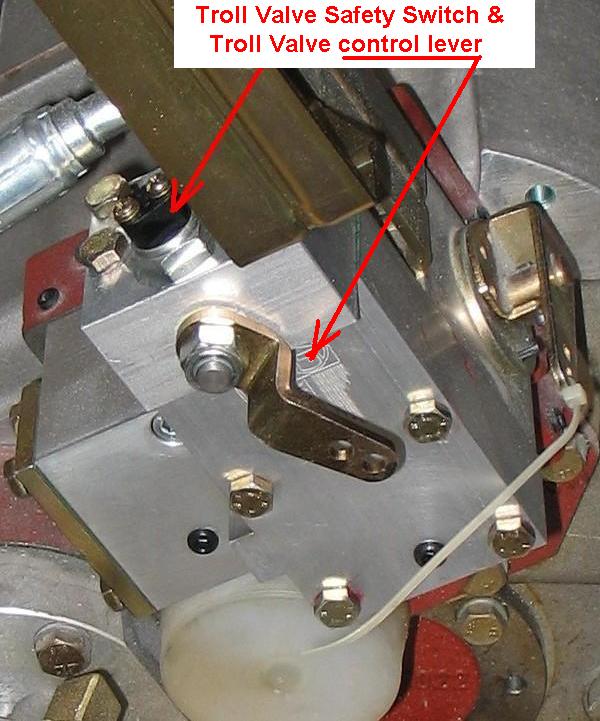

The cost of a trolling valve seems cheap initially ($600 to $1,000), but the proper installation and control linkage that one needs to make the system usable and reliable can add hundreds of dollars to this cost. A very smooth operating control cable and level system is necessary along with an accurate pressure gauge in order to adjust the pressure to slip the clutches… A safety device is also handy to make the operator remember that “he’s in the trolling mode”, thereby preventing damage to the transmission.

A few words of caution and wisdom about trolling valves. The cost of the valve is not bad (About $700 ea), but it’s a full proof installation/operation system on the boat that can get pricey.. At the very least you’ll need both trannies w/ valves, and you’ll need accurate/safe and very readable pressure gauges at the operation station to see what the pressure is. Typical “slipping” pressures are in the 5-40 PSI range and are VERY sensitive to a few PSI one way or the other.. I use a 0-400 fluid filled high quality mechanical gauge with a “back fitting” and very high quality hose and fittings to reach the dash. You’ll need a VERY accurate and adjustable control cable system as the slightest movement of the control lever on the trans will move the pressure between slip and no slip. You should also install a warning system to prevent you or someone from advancing the throttles past 1000 RPM when in the trolling mode.. If you spend the time and $$ to do it right, they work (even on a light weight boat). But don’t forget that it only takes once or twice to destroy a clutch pack if one forgets about “the trolling mode”, and punches it……….