Signs that your boat is over-propped or over-loaded

Are you experiencing engine performance issues? Do your engines seem old and tired and not as “spunky” as they used to be? Are your engines pluming black smoke when trying to get up on plane? Can’t reach the governor break point RPM (NOT RATED RPM) of the engine at wide open throttle (WOT)?

There’s a good chance that your engines may be suffering from an over-loading condition which is more common that it should be in the marine diesel world. Regardless of why, being overloaded is directly related to the propeller matching the vessels current running configuration, weight, vessel bottom condition, windage, or running gear issues/conditions, but all of these go back to the prop as they all make the engine work harder because of these conditions, and slow the vessel down overloading the engine. Also, remember the term “external to the engine” as you read further.

Why is engine over-loading so prevalent?

Think back to the day the boat was first splashed… nice clean hull, spotless bottom paint, perfect propellers, and brand new never used marine diesel engines just ready to burn fuel and send the boat off at 30-40+++ knots. You’re SO impressed at the awesome performance of the boat (and so is the salesman $$$). Now, fast forward to 1000; 2000; 3000+++ engine hours later. Ask yourself these questions… has the boat gotten any lighter? Has the bottom gotten any cleaner? Have the props remained in near perfect condition? Have the engines been serviced meticulously per the proper maintenance protocols? Have you added any additional windage to the boat? All these components will consume available horsepower from the engines… and the engines will deliver the additional fuel you are requesting to keep the boat travelling the same speed as it did on seatrial day. Only problem is the additional fuel needed to now move the boat the same speed that it did on seatrial day years ago is probably more than what the engine designers and manufacturers originally designed the engine to burn to achieve your desired speed. Once you go above and beyond the recommended fuel burn at RPM, the additional heat and “wear & tear” on the engines over time will begin to start creating “issues”. As you try to address the issues, new ones will appear over time and create a very frustrating circular troubleshooting process. Until the root cause is remedied, these issues will only get worse and cause more frustration.

Engine loading

The propeller(s) are what move the boat and are what provide LOAD to the engine(s). The bigger the propeller and amount of pitch, the more LOAD is imparted to the engines. The other critical factors that will add load to the engines is the overall WEIGHT of the boat, bottom conditions, windage, and any other related items that create DRAG. The most significant part of the entire equation of vessel/diesel engine operation leading to long engine life starts with the way an engine is propped (loaded) during normal vessel operation (not during a boat sale “sea trial”). This is number one, but add to this that the average diesel boat operator or new boat buyer does not have a true understanding of the (his) application and engine loading in relationship to the engine that is installed in the boat… this is now the formula for premature engine failure. This is not because the vessel operator is “dumb,” he just has not been properly educated this way.

The real tests to determine if you’re over-loaded

1. Governor break point RPM

The easiest test to determine if your engines are being over-loaded is to take the boat out and run the boat at 100% throttle to see if the engines can achieve the “Governor break point RPM”. This test is universal in that you do not need to evaluate the fuel burn in order to determine an over-loading condition. The governor break point RPM will be different for mechanical engine than it will be for electronically controlled engines. See the chart below to evaluate the existing lineup of Cummins Marine RECON engines, if your engine cannot meet the minimum propping target RPM in the chart below, then either the engine performance needs to be assessed (ensuring full throttle lever travel, tach accuracy, full fuel stop solenoid travel, ruling out air/fuel restriction, etc. – See Low Power Troubleshooting) OR propeller PITCH needs to be reduced.

| Engine | BHP-MHP | Minimum Rated RPM | Min Propping Target RPM* |

| 4BT | 150/155 | 2800 | 2900 |

| 210/220 Diamond | 210/220 | 2600 | 2700 |

| 270 Diamond | 260/270 | 2600 | 2725 |

| 315/330 Diamond | 315/330 | 2800 | 2925 |

| 355/370 Diamond | 355/370 | 3000 | 3125 |

| 430/450 Diamond | 430/450 | 2600 | 2725 |

| QSB 380 | 375/380 | 3000 | 3085 |

| QSB 480 | 472/480 | 3400 | 3485 |

| QSC 600 | 593/600 | 3000 | 3085 |

| QSC 500 | 493/500 | 2600 | 2685 |

| WET QSM11 | 450/455 | 2100 | 2150 |

| QSM11 | 661/670 | 2300 | 2350 |

*Or 90% LOAD (or less) at minimum rated RPM.

2. Review and plotting of engine performance against the engine performance curve

For electronically controlled engines, this process is much easier as obtaining the horsepower used is easy to determine by using the instantaneous fuel burn parameter from the digital displays. Once you’re able to easily review the fuel burn at each RPM interval, you can begin the plotting process. First note, your fuel burn rate (g/h) at each 200 RPM interval while on the vessel and then plot your points onto the FUEL CONSUMPTION portion of the Cummins Marine Performance curve.

You can lookup the curve for your engine here: Performance Curves

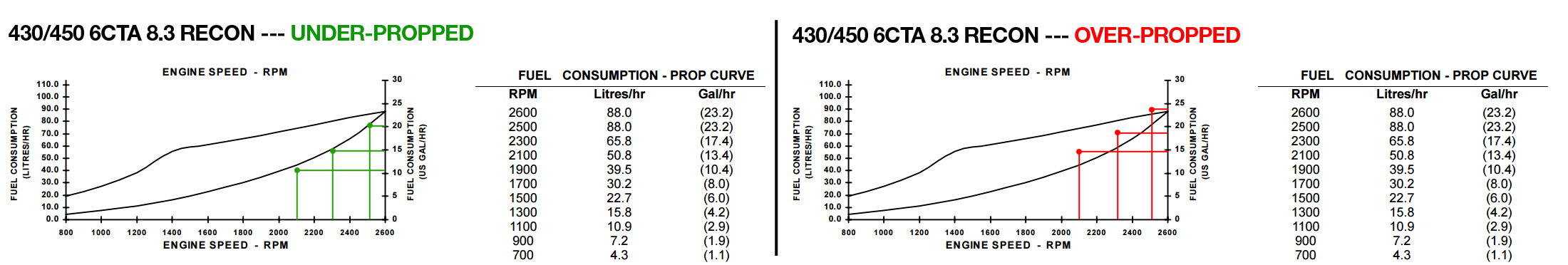

Here is an example of two different engines, one loaded correctly (GREEN) and one that is grossly over-propped (RED)

| 430/450 6CTA 8.3 RECON — UNDER-PROPPED | |

| RPM | Fuel Burn (g/h) |

| 2100 | 11.8 |

| 2300 | 14.7 |

| 2500 | 21.3 |

| 430/450 6CTA 8.3 RECON — OVER-PROPPED | |

| RPM | Fuel Burn (g/h) |

| 2100 | 14.6 |

| 2300 | 18.8 |

| 2500 | 24.2 |

Corey Schmidt