Time for a class in “Fuel Solenoids 101”

1) Grab your old solenoid and get a 12V battery & some 12 AWG test leads — Go to your bench.. .. Cut the Black wire off the plug ( as close to the plug as possible) and install a GOOD 1/4″ Heavy duty ring terminal on the end.. This is now PERMANENT and IMO, you should do the same on the other engine… This is the common ground for the TWO INTERNAL coils inside the solenoid and goes under the mounting bolt on the solenoid bracket when mounted to the engine–This makes for a SUPERIOR ground with less voltage/current drop.

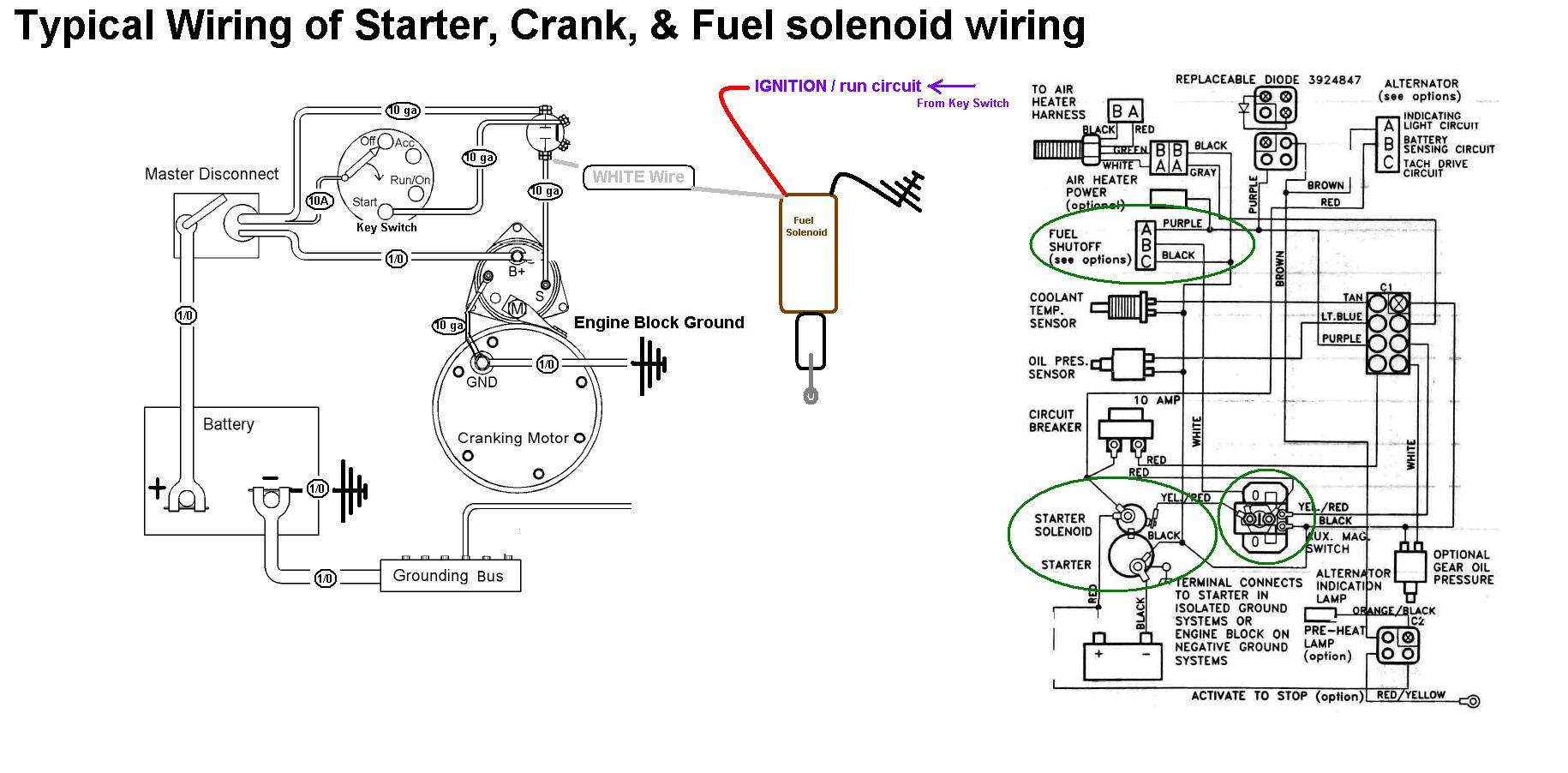

2) Now, let’s LEARN how your solenoid works.

1st, ground the black lead (12V NEG)… 2nd, Put 12V POS to the RED lead—you’ll “see” a 1 amp spark when you do it, but that is all… Now, with those leads connected, PUSH the solenoid in to the “HOLD” position… This is what keeps your engine running and HOLDS the injection pump fuel lever in the RUN POSITION. This runs off the engines IGN circuit… The solenoid, in this mode uses about 8-12 watts of power and over a few hours will heat up to about 120-160F sitting on a bench overnight. The solenoid will hold in this position until power is disconnected. Undo a lead, a see what happens…

Now, let’s keep the GND connected and put power to the WHITE lead… WOW is what you will say as now that “coil” inside the solenoid in trying to use over 20 AMPS, and that is a BIG spark! The solenoid will suck in and hold there until YOU break power, if you make a solid connection. This is a very short intermittent use “coil” and is only designed to stay energized while the engine is trying to crank/start—very few to maybe 30 seconds at a time…

So now, YOU NEED to understand how the system works as explained above, and when you do, YOU will now understand what your issue is… To me it is too simple and easy for ALL to figure out…