With the introduction of electronic control systems, the load demand on an engine is readily displayed and should be used to determine the appropriate propping of the vessel. An electronically controlled engine is able to determine the load placed upon it by using the inputs of engine speed and fueling required to achieve that engine speed. The load reading is displayed as the percentage of load placed on the engine compared to the full load capability of the engine at any given speed. For example, if an engine can produce 200 HP at 2000 rpm and there is a 100 HP draw upon it at 2000 rpm, it would be at 50 percent load. If the same engine can produce 300 HP at 3000 rpm and there is a 270 HP at 3000 rpm draw on it, the load would be 90 percent.

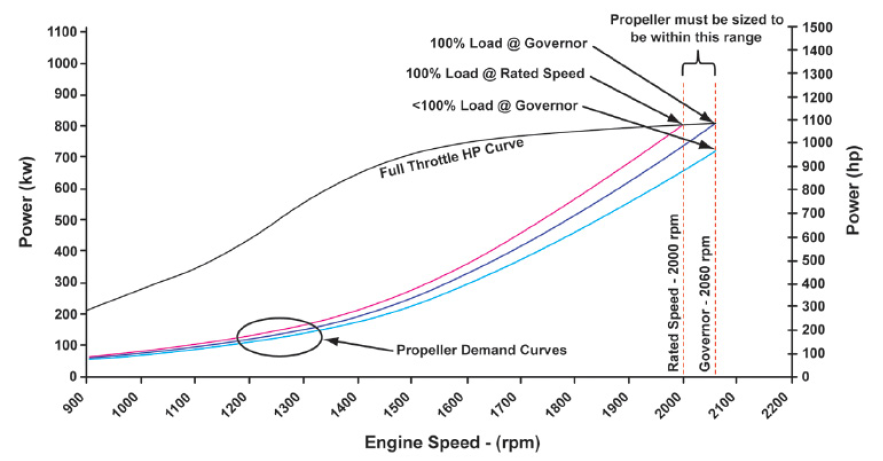

During transient conditions such as hard acceleration, the engine can be at or near 100 percent load demand at less than rated speed. However, once 100% load is reached at steady state conditions, the engine will no longer be able to increase speed. Therefore, if an engine reaches a steady state 100 percent load before rated speed is achieved, it is over-propped. Conversely, if an engine is able to exceed rated speed, the load percentage will indicate less than 100 percent load at rated speed. The degree of under-propping will determine at what speed above rated speed 100% load is achieved.

Electronic engines have an isochronous governor which limits the maximum speed to a range typically between 50-75 rpm above rated speed. Once an engine reaches the governor, it will no longer advance in speed or power. Therefore, if a vessel is sufficiently under-propped so that an engine does not reach 100 percent load before the governor, the engine will be limited from producing all its available power. In some applications, it may be necessary to prop the vessel so that the engines are hitting the governor and not at 100 percent load at full throttle. Typically this applies to production vessels, where the first hull has been loaded to a heavy displacement, tested to comply with reaching rated speed, and then unloaded to conclude what subsequent sister vessels should be propped to when tested light. The resulting prop demand at a light condition may enter the range where the engine speed is limited at the governor and load is less than 100 percent.

Note: CMD electronic engines are designed to produce constant power between rated speed and the

governor speed.

It is Cummins Inc. recommendation that the ideal propping point is to achieve 100 percent load at the governor speed. Typically this will yield a load of 92-95 percent at the rated speed. This maximizes performance, efficiency, and durability of the engine.

Figure 16-1 provides a sample engine performance curve for an electronic engine overlaid with propeller demand curves that graphically depict the above.