Description

- Exclusive design for 100% “PLUG & PLAY” seawater pump replacement on all Cummins QSB 5.9 and the new QSB 6.7 Titan models

- Emergency lube zerk fitting – normal service requirements are one “pump” per 200-300 hours, standard marine grease

- “Off the shelf” bearings and seals – nothing proprietary

- Backed up by an exclusive 24 month “no hassle” pump exchange policy

Some facts & history about our new pump and how it all started…

The seawater pump for the Cummins QSB marine diesel engine was derived from the Sherwood/Cummins 17XX design that was first produced about 1988-1989 and used on the Cummins 6BTA 5.9 300B’s.

Since it’s inception, many similar pumps based on that design have been developed, and all share most all of the same design features.

The only significant differences in the pumps are mainly to the front of the pump and how it mounts to the particular engine or how it is driven (different gear shapes / sizes, and in the case of a QSB, it’s “belt driven”). All have the same shaft diameter, same seal designs, same bearings, same cam and wear plate designs, same base housing, and, as all of the 1000’s of pump owners have learned over the years, all share the same early failure issues.

When we took on the challenge of building a better pump to replace the very popular Sherwood 1730 in 2005, we knew it would be a major project for us. Now with close to 2500 working pumps in the field, we have proved without a doubt, that our SMX design offers superior performance and longevity for the boat owner. About four years ago we looked at building a replacement pump for the new Cummins QSB 5.9 marine diesel engine and we are now happy to say that we have our new SMX-QSB seawater pump available, and in full production. Plus, now that the new Cummins QSB 6.7 Titan is here, we are 100% sure that our pump will also be the perfect upgrade for it as well.

Since the Sherwood/Cummins QSB pump was designed not to long ago (2005), Sherwood has already made not less than 4 major re-designs with the shaft, front hub, seal, and impeller. After building this same basic pump now for over 20 years, just ask yourself why these design changes are continuously being made. As a Cummins dealer for over 25 years we see pump failures on just about every engine we sell that uses this pump, long before warrantee is over. The answer is simple to us, as a pump designer and manufacturer, the base design is flawed and their designers are merely applying band-aid “fixes” trying to solve the problems. So, the question now becomes as a vessel owner, do you want to continue taking chances with the OEM designs when you understand that seawater flow is really the “life blood” of your engine’s cooling system? To us, and the 100’s of Cummins engine owners that have made the change, that answer is now “crystal clear”.

What makes our SMX QSB pump a superior product?

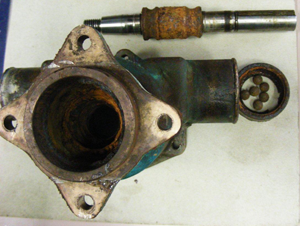

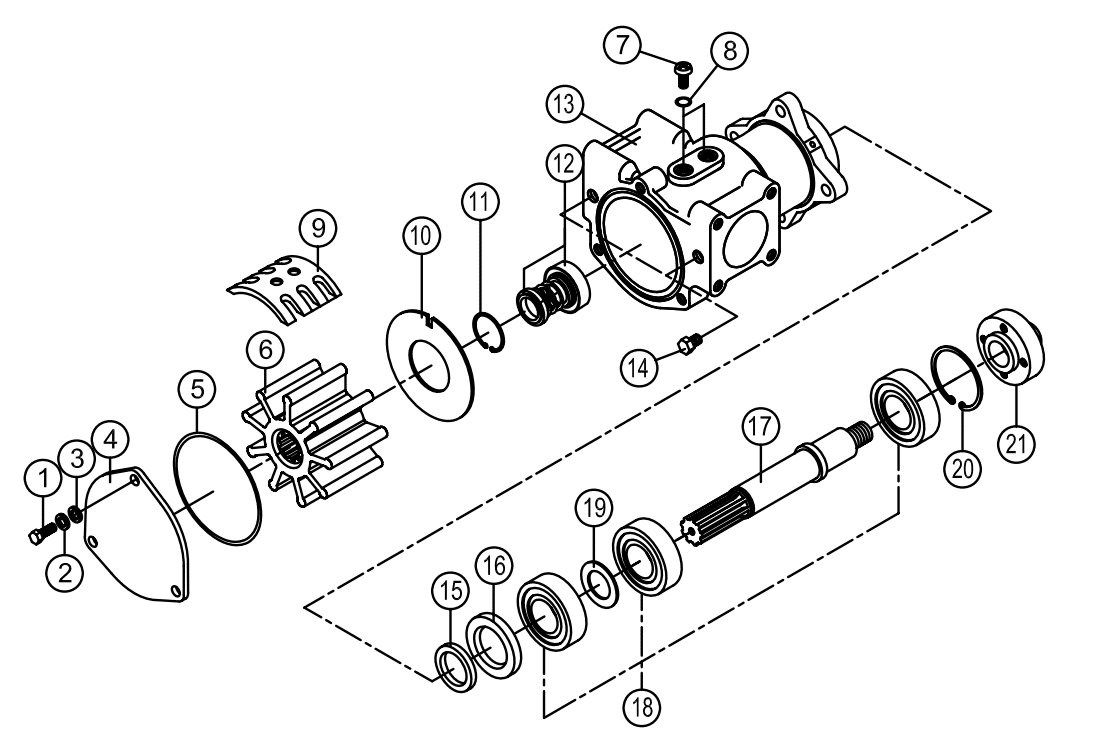

The depiction to the right is the “make or break” part of any marine engine seawater pump design. If you are familiar with the internal design of the Cummins/Sherwood OEM 17XX or 27XX pumps, and understand “Seawater Pump Design 101”, then the differences are clear as to what we have accomplished in our designs working around the main constraint we had – Any new pump that replaces the OEM pump, MUST be 100% “PLUG & PLAY” for the vessel owner. Our Triple Bearing and “greaseable” shaft support cartridge in our SMX-QSB pump, no cir-clip groove in this highly stressed shaft support area, a rear non-loaded reversed lip seal and water slinger keep our sealed bearings 100% water free under any condition, and the decades old and proven “Detroit Type” mechanical water seal, along with superior materials used in all of the components is what has separated us from from the factory supplied pumps.

The depiction to the right is the “make or break” part of any marine engine seawater pump design. If you are familiar with the internal design of the Cummins/Sherwood OEM 17XX or 27XX pumps, and understand “Seawater Pump Design 101”, then the differences are clear as to what we have accomplished in our designs working around the main constraint we had – Any new pump that replaces the OEM pump, MUST be 100% “PLUG & PLAY” for the vessel owner. Our Triple Bearing and “greaseable” shaft support cartridge in our SMX-QSB pump, no cir-clip groove in this highly stressed shaft support area, a rear non-loaded reversed lip seal and water slinger keep our sealed bearings 100% water free under any condition, and the decades old and proven “Detroit Type” mechanical water seal, along with superior materials used in all of the components is what has separated us from from the factory supplied pumps.

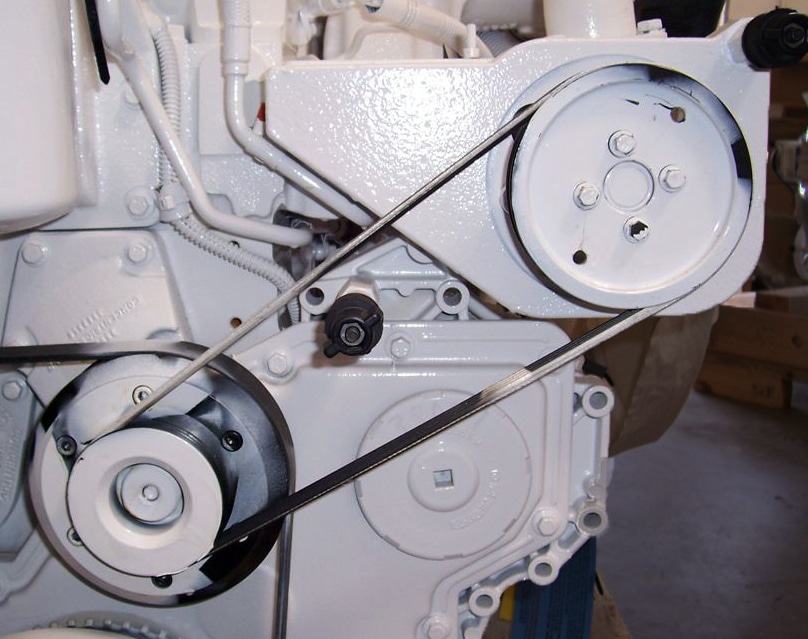

Two key parts to our NEW SMX QSB seawater pump are both the front pulley hub and the shaft.

The hub, is actually removable by unscrewing opposite of pump rotation which allows the easy tear down of the pump for eventual rebuilding. Plus, it has an extended nose that allows for a much easier “stretchy belt” change when the time comes. For those familiar to this procedure, this feature will hit home. Another important feature of the hub design is that it moves the load of the very tight belt closer to the bearings, eliminating undue stress on the front of the shaft.

Our shaft does not use cir-clips to hold the bearings in place. This was and still is another weak point in the OEM design. Plus, our pump shafts are currently being machined from genuine AQ-19 which is purchased from Western Branch Metals, located in the state of Virginia. Next year, as production picks up, we are going to have the shaft “investmant cast” from SS316LN and then machined to further upgrade quality while keeping the price competitive.

For all seawater pump sales being shipped to Canada, please read the following:

For all seawater pump sales being shipped to Canada, please read the following:

Reviews

There are no reviews yet.