Description

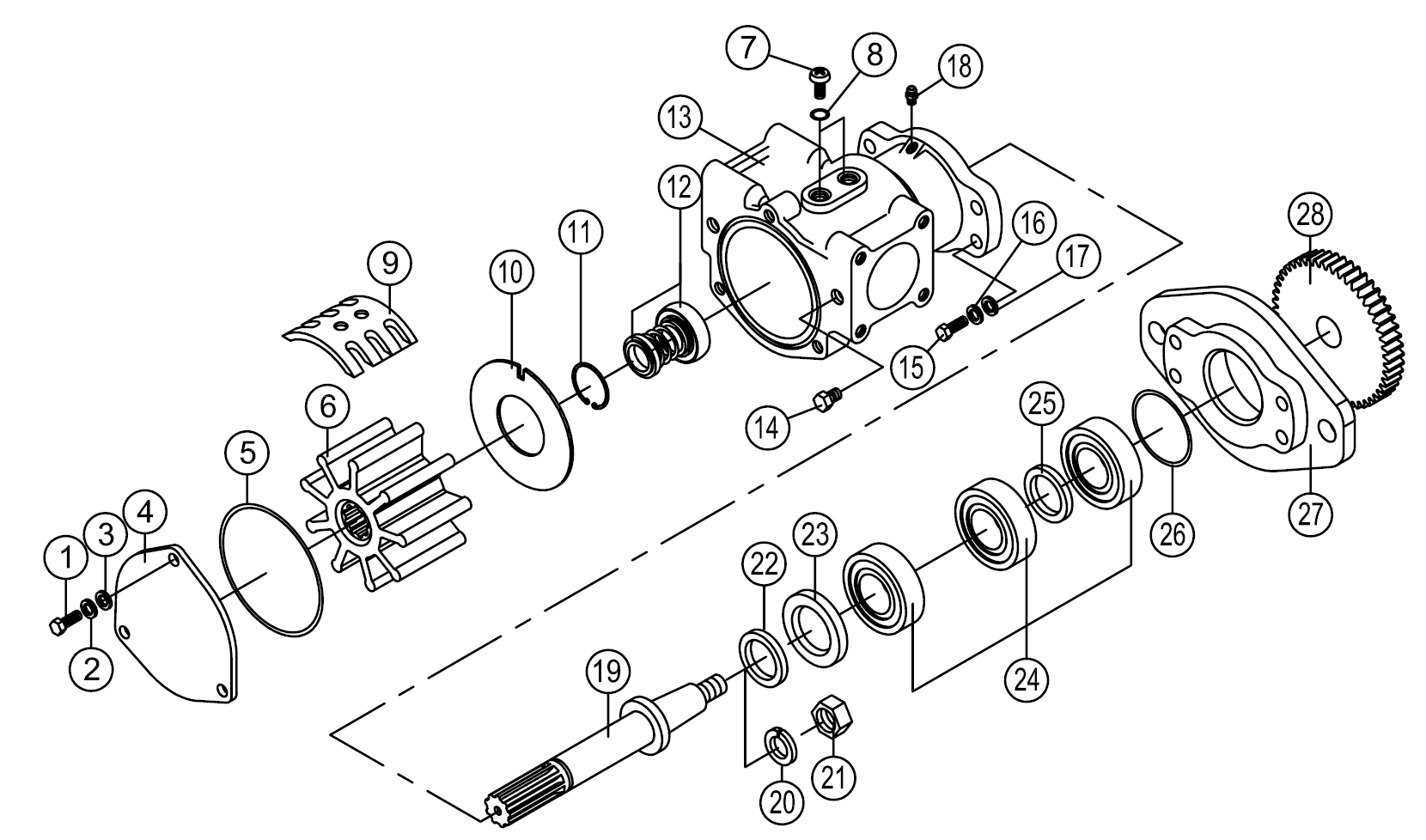

- Exclusive design for 100% “PLUG & PLAY” replacement on all Cummins B & C Diamonds

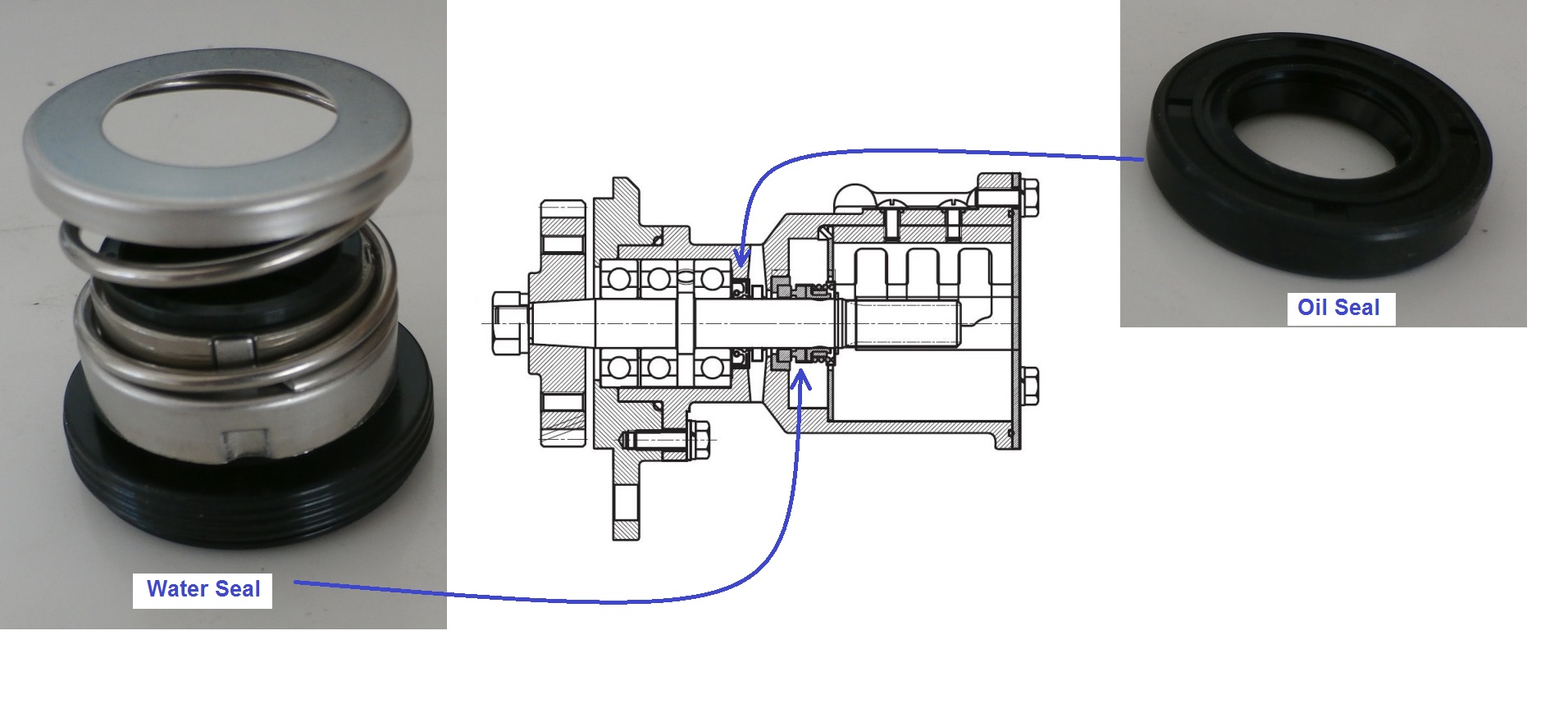

- “Detroit Style” mechanical water seal w/ aft-mounted double lip oil-lubed “oil seal”

- Made from proven seawater resistant alloys of bronze, brass & stainless steel

- Simple rebuilds using commonly available tools, bearings & seals

- Backed up by an exclusive 24 month “no hassle” pump exchange policy

This all started about 1988…

When Cummins released the (infamous to some) 6BTA 300, sometimes referred to as the CPL 970. About that time Sherwood and Cummins struck a deal that allowed Sherwood to become

the exclusive supplier of seawater pumps for them.

What I call “Design Defects” in the new Sherwood Pump that was installed on the new generation Cummins 300B marine engines (1700 series) became apparent soon after its release, and over the 16-17 years that followed, as Sherwood made different versions of this same “base pump,” the number of design defects grew along with the new models. Now keep in mind, as we are not talking about seal and bearing wear/failures here, we are talking about real defects in design that I have never seen with any other seawater pump I have dealt with. By the time their most popular version was released, the 1730 (in about 1995), soon thereafter it was obvious that something had to be done to help solve this seawater pump failure dilemma that was now causing direct harm to my livelihood because this pump was being installed on the new Cummins Diamonds that were now the mainstay of my engine sales and repower part of my business.

As more years past and the flak I was getting about the quality of the Sherwood pumps grew, by early 2005, it was time to become proactive in developing a new pump that would “fit” as a 100% “plug & play” Sherwood 1730 replacement and try to do something that could make this pump more reliable… Our biggest challenge was working around the size constraints of the application as this new pump had to FIT exactly as the 1730 did or we could not market it successfully…

Because of this, we even had to compromise some on both bearing support and shaft size, which was where this pump needed much improvement. Solving the material choice was easy as all we had to do was not use the “junk” metal alloys, but go back to basics-Use proven seawater resistant alloys that have been used for decades by other prominent manufacturers of seawater pumps.

After some searching around, I found a respected company in Korea (already in the seawater pump business) that was willing to work with me in a new design. I had lots of ideas but absolutely no experience in trying to manufacture a seawater pump, and being a “small guy,” had limited funding available for the development. What I did have was the knowledge of what can make a good seawater pump, a marketing plan, and also what we had to do to make the needed improvements. Well about 18 months of work with 100’s of e-mails and drawings going back and forth, we came up with what is our SMX 1730 (& SMX 1727) seawater pump and now offer what we think is a superior “mouse trap”. Our improvements speak for themselves and address all of the issues that are inherent with the Sherwood pump design. Cost ??-of course the new pump cost more than we hoped for, but with the cost of copper-based alloys tripling from early 2005 thru mid 2006, this did not help.. But in the end, we are still price competitive and now offer the end user a “choice” for the seawater pump used for the very popular Cummins 6BTA 5.9 and 6CTA 8.3 Diamond (and commercial counterparts) diesels.

eric3 (verified owner) –

Do not waste your $ and time buying an original Sherwood while Seaboard makes these. The spare impeller alone is worth the price difference. However the real clincher is the ease with which the impeller can be changed- literally a 20 min process now with this design. Just remove the S/S face plate, pull out the old impeller, dab-grease the new impeller splines, and reinstall. A life-saver underway!

kelbritz –

Was time to swap the impeller this morning on our 2 year old SMX pump. Truly no comparison to the identical task on a Sherwood pump. Thank you Tony!!!! In and out, cleaned up and away in less than an hour. didn’t have to remove anything to get to it. And that built-in extractor feature worked flawlessly. After having done 7 Sherwood impeller swaps (and replacing 3 lousy leaky seal Sherwood pumps . . .) over the years on our boat, this was truly amazing. No more dropped shaft keyway to hunt around for in the bilge because of the splined shaft on the SMX. This pump might be the best maintenance upgrade we’ve ever done to our 6BTA. Hardest part was actually getting the o-ring to stay in it’s groove long enough to put the face plate back on. I will suggest looking carefully at the picture when you do this swap, there’s not much room once you’ve got your hands and a socket wrench in there, you definitely want to find the right 3 bolts that hold that face plate on, and not the other 2 very similar bolt heads that are quite nearby. Again, thank you Tony and the whole team that made the SMX pumps a reality !!!!

jim wick (verified owner) –

Perfect fit for my 6cta’s. 45 minutes on the first one because I missed a seal and removed hoses. I did have a trivial question and Corey or brenden took my call and gave me free advice like they always do. The second one I had the right size wrenches out, left the hoses on the elbows and I was in and out in 15 minutes. I am almost excited to do an impeller change next year. Well worth the money

Dan Ramirez (verified owner) –

A high quality pump! Much better than the Sherwood. I like the splined impeller.

Truly plug and play