For the Cummins Marine B & C series engines released in the late 80’s to early 90’s, the idler pulley arrangement had an unacceptable failure rate. The engineers updated the idler pully support arrangement and that basically solved the issue about 1994-ish.

For those engines that did not come with the upgrade idler pulley support system, a “hands-on” approach to this is what this article is about. Lots of pictures below:

For those wishing to do this themselves————–Replace the original 10mm bolt with a Grade 8 – 7/16 x 2 3/4″ bolt and nut. This requires drilling the spacer (new or old style) to 29/64″ and drilling the engine bracket to 7/16″. You can either reuse the front washer by drilling it to 29/64″ or use a new 7/16 high quality flat washer in its place (much easier). For the newer engines, you have to remove the sheet metal cap (like a thin freeze plug) to gain access to the bolt. You do not need to replace this and I recommend that you don’t. Both pulleys use industry standard 6203 sealed bearings (worth about $ 10 each or less) and can be changed with minimum effort if this is needed (about every 5000 hours in a clean dry environment—more often if wet). When doing this upgrade, be sure you lubricate the parts/bolt/nut (common grease) and torque to yield (about 45-55 ft lbs).

Back to drilling. I recommend this procedure for any B & C over 2 years old and also for any new engine in a single engine boat.

The spring idler assembly has also had a few upgrade over the years, but none of these were from failure problems. There has been some casting changes, spring rate modifications, and ???. The good news w/ the tensioner is that it costs less than 10 yrs ago by a substantial margin. The current # is 3936201 and it’s about $100 or #3934818 , about $90. This belt system has proven to be a good reliable system (other than this idler pulley bolt) with belt life typically at 2000+ hrs. With a little effort, even that problem can be solved.

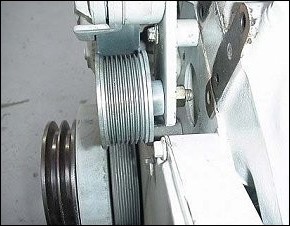

The two hard parts of the project that you need to do. Bore out the “spacer / bushing / sleeve” (what ever you want to call it), and drill out the bracket to accept a “real bolt”.

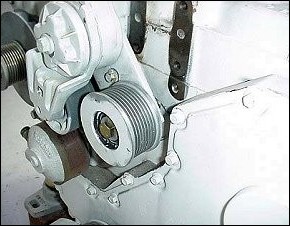

Finished Repair / Bored spacer, a 7/16″ Grade 8 bolt & Nut. Assembeled with some grease and torqued to about 45-55 ft lbs – Done right, no issues ever again!!

Note: I have resurrected this article from about June 2000 era as I am now seeing the issue re-surface again with the new Cummins REMAN Marine engine packages. Could they have gone backwards ???